Oil-proof and high-impact-resistant U-shaped sealing gasket for underwater ship

A technology for marine and gaskets, applied in the direction of engine sealing, transmission parts, engine components, etc., can solve problems such as marine environmental pollution, waste of resources, damage, etc., achieve scientific and reasonable design, increase flexibility and resilience, strengthen the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

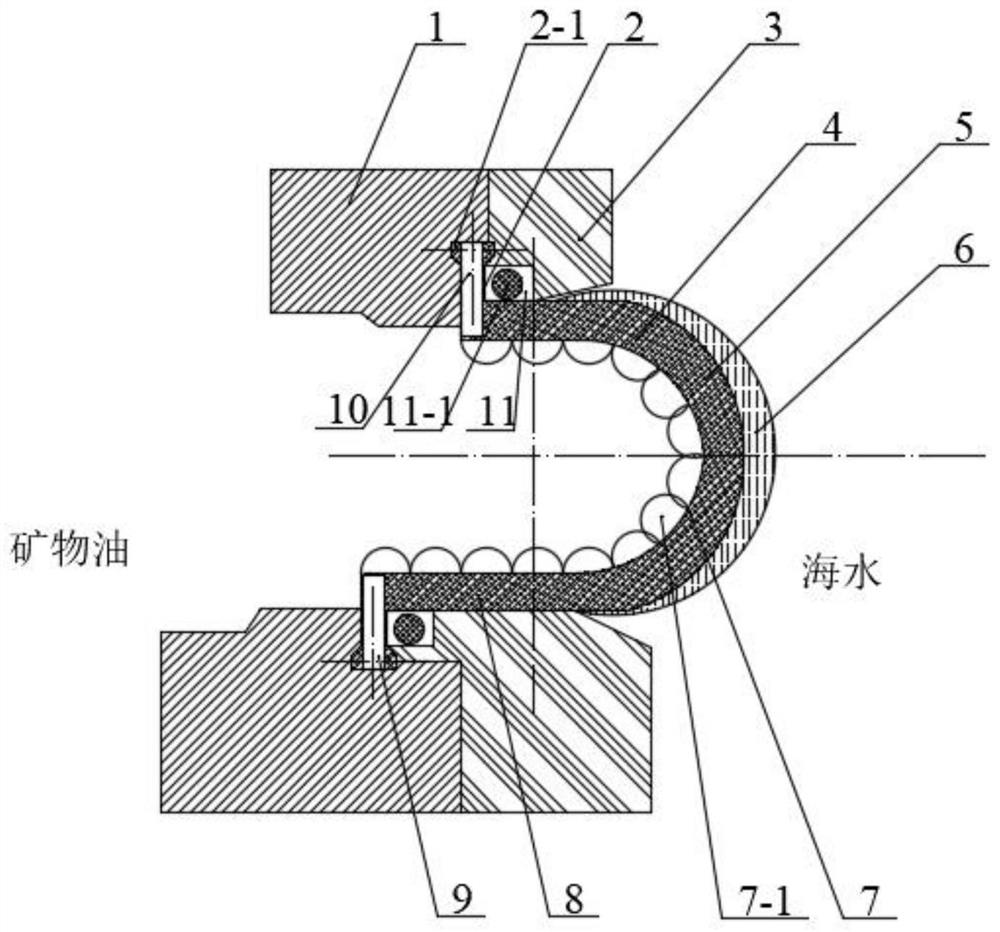

[0020] An oil-proof, high-impact-resistant U-shaped gasket for underwater ships, such as figure 1 As shown, the body is a flexible U-shaped sealing ring structure, and a nitrile rubber lip body 6 is integrally extended on the outer side of the flexible U-shaped sealing ring and the seawater contact surface, and additionally installed on the inner side of the flexible U-shaped sealing ring and the mineral oil contact surface There is an oil-proof sealing layer 7, and several unit buffering oil-proof nitrile rubber particles 7-1 are arranged on the surface of the oil-proof sealing layer.

[0021] The flexible U-shaped sealing ring includes a first rubber extension body 2, a second rubber extension body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com