Environment-friendly eye protection paper and preparation method thereof

An eye-protecting paper, an environmentally friendly technology, applied in special paper, paper, papermaking, etc., can solve the problems of low wet paper strength and severe paper web shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

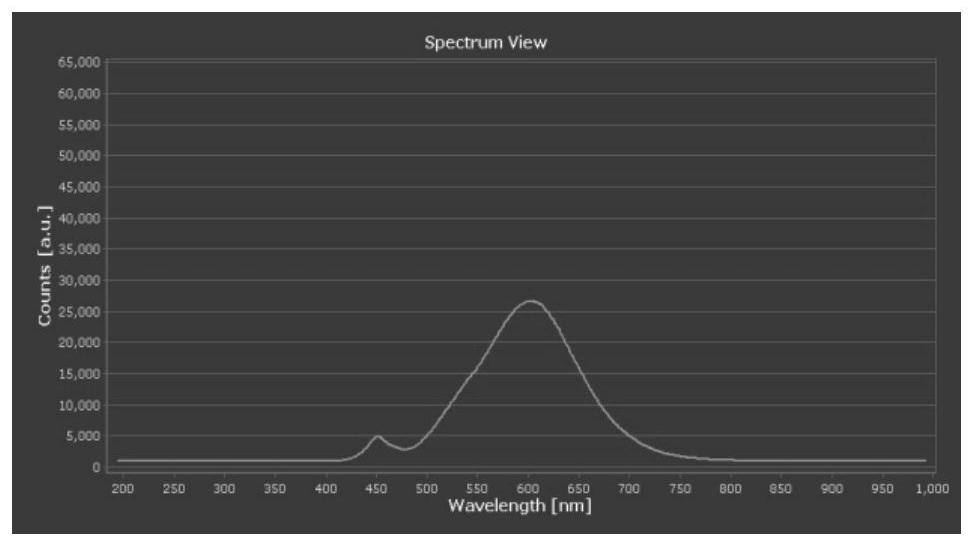

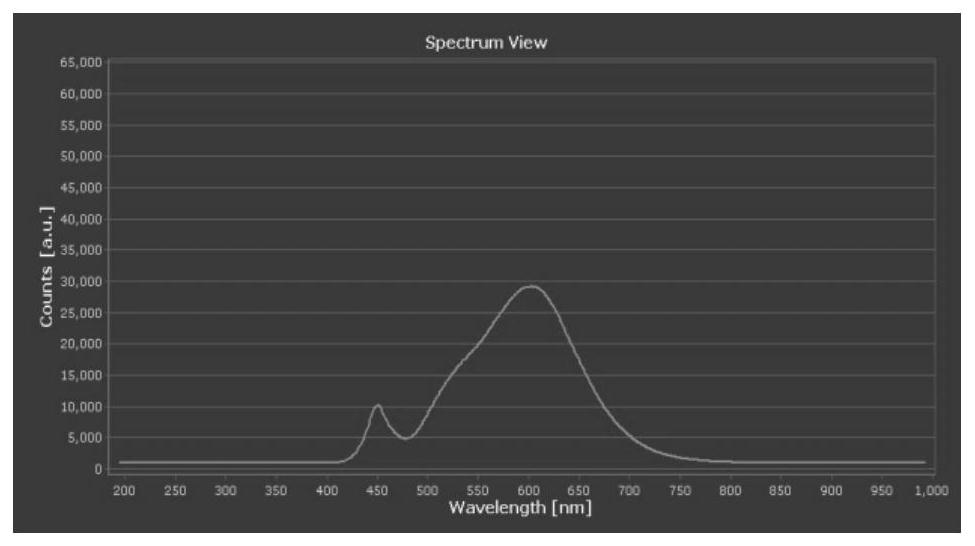

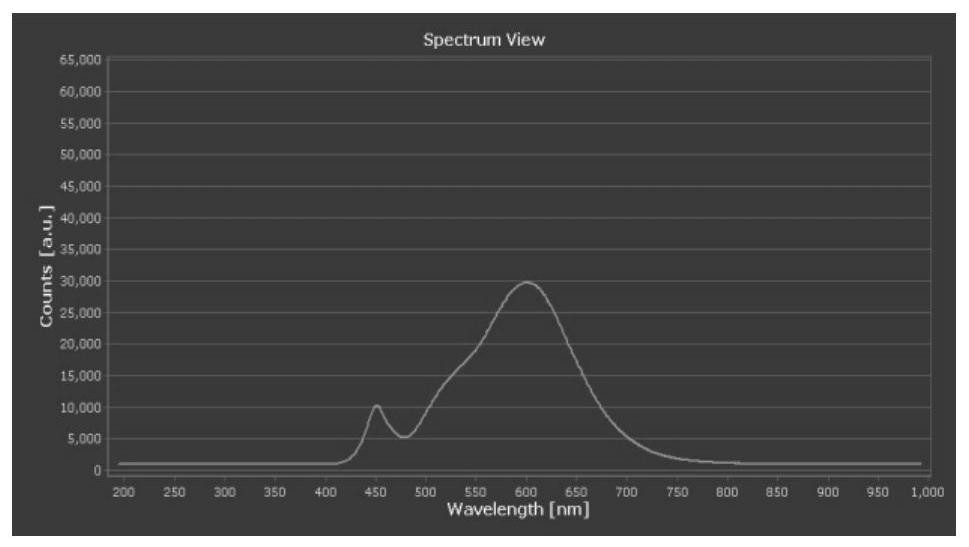

Image

Examples

preparation example Construction

[0032] The invention relates to an environment-friendly eye protection paper and a preparation method thereof, which reflects light softly and does not cause damage to human eyes. The key to the eye protection paper is that it can achieve the purpose of eye protection and environmental protection through coordination and cooperation of various factors such as color vision perception, reading efficiency, eye environment, environmental benefits, physical and chemical properties, and economic benefits. The main technical characteristics of the technical solution of the present invention:

[0033] (1) The CIELab parameter range of the eye protection paper is L: 90-95, a: 3-10, b: 18-25, the opacity is 88-95%, and the whiteness is 60-70% ISO. The "CIELab" is a uniform color space commonly used at present, and is also the most commonly used color representation method for paper. The three variables "L, a, b" defined by CIELab color space are respectively expressed as follows: L is ...

Embodiment 1

[0050] (1) Preparation of hematoxylin pulp: cutting and pulverizing the hematoxylin so that its length does not exceed 30 mm. Remove the silt, fly ash, and other sundries mixed in the raw materials. Add 6% of the mass of hematoxylin aluminum sulfate, add an aqueous solution