Gradient tac coating on the surface of a graphite susceptor disk

A graphite base and surface gradient technology, which is applied in the field of gradient TaC coating on the surface of graphite base disks, can solve the problems of easy oxidation, slow decomposition, and easy corrosion of graphite materials, so as to improve thermal matching differences, reduce stress peaks, and relieve stress. The effect of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

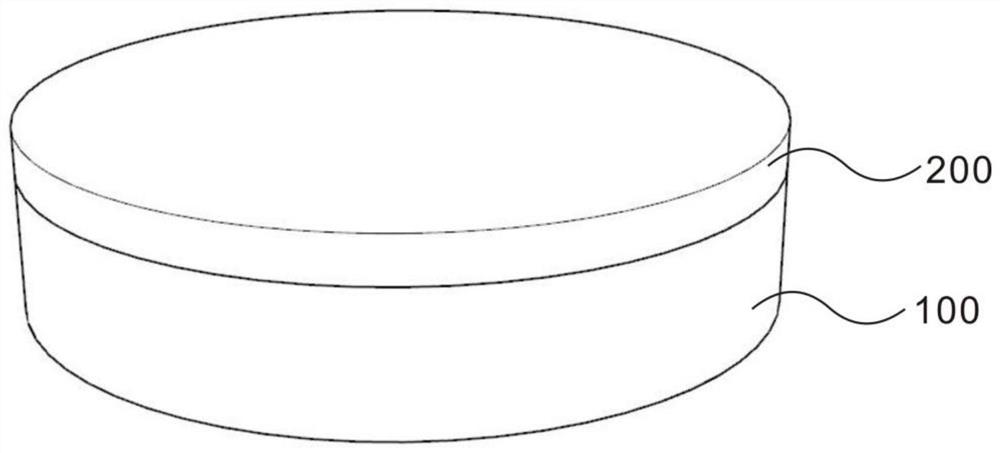

[0027] Such as figure 1 As shown, the present invention provides a gradient TaC coating on the surface of a graphite base plate, including a graphite base plate base 100, and the surface of the graphite base plate base 100 is provided with a gradient TaC coating 200; the gradient TaC coating 200 includes a TaC group Part and C component, the content of TaC component gradually increases from 0% to 100% from the inside to the outside, and the gradient distribution conforms to the law of y=a x linear equation or y=a x 2 Parabolic regular distribution, where y is the percentage of TaC component content, a is a positive number greater than 0, x is the thickness at the interface between the distance gradient TaC coating and the graphite substrate, and x is less than 120 μm, except TaC in the gradient TaC coating And the impurity content outside the C group is less than 5ppm.

[0028] Specifically, the thickness of the gradient TaC coating 200 is 50 μm; the roughness of the gradient...

Embodiment 2

[0041]The present embodiment provides a gradient TaC coating on the surface of a graphite base plate, including a graphite base plate base 100, the surface of the graphite base plate base 100 is provided with a gradient TaC coating 200; the gradient TaC coating 200 includes a TaC component and C component, the content of TaC component gradually increases from 0% to 100% from the inside to the outside, and the gradient distribution conforms to the law of y=a x linear equation or y=a x 2 Parabolic regular distribution, where y is the percentage of TaC component content, a is a positive number greater than 0, x is the thickness at the interface between the distance gradient TaC coating and the graphite substrate, and x is less than 120 μm, except TaC in the gradient TaC coating And the impurity content outside the C group is less than 5ppm.

[0042] Specifically, the thickness of the gradient TaC coating 200 is 100 μm; the roughness of the gradient TaC coating 200 is 1.2 μm.

[...

Embodiment 3

[0055] The present embodiment provides a gradient TaC coating on the surface of a graphite base plate, including a graphite base plate base 100, the surface of the graphite base plate base 100 is provided with a gradient TaC coating 200; the gradient TaC coating 200 includes a TaC component and C component, the content of TaC component gradually increases from 0% to 100% from the inside to the outside, and the gradient distribution conforms to the law of y=a x linear equation or y=a x 2 Parabolic regular distribution, where y is the percentage of TaC component content, a is a positive number greater than 0, x is the thickness at the interface between the distance gradient TaC coating and the graphite substrate, and x is less than 120 μm, except TaC in the gradient TaC coating And the impurity content outside the C group is less than 5ppm.

[0056] Specifically, the thickness of the gradient TaC coating 200 is 120 μm; the roughness of the gradient TaC coating 200 is 1.5 μm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com