Anti-erosion castable for swing flow nozzle as well as preparation method and application of anti-erosion castable

A castable and powder technology, which is applied in the field of metallurgy, can solve problems such as limiting the service life of swing nozzles, high labor intensity of workers, and potential safety hazards of blast furnaces, and achieve the effects of increasing service life, improving corrosion resistance, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

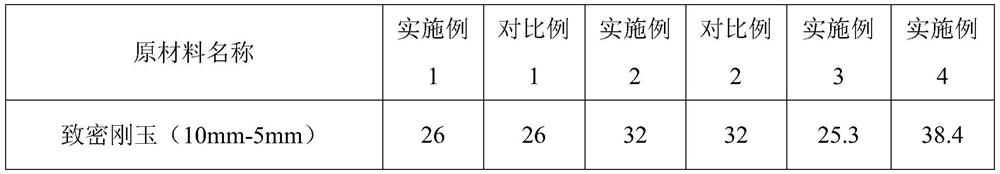

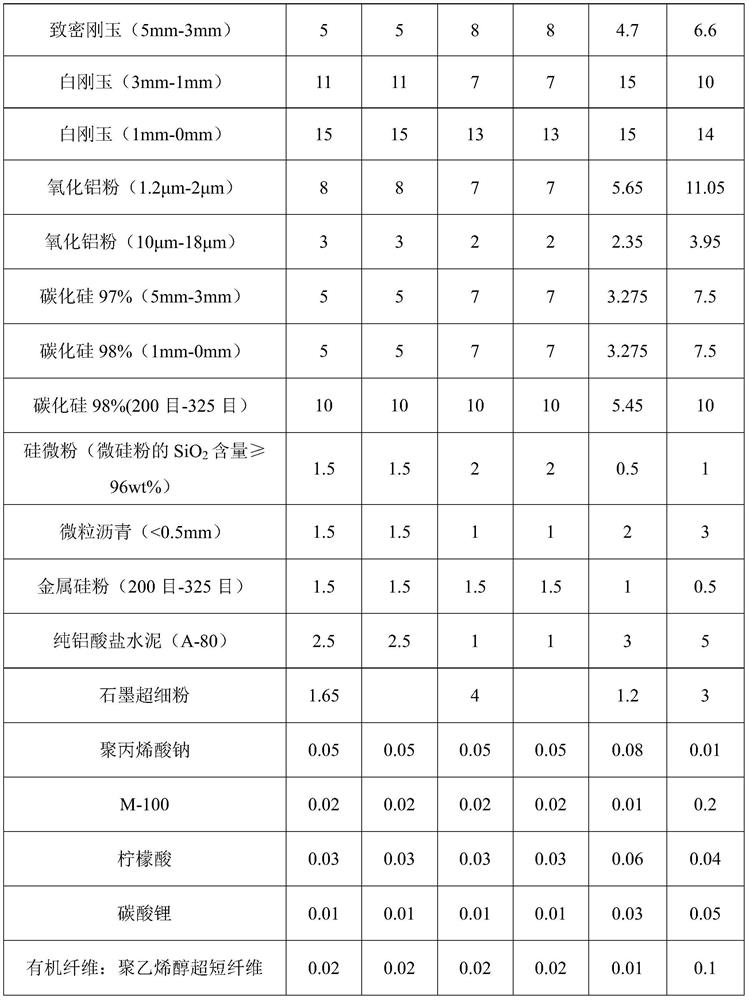

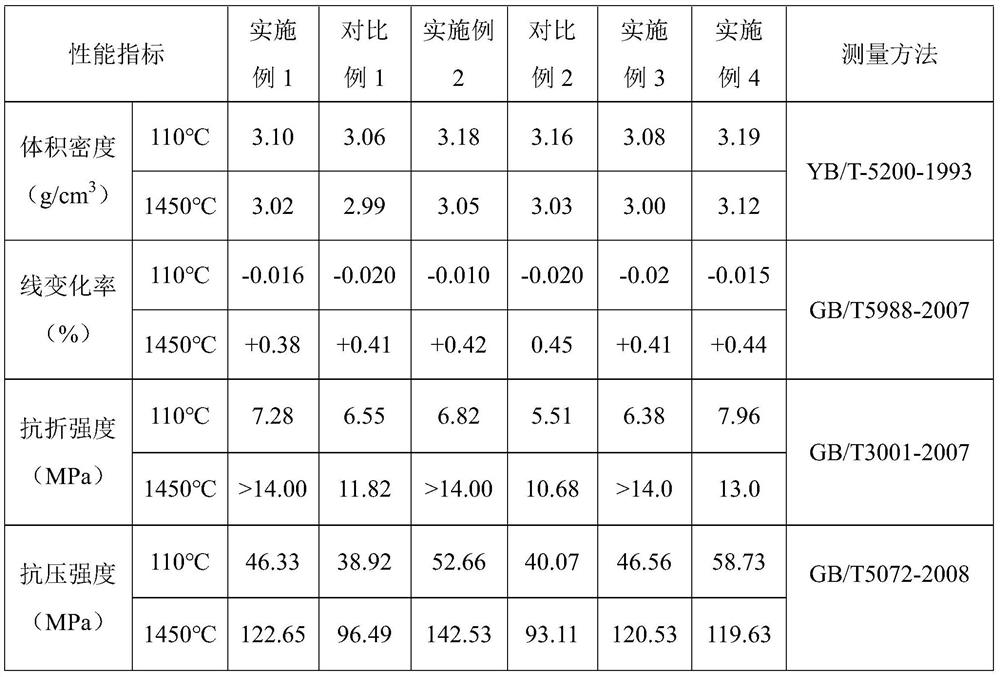

[0047] The technical solutions of the present invention are illustrated below through specific examples. It should be understood that one or more method steps mentioned in the present invention do not exclude that there are other method steps before and after the combined steps or other method steps can be inserted between these explicitly mentioned steps; it should also be understood that these The examples are only for illustrating the present invention and are not intended to limit the scope of the present invention. Moreover, unless otherwise stated, the numbering of each method step is only a convenient tool for identifying each method step, and is not intended to limit the sequence of each method step or limit the scope of the present invention. The change or adjustment of its relative relationship is in In the case of no substantive change in the technical content, it shall also be regarded as the applicable scope of the present invention.

[0048] In following embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com