twice the mass of hematoxylin, the aqueous solution contains 1% sodium hydroxide by mass percentage, mix and heat to 30°C for 2 hours, transport to a refiner for The dissociation is uniform, the mass fraction of the refining concentration is 20%, and the degree of beating after refining is 25°SR.

[0051] (2) Mix bagasse pulp, bamboo pulp, waste paper pulp, and hematoxylin pulp according to the ratio of mass parts 40:25:34.5:0.5, and transport them to a refiner for beating treatment. The mass fraction of refining concentration is 25%. , the degree of percussion after refining is 25°SR. Add fillers and additives to adjust the pulp, adjust the pH to 6-8, and then make paper.

[0052] The types and parts by...

Embodiment 2

[0056] (1) Preparation of hematoxylin pulp: cutting and pulverizing the hematoxylin so that its length does not exceed 30 mm. Remove the silt, fly ash, and other sundries mixed in the raw materials. Add aluminum sulfate 10% of the mass of hematoxylin, add an aqueous solution 3 times the mass of hematoxylin, the aqueous solution contains 5% sodium hydroxide by mass percentage, mix and heat to 60°C and soak for 1.5 hours, and transport to a refiner for The dissociation is uniform, the mass fraction of the refining concentration is 25%, and the beating degree after refining is 30°SR.

[0057] (2) Mix bagasse pulp, bamboo pulp, waste paper pulp, and hematoxylin pulp according to the ratio of mass parts 33:28:38:1, and transport them to a refiner for beating treatment. The mass fraction of refining concentration is 28%. , the degree of knocking after refining is 30°SR. Add fillers and additives to adjust the pulp, adjust the pH to 6-8, and then make paper.

[0058] The types and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com