Curved pipe type vortex reduction system with high-radius outlet

A radius and curved tube technology, applied in the field of drag reduction, can solve problems such as air flow viscous dissipation, and achieve the effects of reducing flow resistance, reducing dissipation, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The inventors found that the pressure loss in the disc cavity is mainly composed of three parts: the free vortex produced by the gas flowing out of the drum hole from the high radius to the low radius in the disc cavity hinders the radial flow of the air flow; The pressure loss generated inside the tube; when the airflow flows out from the low-radius vortex reducing nozzle, it has a high velocity, and after impacting the rotating shaft, the flow direction changes from radial to axial, resulting in a large pressure loss. Based on this, the present application was developed.

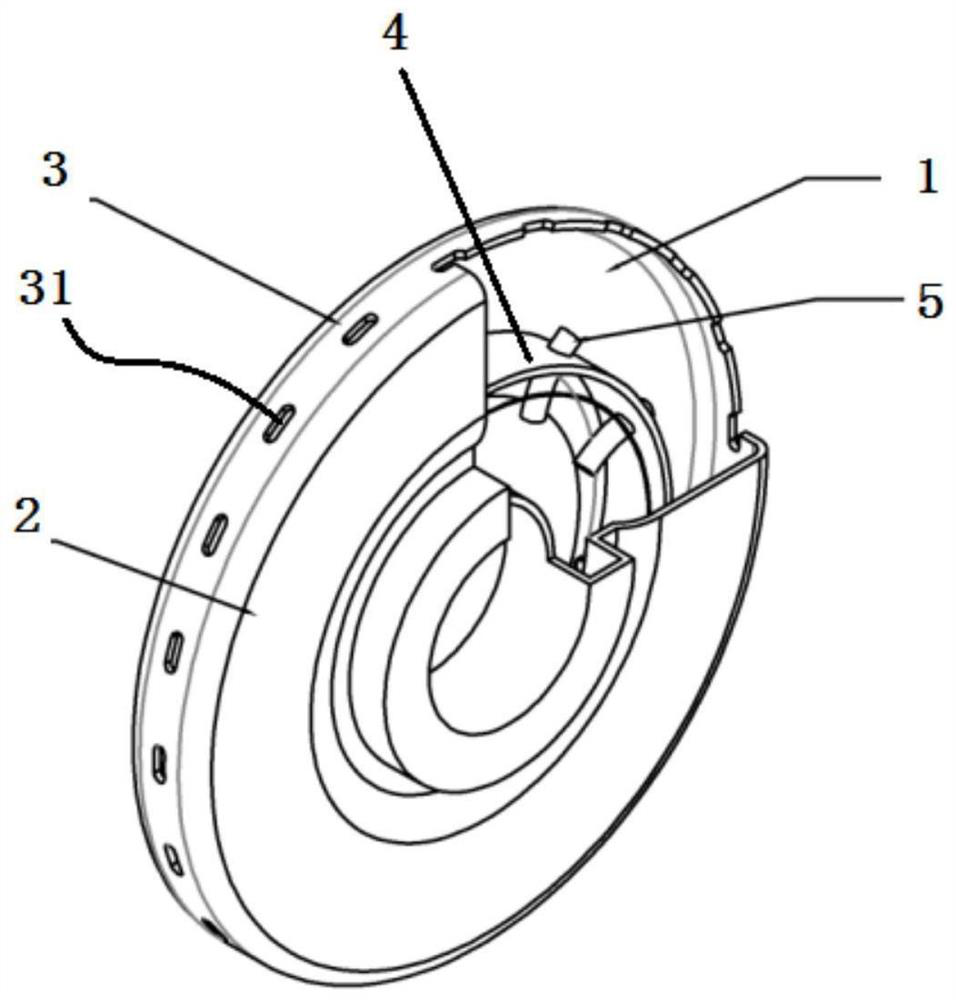

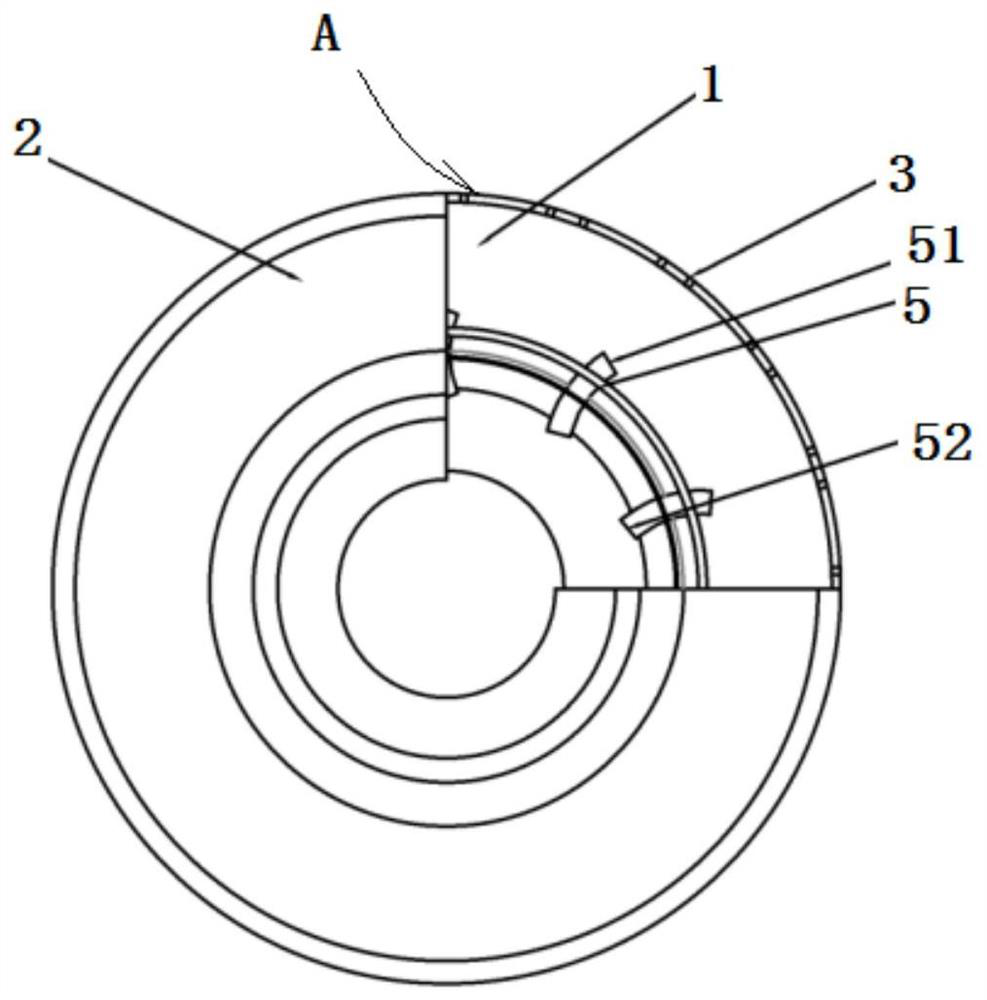

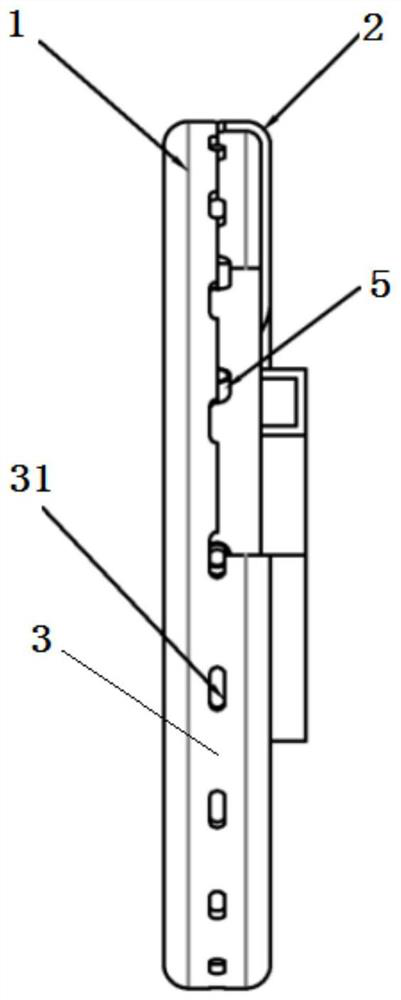

[0035] figure 1 It is a schematic perspective view of a curved tube type vortex reduction system with a high radius outlet according to an embodiment of the present application. figure 2 yes figure 1 Schematic front view of curved tube vortex reduction system with high radius outlet shown. image 3 yes figure 1 Schematic top view of curved tube vortex reduction system with high radius outlet sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com