A circulating denitrification device for food industry wastewater

A technology for industrial wastewater and denitrification, which is applied in the fields of food industry wastewater treatment, water pollutants, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

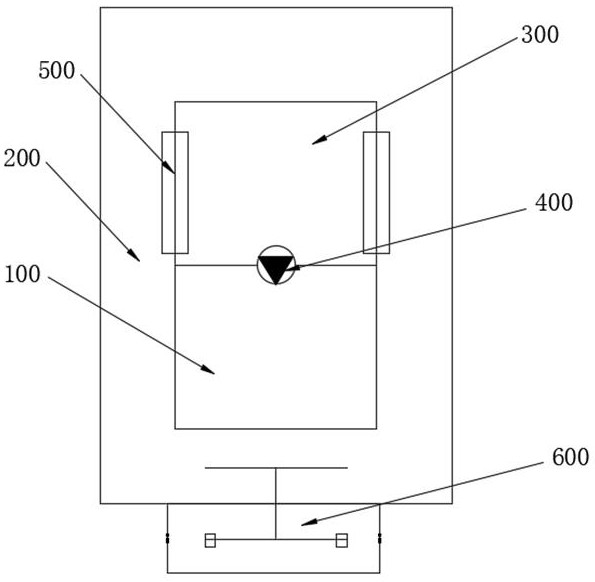

[0048] Such as figure 1 As shown, the present embodiment provides a kind of circulation denitrification system for food industry wastewater, including

[0049] An aerobic pool 100, the aerobic pool 100 provides an oxygen-enriched environment for the aerobic bacteria, and the aerobic bacteria convert nitrogen into nitrate in the aerobic pool 100;

[0050] Deoxygenation tank 200, said deoxygenation tank 200 is an open structure and communicates with the aerobic tank 100, for receiving the reactant in the aerobic tank 100 and reducing the solubility of oxygen in the reactant;

[0051] Anoxic pool 300, said anoxic pool 300 communicates with deoxygenated pool 200 and aerobic pool 100 respectively, is used to receive the reactant in deoxygenated pool 200, and anaerobic bacteria will nitrate in said anoxic pool 300 Reduce to nitrogen, and discharge the reactants in the anoxic pool 300 into the aerobic pool 100;

[0052] A pressurizing part 400, the pressurizing part 400 is arranged...

Embodiment 2

[0060] Such as figure 2 As shown, this embodiment provides a kind of circulation denitrification device for food industry wastewater, including

[0061] The first casing 1, the first casing 1 includes a first cavity 2 with an open top, and the first casing 1 is respectively connected with a feed inlet 3 and an outlet connected to the first cavity 2. Feed port 4;

[0062]The second casing 5, the second casing 5 is arranged in the first casing 1, the second casing 5 includes a separated second cavity 8 and a third cavity 9, the second casing The body 5 also includes a first side wall 6 and a second side wall 7, and the first side wall 6 wraps a second cavity 8; the second cavity 8 is located above the third cavity 9 and the second cavity The top of 8 communicates with the first cavity 2, and a pressurizing pump 10 is provided between the second cavity 8 and the third cavity 9 to pump the reactant to the third cavity 9; the second side wall 7 wrapping the first side wall 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com