Color-changing edible food packaging film and preparation method thereof

A food packaging film and film-forming technology, applied in the field of packaging materials, can solve the problems of relying on artificial synthesis, consumption, and unfavorable resource-saving society construction, etc., to achieve the effect of ensuring food health, broad application prospects, and good moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of embodiment 1 discoloration edible food packaging film

[0031] Specifically include the following steps:

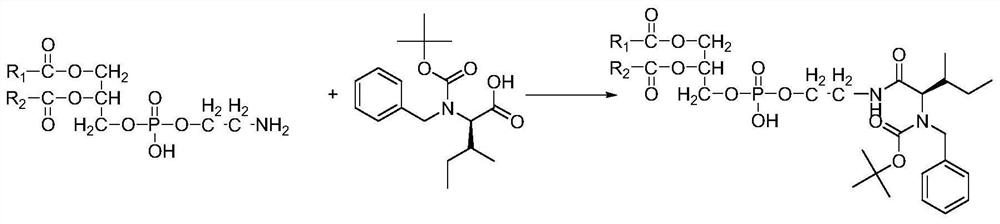

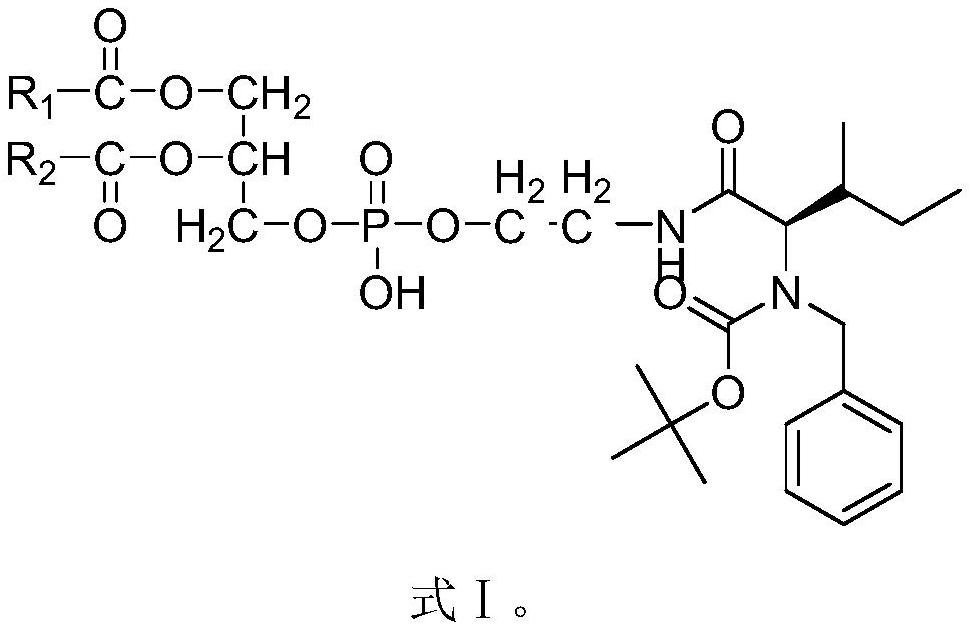

[0032] S1. Refer to attached figure 1 , Dissolve 125g of phosphatidylethanolamine in ethanol, the solid-to-liquid ratio is 1:1g / mL, add 5g of condensing agent dicyclohexylcarbodiimide and 15g of fish collagen peptide, heat to 35°C for 3h, and place in vacuum Degas in a vacuum oven at 0.01MPa for 5 minutes to remove air bubbles, filter, and wash the product with a buffer solution with a pH of 6 for 5 times;

[0033] S2. Pulverize the phenolphthalein flakes, grind them down to below 100 mesh, and grind them to below 1000 mesh through a ball mill to obtain phenolphthalein fine powder;

[0034] S3. Add 100g of the product in step S1 to water, solid-to-liquid ratio 1:0.5g / mL, and add 0.5g nisin and 0.1g natamycin, stir and mix evenly, further add 0.5g phenolphthalein fine powder, 10000r / min Homogenize for 1 min to obtain a homogenized solut...

Embodiment 2

[0035] The preparation method of embodiment 2 discoloration edible food packaging film

[0036] Specifically include the following steps:

[0037] S1. Refer to attached figure 1, Dissolve 170g of phosphatidylethanolamine in ethanol with a solid-to-liquid ratio of 1:5g / mL, add 10g of condensing agent dicyclohexylcarbodiimide and 25g of fish collagen peptide, heat to 45°C for 5h, and place in vacuum Degas in a vacuum oven at 0.1 MPa for 5-7 minutes to remove air bubbles, filter, and wash the product with a buffer solution with a pH of 8 for 10 times;

[0038] S2. Pulverize the phenolphthalein flakes, grind them down to below 100 mesh, and grind them to below 1000 mesh through a ball mill to obtain phenolphthalein fine powder;

[0039] S3. Add 100g of the product in step S1 into water, the solid-to-liquid ratio is 1:1g / mL, and add 1.5g nisin and 1g natamycin, stir and mix evenly, and further add 1g phenolphthalein fine powder, 12000r / min After massaging for 3 minutes, a homoge...

Embodiment 3

[0040] The preparation method of embodiment 3 discoloration edible food packaging film

[0041] Specifically include the following steps:

[0042] S1. Refer to attached figure 1 , Dissolve 150g of phosphatidylethanolamine in ethanol with a solid-to-liquid ratio of 1:3g / mL, add 7g of condensing agent dicyclohexylcarbodiimide and 20g of fish collagen peptide, heat to 40°C for 4 hours, and place in a vacuum Degas in a vacuum drying oven at 0.05MPa for 6 minutes to remove air bubbles, filter, and wash the product 7 times with a buffer solution with a pH of 7;

[0043] S2. Pulverize the phenolphthalein flakes, grind them down to below 100 mesh, and grind them to below 1000 mesh through a ball mill to obtain phenolphthalein fine powder;

[0044] S3. Add 100g of the product in step S1 to water, solid-to-liquid ratio 1:0.7g / mL, and add 1g nisin and 0.5g natamycin, stir and mix evenly, further add 0.7g phenolphthalein fine powder, 11000r / mL Homogenize for 2 minutes to obtain a homog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com