Medium-thickness plate broken line weld joint tracking method based on three-wire crossed swing arc sensing

A technology of arc sensing and arc sensor, which is applied in the direction of arc welding equipment, electrode characteristics, welding equipment, etc., to achieve the effect of improving welding efficiency and quality, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

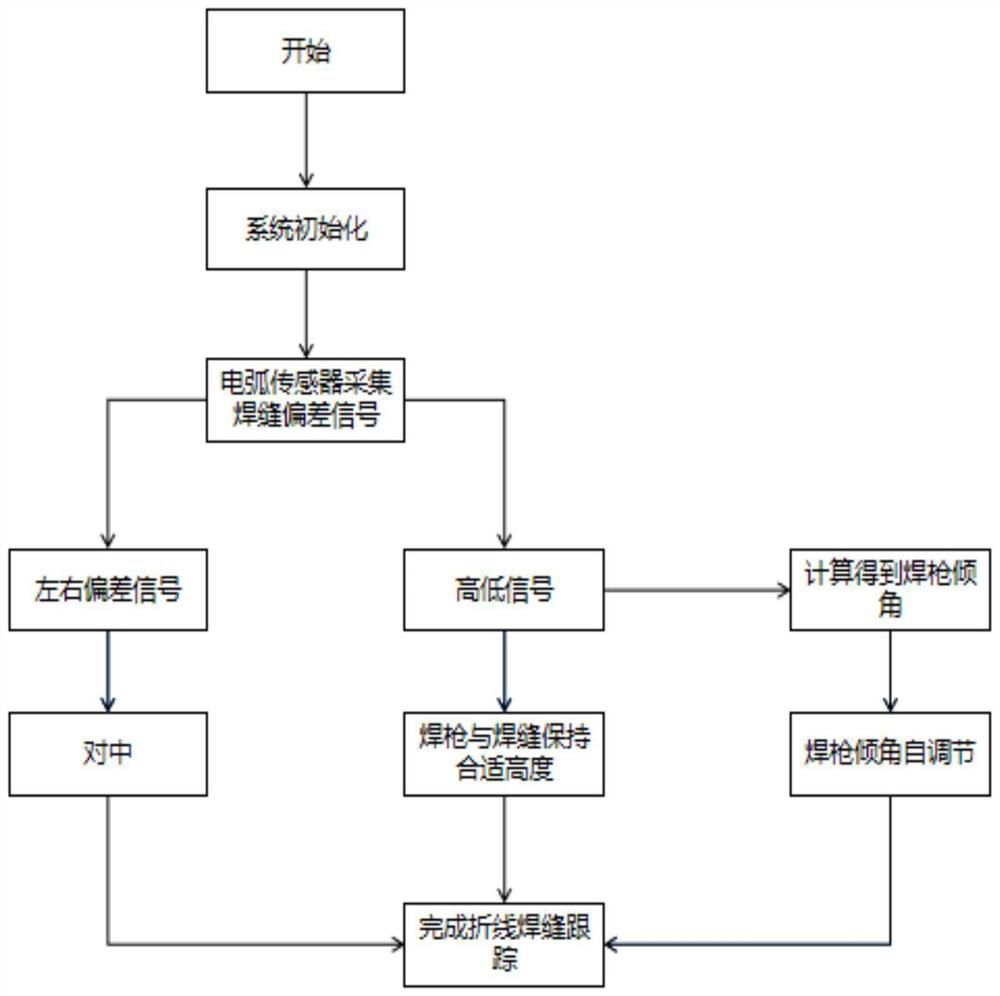

[0017] In order to better express the technical solutions and beneficial effects of the entire invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation cases. However, the embodiments of the present invention are not limited thereto.

