Environment-friendly agate glaze and preparation process thereof

A preparation process and agate glaze technology are applied in the field of environment-friendly agate glaze and its preparation process, which can solve the problems of poor physical and chemical properties such as plasticity and fire resistance, low appearance quality and mechanical resistance, and achieve enhanced opacity and appearance. Improved quality and mechanical strength, reduced glaze curling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

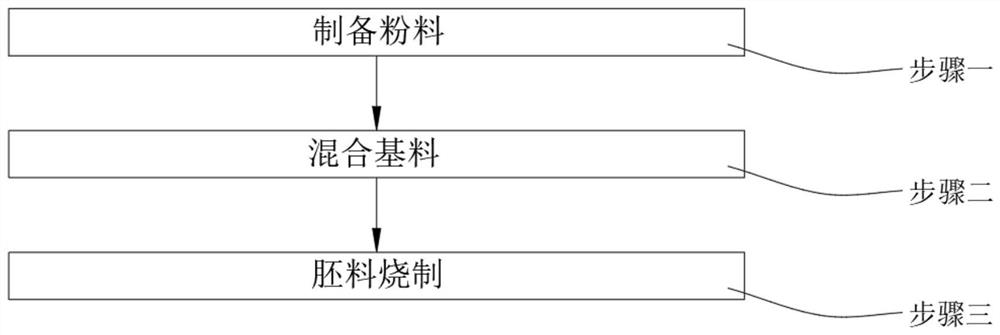

[0022] see figure 1 , the present invention provides a technical solution: an environment-friendly agate glaze prepared from the following raw materials:

[0023] The raw materials are as follows in parts by weight: 25 parts of agate stone, 15 parts of plant ash, 1 part of magnesium oxide, 3 parts of iron oxide, 0.6 part of nano-titanium dioxide, 3 parts of feldspar, 5 parts of diatomaceous earth, 1 part of antibacterial agent, 4 parts of quartz, 5 parts of talc, 2 parts of wollastonite and 18 parts of distilled water.

[0024] In this embodiment, specifically: the feldspar is any one of white feldspar or yellow feldspar or a mixture of both, the particle size of the nano-titanium dioxide is 150um, and the particle size of the magnesium oxide and iron oxide is 50um .

[0025] A kind of environment-friendly type agate glaze preparation process, comprises the following steps:

[0026] Step 1. Preparation of powder: put agate, feldspar, talc, quartz and wollastonite into a cor...

Embodiment 2

[0035] see figure 1 , the present invention also provides a technical solution, which is different from Embodiment 1 in that: an environment-friendly agate glaze is prepared from the following raw materials:

[0036] The raw materials are as follows in parts by weight: 30 parts of agate stone, 12 parts of plant ash, 1 part of magnesium oxide, 2 parts of iron oxide, 1 part of nano-titanium dioxide, 4 parts of feldspar, 7 parts of diatomaceous earth, 2 parts of antibacterial agent, 5 parts of quartz, 7 parts of talc, 3 parts of wollastonite and 122 parts of distilled water.

[0037] In this embodiment, specifically: the feldspar is any one of white feldspar or yellow feldspar or a mixture of both, the particle size of the nano-titanium dioxide is 200um, and the particle size of the magnesium oxide and iron oxide is 250um .

[0038] A kind of environment-friendly type agate glaze preparation process, comprises the following steps:

[0039] Step 1. Preparation of powder: put ag...

Embodiment 3

[0048] see figure 1 , the present invention also provides a technical solution, which is different from Embodiment 1 in that: an environment-friendly agate glaze is prepared from the following raw materials:

[0049] The raw materials are as follows in parts by weight: agate stone, 35 parts, plant ash 8, parts, magnesium oxide 2 parts, iron oxide 3 parts, nano-titanium dioxide 1.2 parts, feldspar 5 parts, diatomaceous earth 8 parts, antibacterial agent 3 parts , 6 parts of quartz, 8 parts of talc, 4 parts of wollastonite and 25 parts of distilled water.

[0050] In this embodiment, specifically: the feldspar is any one of white feldspar or yellow feldspar or a mixture of both, the particle size of the nano-titanium dioxide is 250um, and the particle size of the magnesium oxide and iron oxide is 350um .

[0051] A kind of environment-friendly type agate glaze preparation process, comprises the following steps:

[0052] Step 1. Preparation of powder: put agate, feldspar, talc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com