High temperature gas-cooled reactor helium flow control system and method with incremental adjustment function

A high-temperature gas-cooled reactor and gas flow technology, which is applied in the direction of flow control, control/regulation system, flow control of electrical devices, etc., can solve the problem of non-linear control characteristics, difficulty in precise control, and the need for improvement in dynamic adjustment performance, etc. problem, to achieve the effect of improving stability and flexibility, improving robustness, and controlling stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

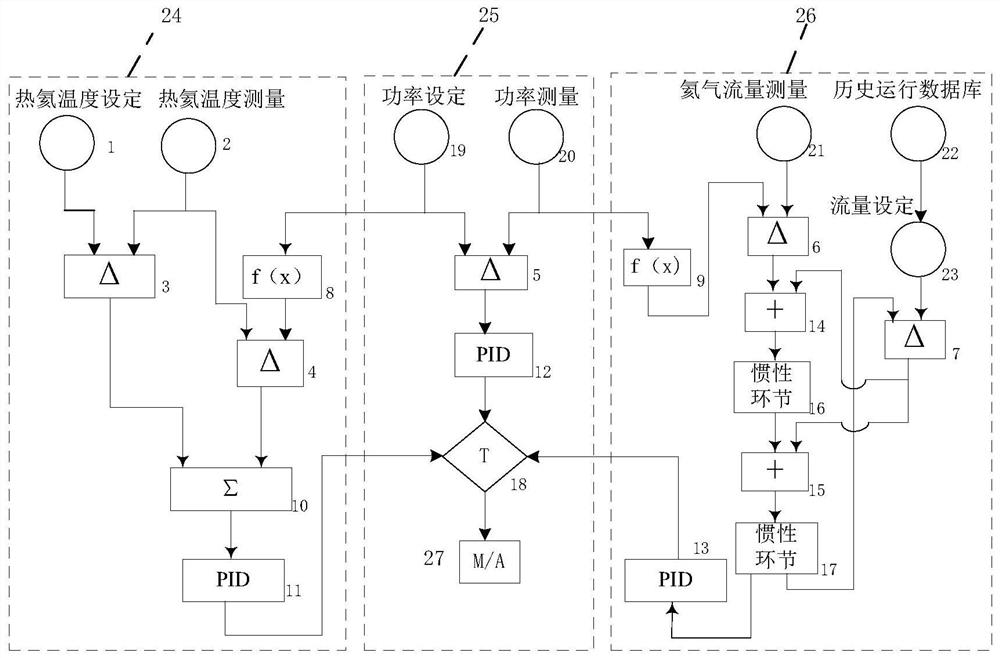

[0022] The invention will be further described in detail below with reference to the accompanying drawings:

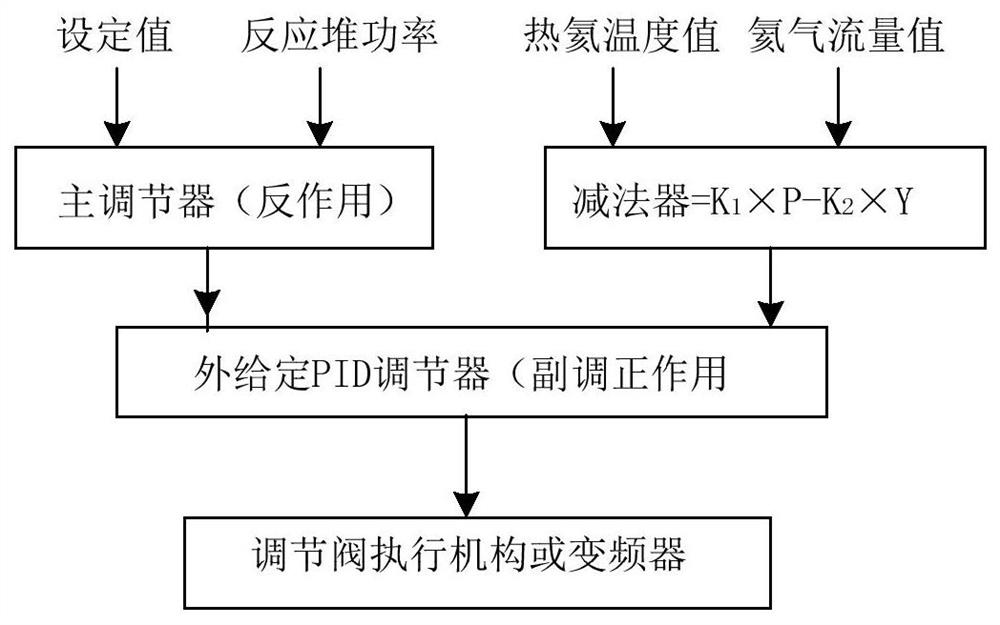

[0023] refer to figure 1 , HTGR helium gas flow control method with incremental adjustment function according to the present invention comprises the steps of:

[0024] 1) obtain temperature measurements helium, and then helium heat temperature set value and the thermal helium temperature measured to obtain a first deviation calculation helium heat temperature deviation value, the thermal helium temperature set value based on the power calculated value is calculated, the heat Calcd for helium temperature thermal helium temperature measurement values to obtain a second deviation calculation heat helium temperature deviation value, the first thermal helium temperature difference value and the second heat helium temperature deviation value is weighted to give a heat temperature helium PID regulator heat helium temperature correction value;

[0025]2) Get the power measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com