Modification preparation method of soft polyacrylic resin microspheres

A technology of polyacrylic resin and polymethyl methacrylate, which is applied in the field of modification and preparation of soft polyacrylic resin microspheres. Industrial production and market application, etc., to achieve the effect of easy drying and crushing, no impact on optical properties and scratch resistance, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

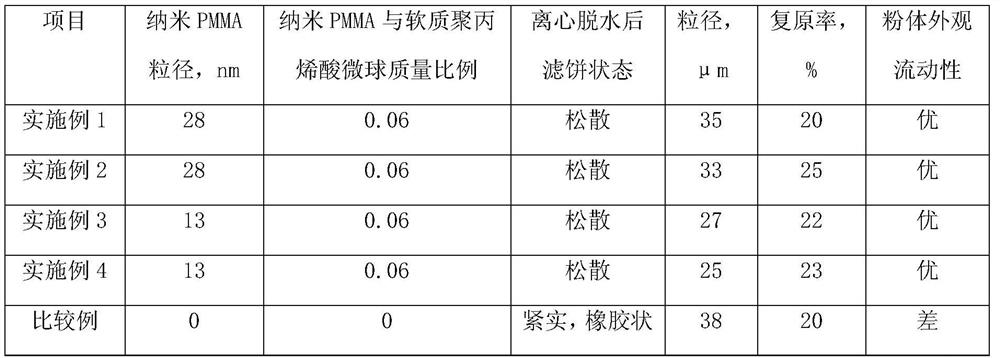

Examples

Embodiment 1

[0034] 1. Preparation of nanoscale polymethyl methacrylate particle dispersion

[0035] Place a four-neck flask equipped with a stirrer, thermometer, reflux condenser and nitrogen tube in a super constant temperature water bath, add 900 parts of deionized water, then add 6 parts of sodium succinyl sulfonate, stir and dissolve to form an emulsion, Then add 100 parts of methyl methacrylate, continue to stir, raise the temperature to 65°C, add 1 part of ammonium persulfate, and maintain this temperature for 4 hours to obtain a dispersion of nano-sized polymethyl methacrylate particles.

[0036] 2. Preparation of modified soft polyacrylic resin microspheres

[0037] Lower the above dispersion to room temperature, take 150 parts, add 37.5 parts of 10% polyvinyl alcohol solution, stir and dissolve evenly, then add 850 parts of deionized water, and further stir evenly to form a low-concentration dispersion system;

[0038] Dissolve 2.5 parts of benzoyl peroxide in 200 parts of methy...

Embodiment 2

[0043] 1. Preparation of nanoscale polymethyl methacrylate particle dispersion

[0044] Place a four-neck flask equipped with a stirrer, thermometer, reflux condenser and nitrogen tube in a super constant temperature water bath, add 900 parts of deionized water, then add 6 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, stir and dissolve into Then add 100 parts of methyl methacrylate to the emulsion, continue to stir, raise the temperature to 75°C, add 1 part of ammonium persulfate, and maintain this temperature for 4 hours to obtain a dispersion of nano-sized polymethyl methacrylate particles.

[0045] 2. Preparation of modified soft polyacrylic resin microspheres

[0046] Lower the above dispersion to room temperature, take 150 parts, add 30.5 parts of 10% sodium polyacrylate solution, stir and dissolve evenly, then add 850 parts of deionized water, and further stir to form a low-concentration dispersion system.

[0047] Dissolve 2.5 parts of azobisisobutyron...

Embodiment 3

[0052] 1. Preparation of nanoscale polymethyl methacrylate particle dispersion

[0053] Place a four-neck flask equipped with a stirrer, thermometer, reflux condenser and nitrogen tube in a super constant temperature water bath, add 900 parts of ethanol, then add 10 parts of sodium lauryl sulfate, stir to dissolve into an emulsion, and then Add 100 parts of methyl methacrylate, continue to stir, raise the temperature to 60°C, add 1 part of potassium persulfate, and maintain this temperature for 4 hours to obtain a dispersion of nano-sized polymethyl methacrylate particles.

[0054] 2. Preparation of modified soft polyacrylic resin microspheres

[0055] Lower the above dispersion to room temperature, take 150 parts, add 15 parts of 8% hydroxyethyl cellulose solution, stir and dissolve evenly, then add 850 parts of ethanol, and stir further to form a low-concentration dispersion system.

[0056] Dissolve 2.5 parts of azobisisoheptanonitrile in 100 parts of n-butyl acrylate, 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com