Boron-doped graphene aerogel and preparation method and application thereof

A technology of graphene airgel and boron doping, which is applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of lack of full utilization of the electrochemical performance of graphene airgel, and achieve excellent pure capacitance behavior , Excellent rate performance, long cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Mix 100mg of natural graphite powder with 20mL of concentrated sulfuric acid, stir magnetically for 30min, and then add 0.5g of sodium nitrate. After the mixture was cooled to 0°C, 3g of potassium permanganate was slowly added, and heated in a water bath at 40°C for 30 minutes to form a mixed thick slurry. Then add 70 mL of deionized water and 10 mL of H 2 o 2 , the resulting mixed solution was washed with 40 mL of dilute hydrochloric acid, and finally centrifuged at high speed, and the centrifuged washed solution was ultrasonically dispersed in deionized water for 3 h to obtain a GO dispersion with a molar concentration of 1 mg / mL.

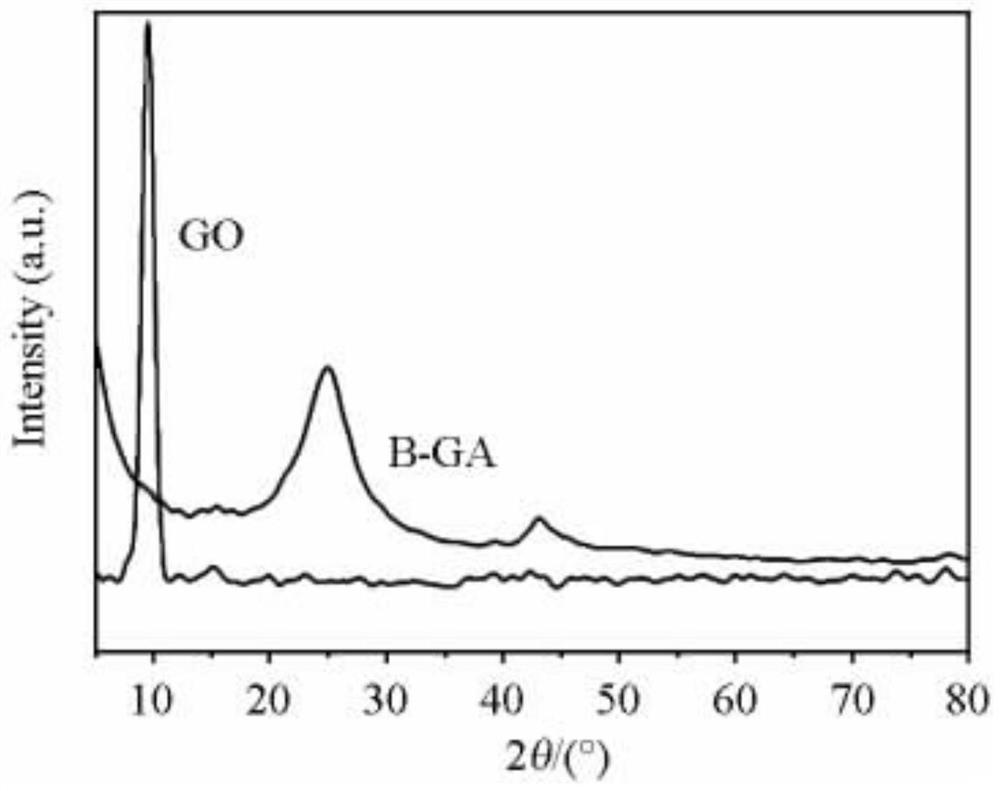

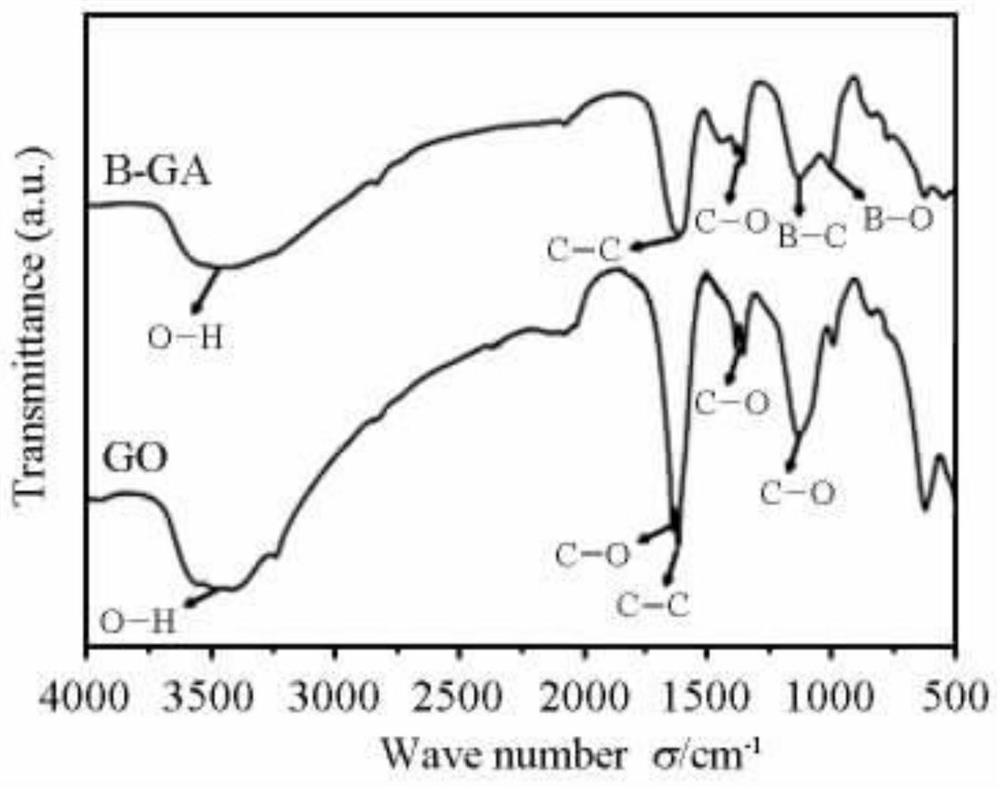

[0043] 2) Evenly mix the GO dispersion with a concentration of 1mg / ml and its mass of 15% boric acid, transfer it to a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it and put it into a 180°C electric constant temperature blast drying oven , the reaction time is 12h, after it is naturally cooled to room temp...

Embodiment 2

[0045] 1) Mix 200mg of natural graphite powder and 20mL of concentrated sulfuric acid, stir magnetically for 30min, and then add sodium nitrate. After the mixture was cooled to 0°C, potassium permanganate was slowly added, and heated in a water bath at 35°C for 30 minutes