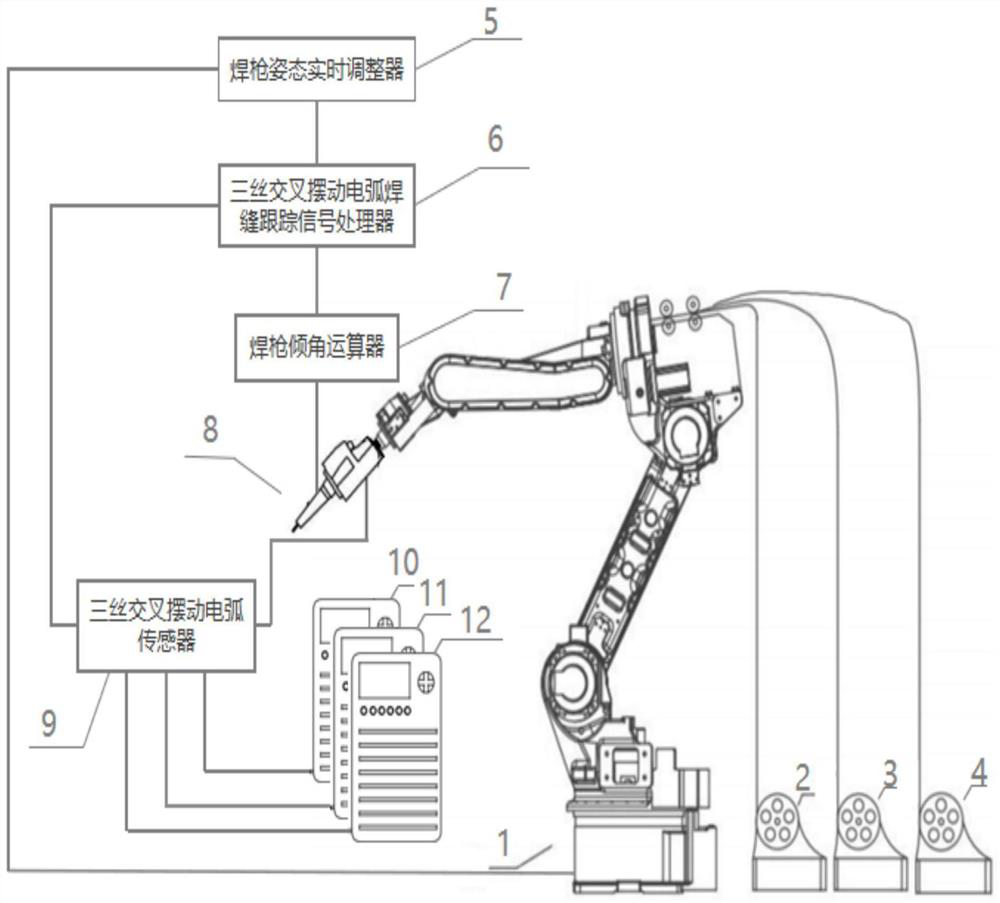

[0018] attached figure 1 Shown is the system hardware connection diagram of the embodiment of the present invention, equipped with a manipulator 1, a wire feeder 2-4, a welding torch attitude real-time adjuster 5, a three-wire cross swing arc seam tracking signal processor 6, and a welding torch inclination calculator 7 , Three wire cross swing arc welding torch 8, three wire cross swing arc sensor 9, welding power source 10-12.

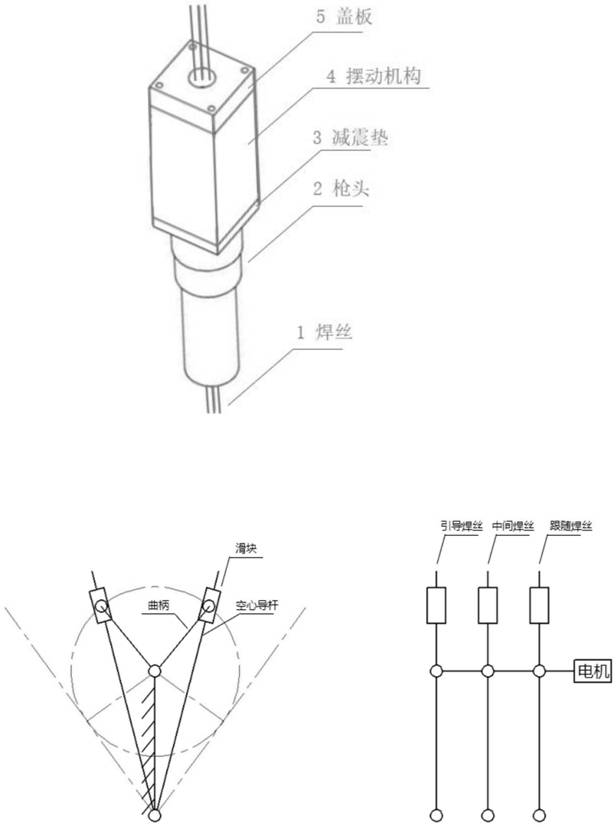

[0019] Three-wire cross swing arc welding torch 8 is a welding torch specially designed for this system, see attached figure 2 , the welding torch is in addition to the torch head 2 and the cover plate 5, it also has a built-in three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com