Flexibly packaged battery cell module-free battery unit and processing technology

A modular battery and cell technology, applied in the direction of batteries, electrical components, secondary batteries, etc., can solve the problems of high cost, low system volume utilization, heavy weight, etc., to save mold costs, reduce weight, weight Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

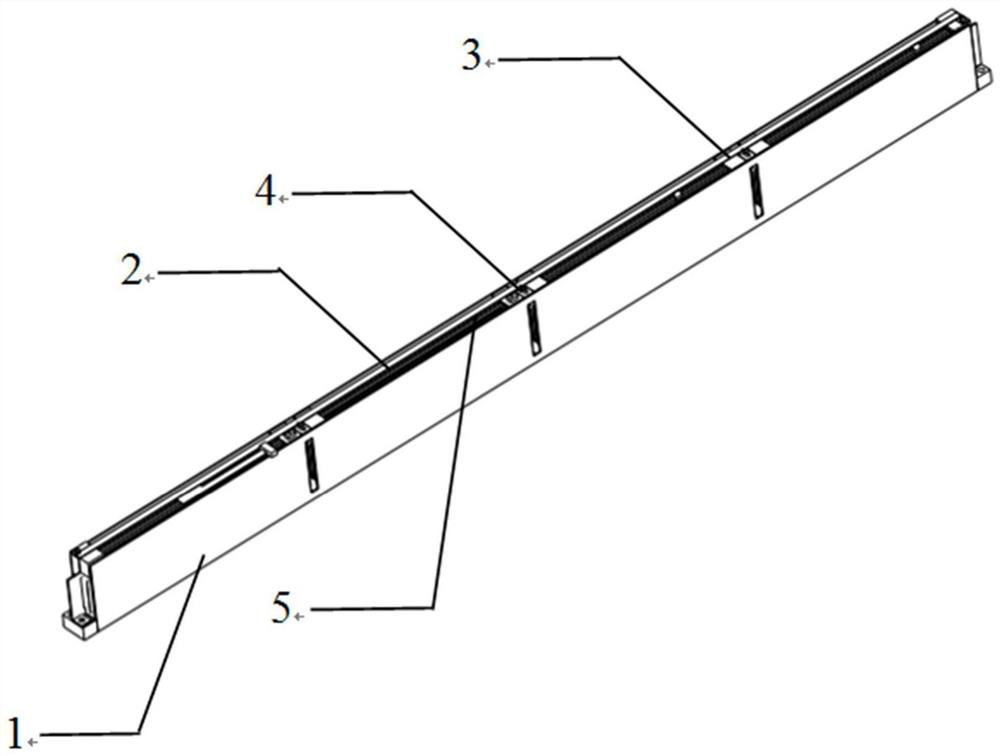

[0021] A soft-packed battery cell moduleless battery unit, including a long aluminum frame 1, a number of stacked cells 2 are evenly distributed in the aluminum frame 1, and a flexible circuit board 5 (FPC) is connected to the stacked cells 2 ; A cell limiting block 3 is arranged between adjacent stacked cells 2 , and a unit insulating block 4 is arranged in the middle of the cell limiting block 3 .

[0022] A processing technology for a soft-pack battery cell without a module, comprising the following steps:

[0023] Step 1: Aluminum extrusions form a suitable aluminum frame 1;

[0024] Step 2: Glue the soft-packed cells and cushioning materials together and stack them into blocks to make stacked cells 2;

[0025] Step 3: Insert the stacked cell 2 into the aluminum frame 1 by the manipulator;

[0026] Step 4: Weld the cell limit block 3 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com