to form a mixed thick slurry. Then add deionized water and H 2 o 2 , the resulting mixed solution was washed with dilute hydrochloric acid, and finally centrifuged at high speed, and the centrifuged washed solution was ultrasonically dispersed in deionized water for 3 hours to obtain a GO dispersion.

[0046] 2) Evenly mix the GO dispersion with a concentration of 2mg / ml and its mass of 15% boric acid, transfer it to a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it and put it into a 180°C electric constant temperature blast drying oven , the reaction time is 12h, after it is naturally cooled to room temperature, it is taken out for later use. After the surface of the graphene i...

Embodiment 3

[0050] 1) Mix 300mg of natural graphite powder and 20mL of concentrated sulfuric acid, stir magnetically for 30min, and then add 0.5g of sodium nitrate. After the mixture was cooled to 0°C, 3g of potassium permanganate was slowly added, and heated in a water bath at 36°C for 30 minutes to form a mixed thick slurry. Then add 70mL deionized water and 10mLH 2 o 2 , the resulting mixed solution was washed with dilute hydrochloric acid, and finally centrifuged at high speed, and the centrifuged washed solution was ultrasonically dispersed in deionized water for 3 hours to obtain a GO dispersion.

[0051] 2) Evenly mix the GO dispersion with a concentration of 3 mg / ml and its mass of 15% boric acid, transfer it to a polytetrafluoroethylene-lined stainless steel reaction kettle, seal it and put it into a 180°C electric constant temperature blast drying oven , the reaction time is 12h, after it is naturally cooled to room temperature, it is taken out for later use. After the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com