A preparation method based on alkali-activated porous carbonized wood chips accumulation bed material and its application in solar desalination seawater

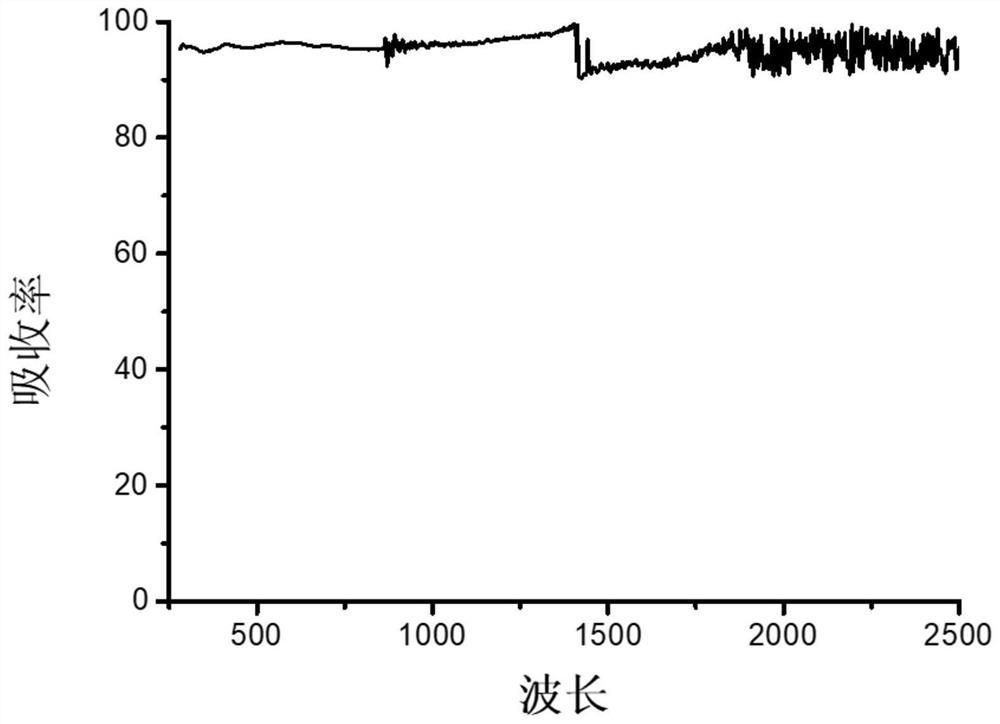

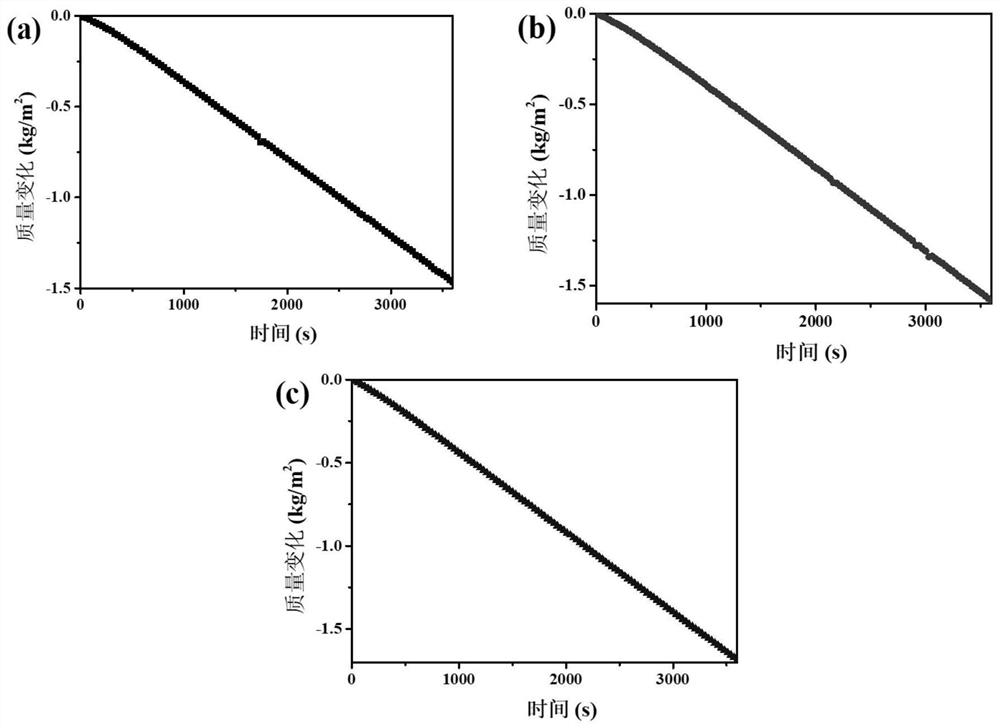

A technology of stacked bed and alkali activation, applied in chemical instruments and methods, seawater treatment, carbon compounds, etc., can solve the problems of high cost, complex manufacturing process, high price, etc., achieve strong hydrophilicity, reduce production cost, and achieve high efficiency. The effect of solar absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

