Lifting device used for building prefabricated slabs

A hoisting device and prefabricated board technology, which is applied in the direction of lifting equipment braking device, hoisting device, transportation and packaging, etc., can solve the problems of easy cracking of building materials, poor earthquake resistance, complex structure of advanced shock absorption equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

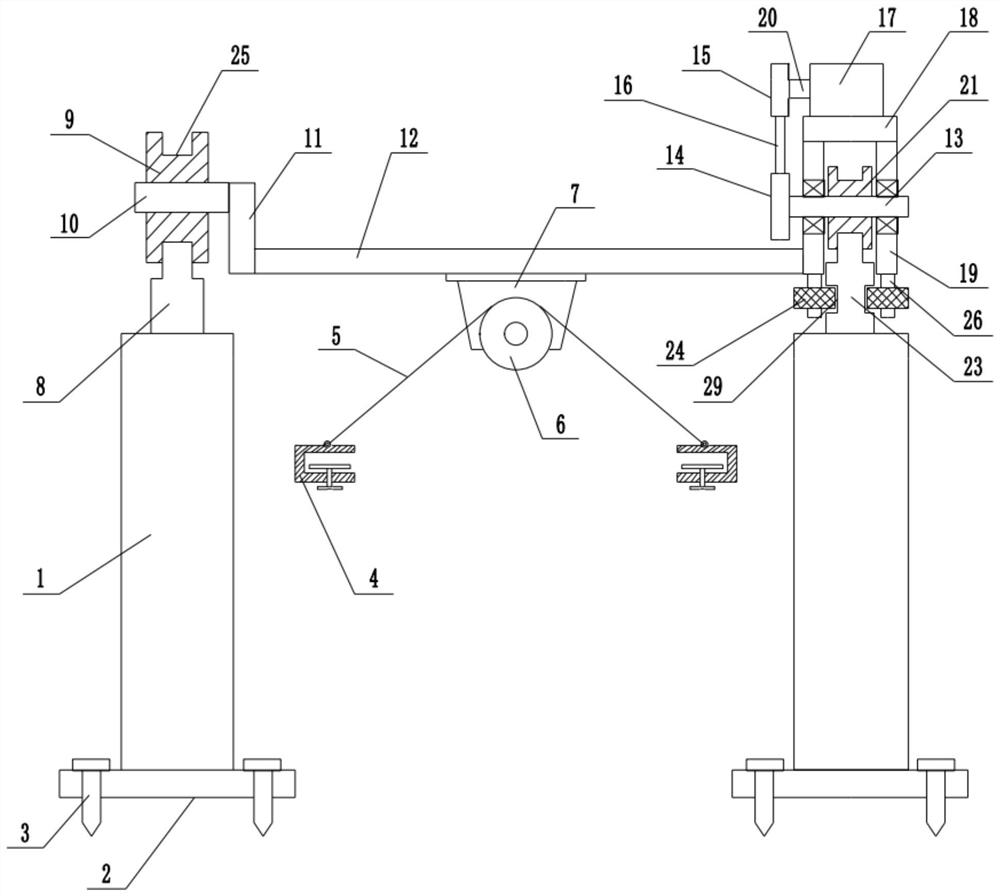

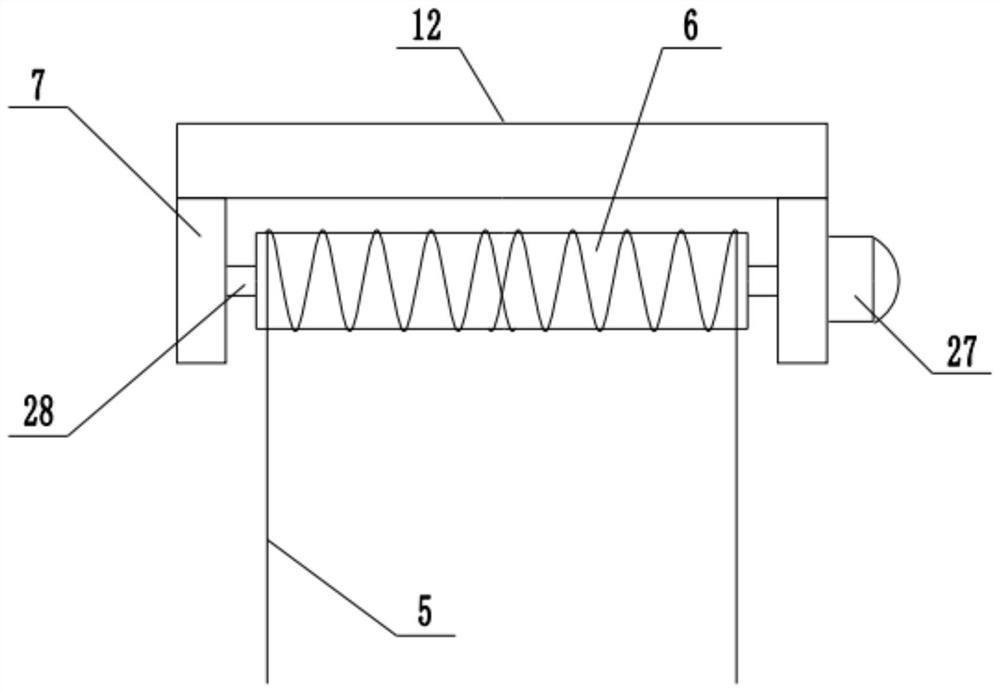

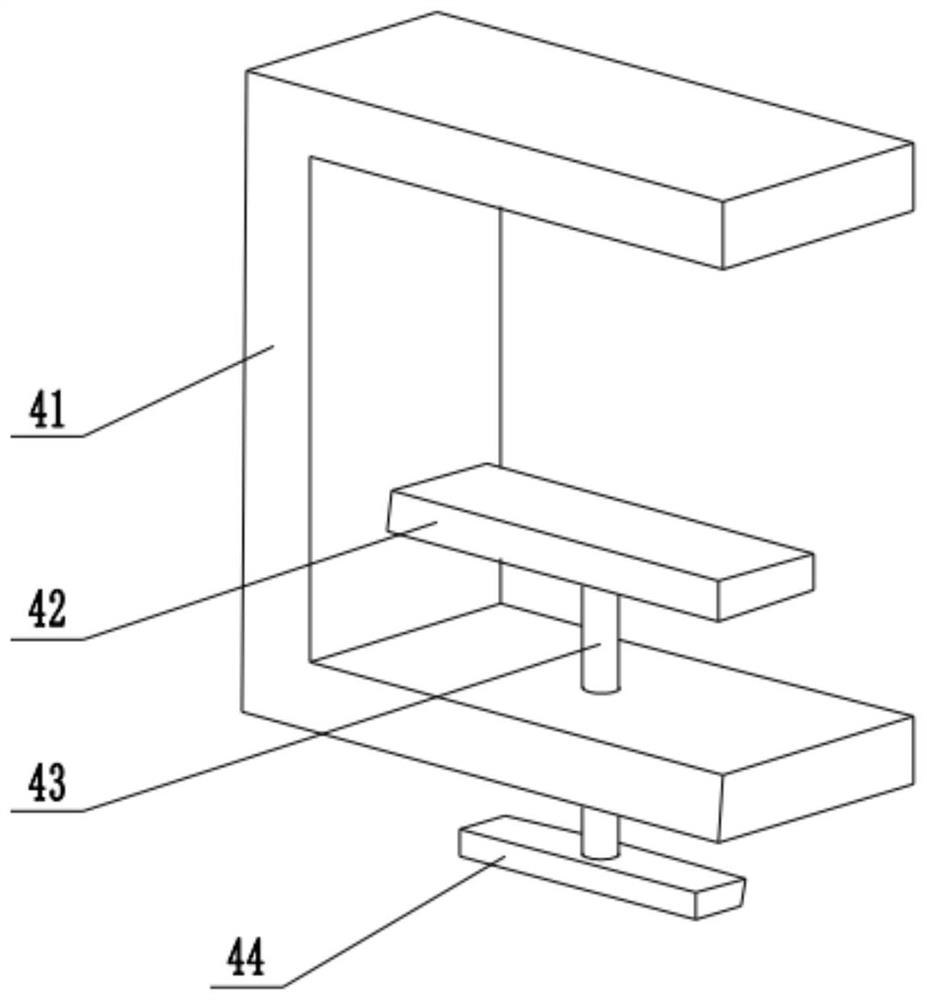

[0028] refer to Figure 1~3 , in an embodiment of the present invention, a lifting device for building prefabricated panels includes a fixed base plate 2, and fixing bolts 3 are installed on both sides of the lower end of the fixed base plate 2 to realize the fixed installation of the entire fixed base plate 2, and the fixed base plate 2 The upper end of the fixed column 1 is installed, and the left rail 8 is installed on the upper end of the left fixed column 1. The upper end of the left rail 8 is rotated and provided with a left roller 9. The left roller 9 is installed with a guide column 10 through a bearing, and the middle of the left roller 9 is rotated. There is a guide column 10, and a right rail 23 is installed on the upper end of the right fixed column 1, and a balance groove 29 cooperating with a balance wheel 24 is provided on both sides of the right rail 23, and is used to limit and guide the forward and backward movement of the walking frame 19. Avoid left and rig...

Embodiment 2

[0030]In another embodiment of the present invention, a fixed base plate 2 is included, fixing bolts 3 are installed on both sides of the lower end of the fixed base plate 2, a fixed column 1 is installed on the upper end of the fixed base plate 2, and a left rail 8 is installed on the upper end of the left fixed column 1. 8. The upper end of the left roller 9 is rotated to be provided with a left roller 9, and the guide column 10 is mounted on the left roller 9 through a bearing, and the middle part of the left roller 9 is rotated to be provided with a guide column 10. 23 both sides are provided with the balance groove 29 that cooperates mutually with balance wheel 24, and the upper end of right track 23 is rotated and is provided with right roller 21, and the middle part of right roller 21 is fixedly installed with rotating shaft 13, and the two ends of rotating shaft 13 are installed walking frame through bearing 19. The balance column 26 is installed at the bottom of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com