Ignition chamber of quartz diffusion furnace

A technology of ignition chamber and diffusion furnace, applied in the field of diffusion furnace, can solve the problem of low safety of thermocouple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The following is attached Figure 1-6 The application is described in further detail.

[0082] The embodiment of the present application discloses an ignition chamber of a quartz diffusion furnace.

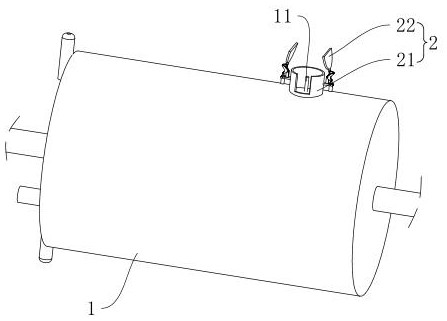

[0083] refer to figure 1 , an ignition chamber of a quartz diffusion furnace includes an ignition chamber body 1, a temperature measuring couple 11 is pierced on the ignition chamber body 1, and one end of the temperature measuring couple 11 extends into the ignition chamber body 1 for temperature measurement, and the temperature measuring couple 11 The other end is located outside the ignition chamber body 1, and the ignition chamber body 1 is provided with a protective device 2 for shielding the temperature measuring couple 11 outside the ignition chamber body 1.

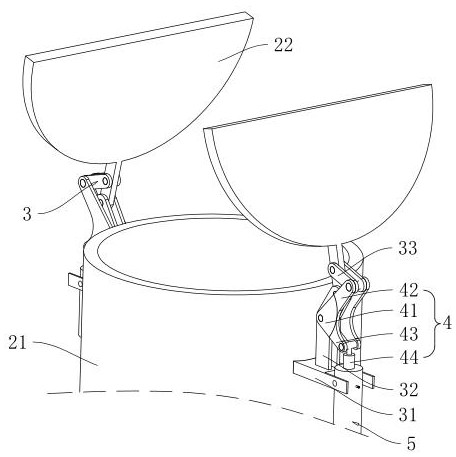

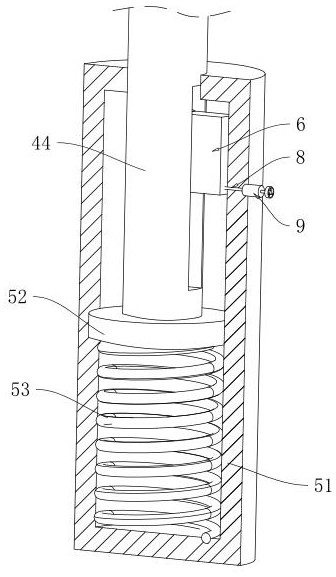

[0084] refer to figure 1 and figure 2 The protective device 2 includes a protective cover 21 and a protective blade 22. The protective cover 21 is a hollow cylinder and is fixedly connected to the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com