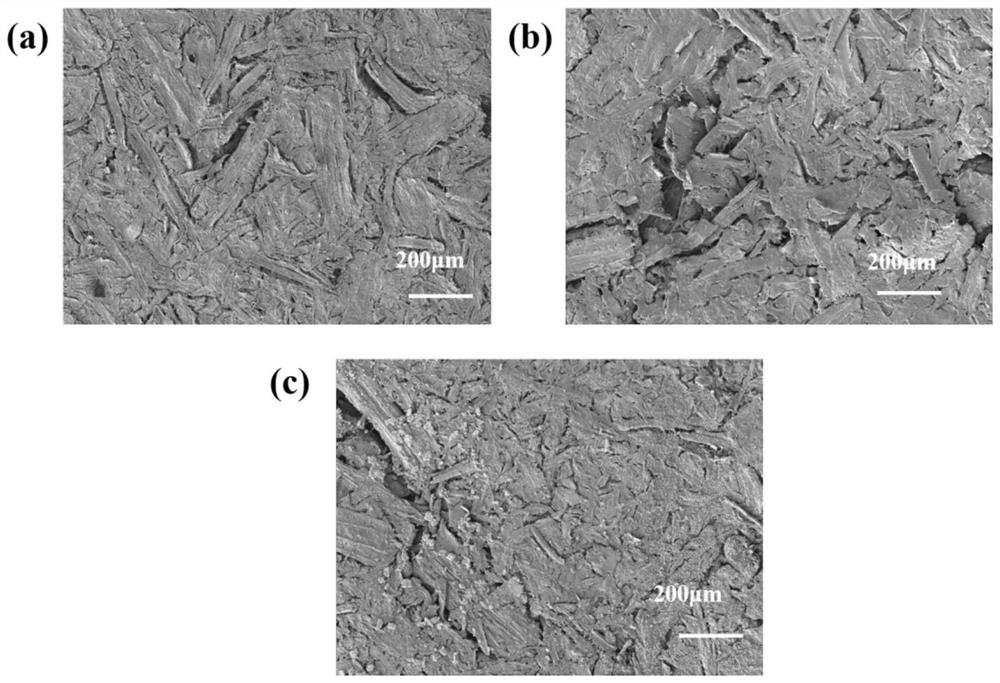

[0035] A preparation method based on alkali-activated porous carbonized wood chips accumulation bed material, comprising the following steps:

[0036] (1) Collect wood chips produced by processing wood, and obtain wood chips with a particle size of about 100 μm through screening treatment;

[0037] (2) Weigh about 4g of wood chips, put the wood chips into the cold pressing mold; press the wood chips to form by the pressure of 40MPa, and the holding time is 150s;

[0038] (3) placing the wood chip accumulation bed obtained in step (2) in a tube furnace, sintering for 25min under the condition of a vacuum environment and a temperature of 180°C, and the temperature rise rate of the tube furnace is 8°C / min to obtain bonding a bed of sawdust accumulation;

[0039] (4) The bonded wood chips piled bed obtained in step (3) was placed in a KOH ethanol solution of 0.04 g / mL and soaked for 12 minutes, filtered, and then the excess KOH was washed with ethanol and deionized water respecti...

Embodiment 2

[0042] A preparation method based on alkali-activated porous carbonized wood chips accumulation bed material, comprising the following steps:

[0043] (1) Collect wood chips produced by processing wood, and obtain wood chips with a particle size of about 100 μm through screening treatment;

[0044] (2) Weigh about 4g of wood chips, put the wood chips into the cold pressing mold; press the wood chips to form by the pressure of 40MPa, and the holding time is 100s;

[0045] (3) placing the sawdust stacking bed obtained in step (2) in a tube furnace, sintering for 15 minutes in a vacuum environment at a temperature of 250 °C, and the temperature rise rate of the tube furnace is 5 °C / min, to obtain bonding a bed of sawdust accumulation;

[0046] (4) The bonded wood chips piled bed obtained in step (3) was placed in a 0.1 g / ml KOH ethanol solution to soak for 6 minutes, filtered, and then the excess KOH was washed with ethanol and deionized water respectively, and placed in vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com