Boiler system capable of improving burn-off rate of pulverized coal and reducing NOx generation amount

A technology of burnout rate and production volume, which is applied in the transportation of non-flammable liquid/gas, regulation of fuel supply, combustion air/fuel supply, etc., which can solve technical and economic difficulties in implementation, large amount of changes to the entire boiler system, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

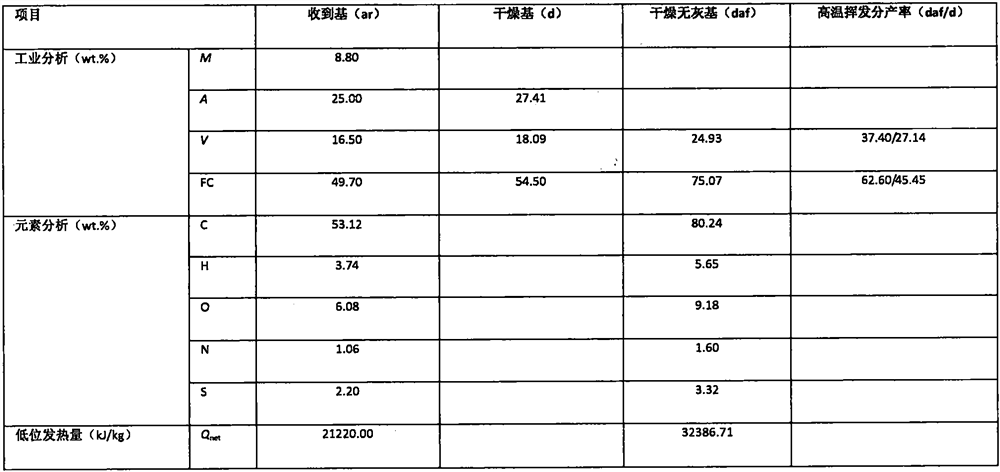

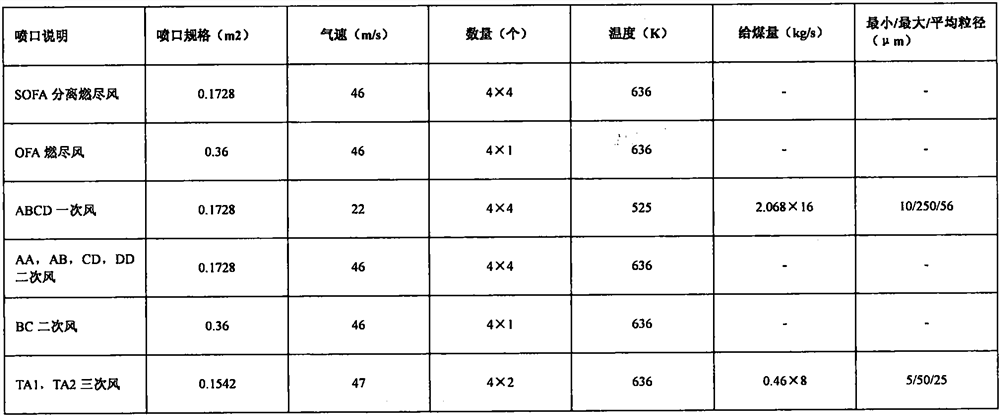

[0011] For a clearer understanding of the technical content of the present invention, the following figure 1 As an example to elaborate:

[0012] figure 1 In order to comply with the idea of the present invention, a type of reconstruction plan for isolating the wind system, the object of specific investigation is a 330MW four-corner tangentially fired pulverized coal furnace, which adopts π-shaped layout and staged combustion. The scope of the modified isolated wind system is within the range of the double dotted line. 1 is the isolation air mixer, which can be one or more parallel connection; 2 is the booster fan, which can be one or more parallel connection; 3 is the hot air flow adjustment valve; 4 is the isolation air temperature adjustment valve; Flow regulating valve.

[0013] In this scheme, the isolated air is a mixture of two streams of air, one cold and one hot. The two streams of air are provided by the blower. The cold air is drawn from the front of the air pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com