Low-temperature thin-layer quick-heating cascade anaerobic pyrolysis system and solid waste pyrolysis system based on system

A low temperature thin layer, temperature control system technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of easy coking, high operating costs, and extensive system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: A low-temperature thin-layer rapid-heat cascade anaerobic pyrolysis system, an external feeding device and a pyrolytic carbon receiving hopper, characterized in that the low-temperature thin-layer rapid-heat cascade anaerobic pyrolysis system includes solid waste extrusion Conveying system, heating temperature control system and heat preservation device; the solid waste extrusion conveying system and heating temperature control system are set in the heat preservation device; the heat preservation device is provided with a pyrolysis gas outlet; the solid waste extrusion conveyance system It is used to transport the solid waste after extrusion and thinning; the heating and temperature control system is used to heat and pyrolyze the solid waste after extrusion and thinning.

[0052]The upper roller extruding conveying assembly and the lower roller extruding conveying assembly, which are used to extrude solid waste, roll in reverse; the rollers divide the syste...

Embodiment 2

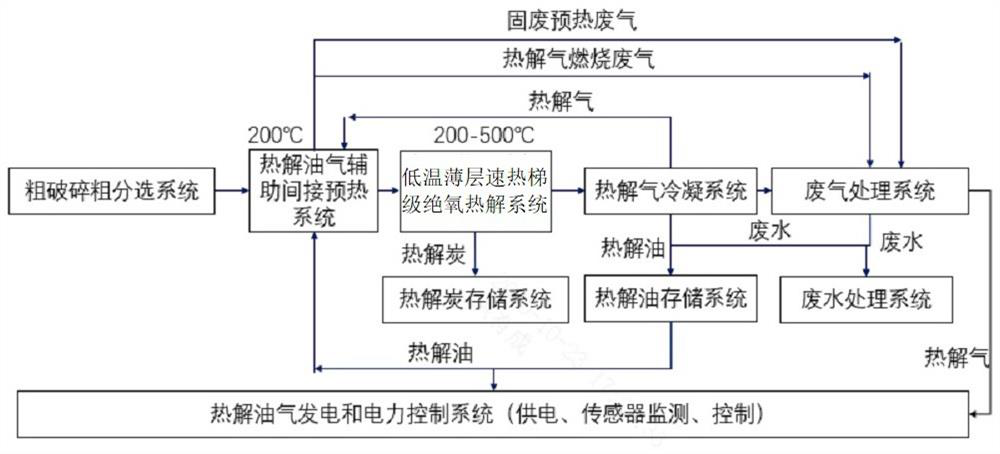

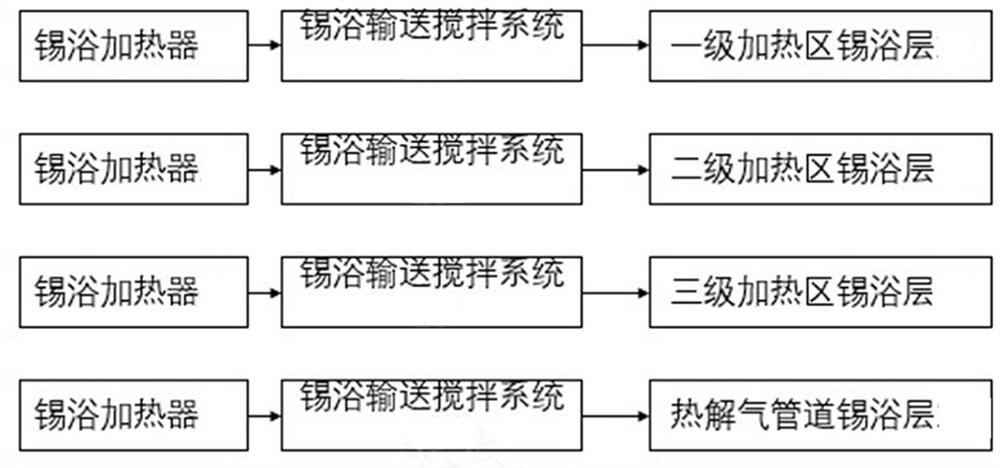

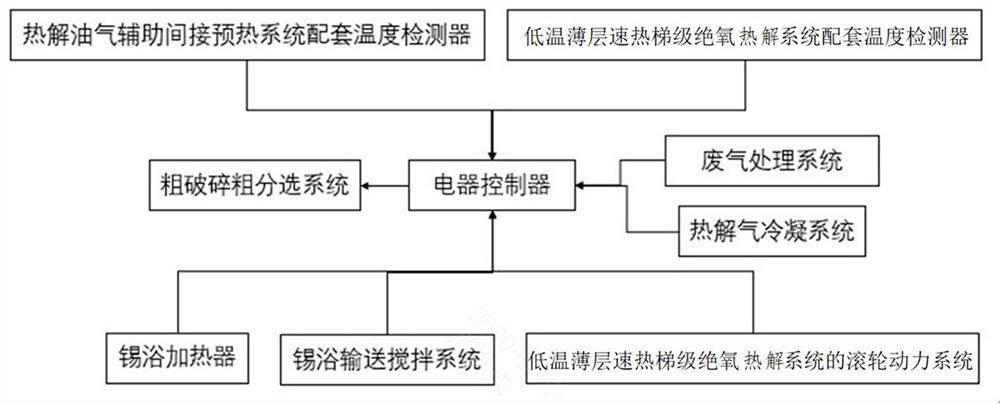

[0053] Example 2: The solid waste pyrolysis system provided by the present invention consists of a coarse crushing and coarse separation system, an indirect preheating system for pyrolysis oil and gas auxiliary heat, a low-temperature thin-layer rapid-heat cascade aerobic pyrolysis system, a pyrolysis gas condensation system, The exhaust gas treatment system, pyrolysis carbon storage system, pyrolysis oil storage system, pyrolysis oil and gas power generation and power control system, and wastewater treatment system are composed of 9 parts. The core part is the low-temperature, thin-layer, rapid-heat, cascade anaerobic pyrolysis system, other coarse crushing and coarse separation systems, pyrolysis oil and gas auxiliary heat indirect preheating system, pyrolysis gas condensation system, waste gas treatment system, and pyrolysis carbon storage system , pyrolysis oil storage system, electrical monitoring and control system, pyrolysis oil and gas power generation and electrical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com