Alternating current magnetic field assisted laser deep penetration welding method for reducing aluminum alloy weld pores

A technology of alternating magnetic field and welding seam porosity, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of joint strength reduction and welding small hole instability, so as to improve joint strength, unlimited workpiece size, The effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

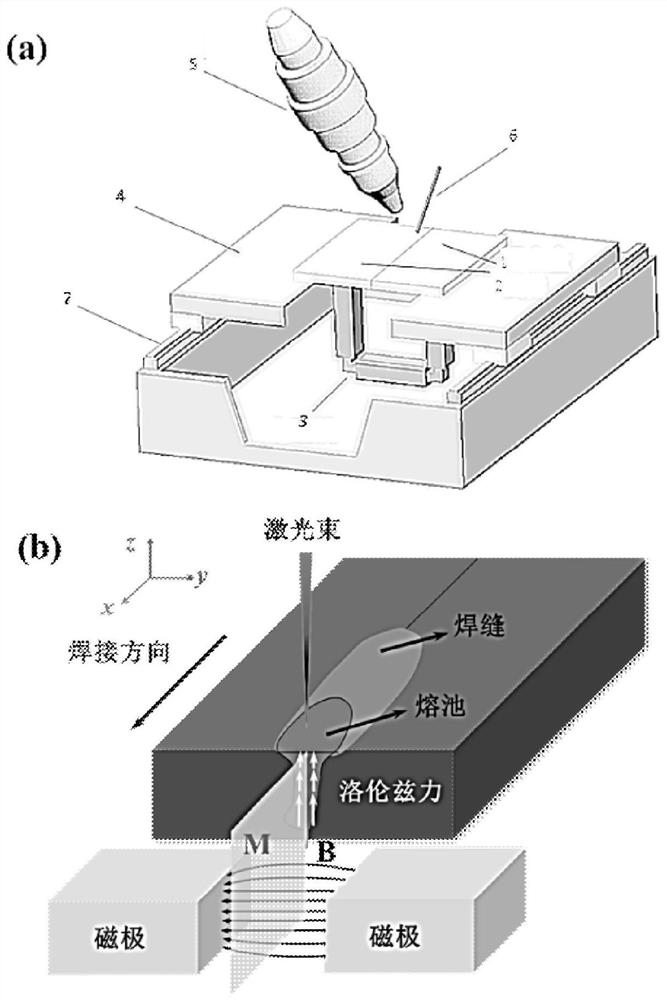

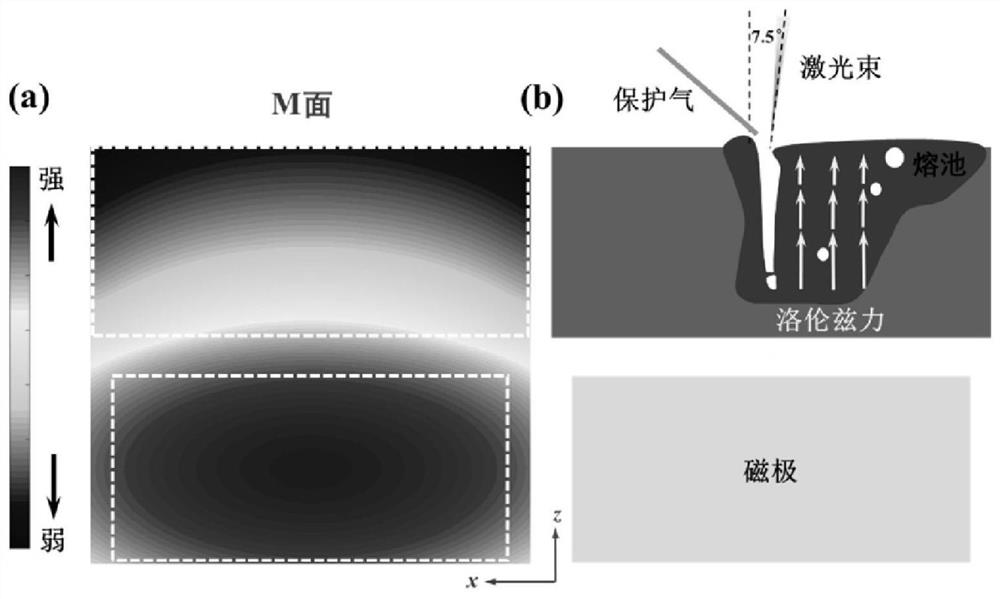

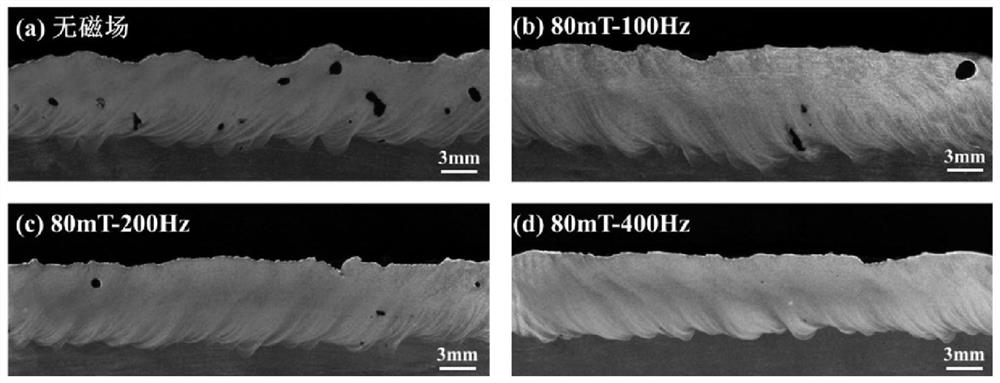

[0017] Such as figure 1 and figure 2 As shown, it is an AC magnetic field-assisted laser deep penetration welding method to reduce the pores of the aluminum alloy weld seam involved in this embodiment. From the analysis of the basic principles, the porosity of the weld seam is largely determined by the frequency of small hole collapse and the ability of bubbles to escape. Two ways. Furthermore, in order to maintain a large penetration depth, it is difficult to reduce the frequency of small hole collapse without changing the original welding parameters. Therefore, a solution is sought from the direction of providing a driving force for accelerated escape of the bubbles. This embodiment specifically includes the following steps:

[0018] Step 1: Take two aluminum alloy plates 1 and 2 with the same thickness and both are 8-12 mm, perform purification treatment on the surface of the part to be welded, and prepare a movable welding system.

[0019] In this embodiment, two A5083 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com