Method and system for treating phenol-ammonia wastewater

A technology for removing ammonia wastewater and wastewater, which is applied in the field of coal chemical industry, can solve the problems of large wastewater discharge, difficulty in removing and recycling coal tar, and affecting the normal production of the device, and achieve the effect of low recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

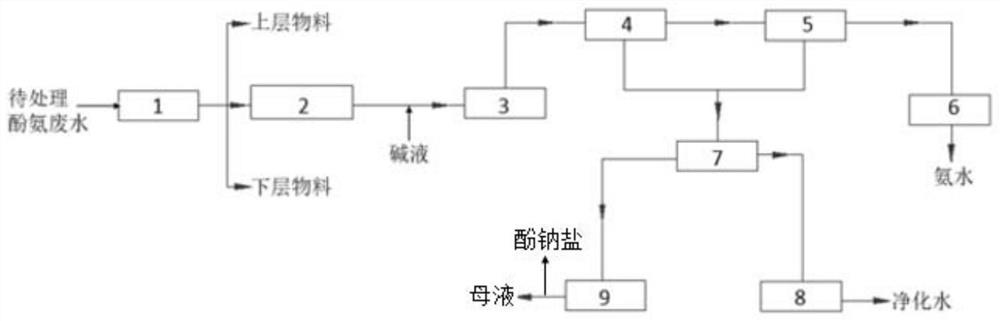

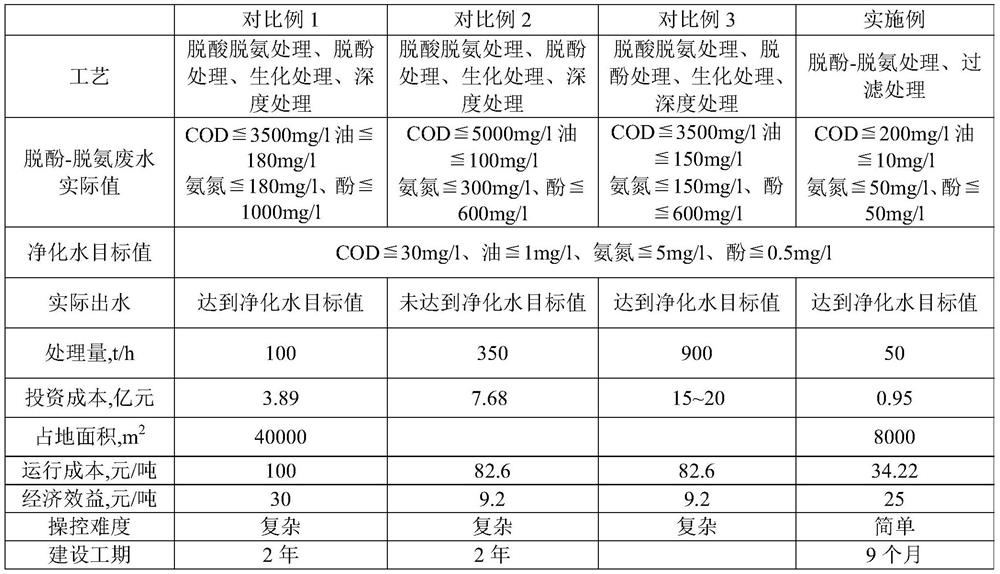

[0079] use as figure 1 The system shown treats phenolic ammonia wastewater, specifically:

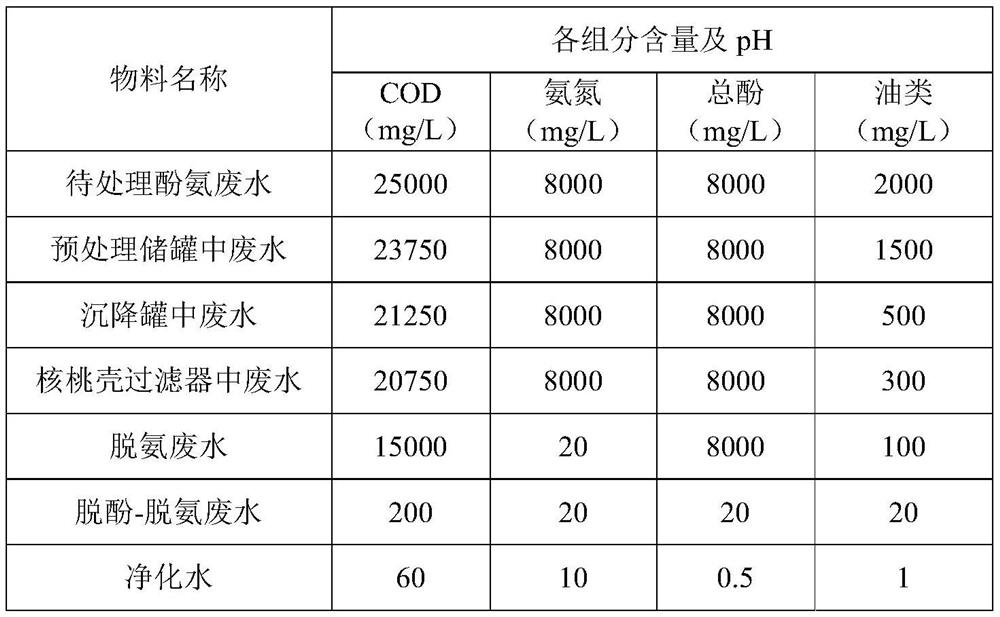

[0080] S1: Make the phenol ammonia wastewater to be treated (flow rate is 50t / h, COD content is 25000mg / L, ammonia nitrogen content is 8000mg / L, total phenol content is 8000mg / L, oil content is 2000mg / L, pH is 9.5, from coal tar hydrogenation process) into the settling tank 1, and add 0.5kg degreasing agent in the settling tank 1, and let it stand at 40°C for 10h to obtain the upper layer material containing light oil, soluble alkali salt and scum and containing dirt mud, sodium phenate, heavy oil and soluble salts in the lower layer, where the total flow rate of the lower layer is 1m 3 / h, the intermediate layer material is introduced into the first filter 2 to filter to obtain degreasing waste water; wherein, the filter medium of the first filter 2 is walnut shell, activated carbon and quartz sand;

[0081] S2: Add lye to the oil-removing wastewater obtained in S1, adjust the pH to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com