Silicon/silicon oxide/carbon composite negative electrode material for lithium ion battery and preparation method of silicon/silicon oxide/carbon composite negative electrode material

A lithium-ion battery, silicon oxide technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve problems such as agglomeration, incomplete layer structure, poor stability, etc., and achieve reduced volume expansion. , The effect of less capacity loss and maintaining structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the silicon / silicon oxide / carbon composite negative electrode material for the lithium ion battery, the silicon / silicon oxide / carbon composite negative electrode material for the lithium ion battery, comprises the following steps:

[0046] S1. Preparation of nano-silicon particles: preparing nano-silicon ions with a size of 20-300 nm;

[0047] S2. Nano Si@SiO x Preparation of core-shell structure materials:

[0048] In-situ oxidation treatment of the prepared nano-silicon powder in an oxidizing agent to prepare Si@SiO with controllable thickness x Core-shell structure material, SiO x The thickness of the shell layer is controllable, and the size can be 1-50nm;

[0049] S3. Purification treatment:

[0050] Si@SiO prepared above x The core-shell structure material is treated with acidification to remove soluble metal ions, and then washed with pure water for at least 3 times before use;

[0051] S4. Mixing and dispersing:

[0052] The puri...

Embodiment 1

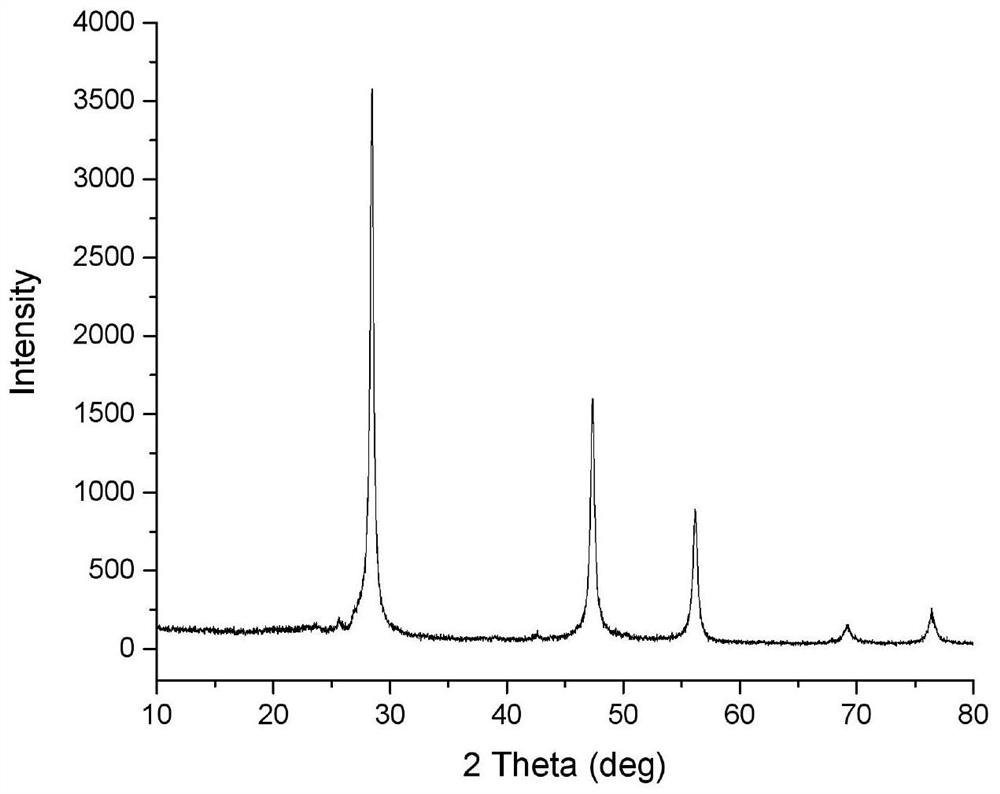

[0071] S1. Preparation of nano-silicon particles

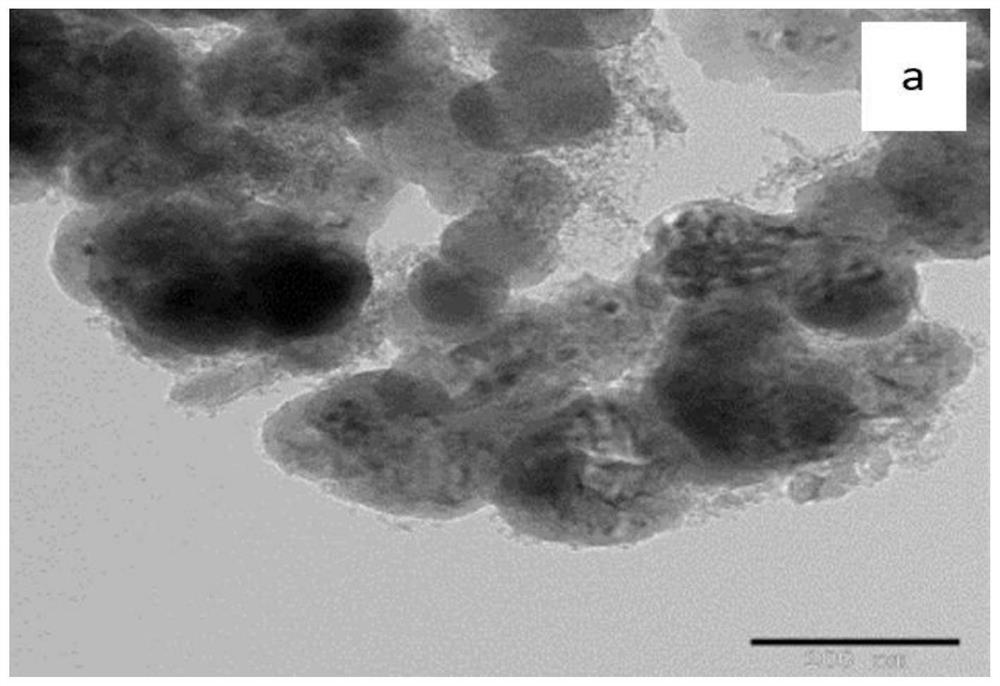

[0072] Using QM-3SP04 planetary ball mill, zirconia balls as the ball milling medium, micron-sized silicon powder as the raw material, ball-material ratio of 20:1, ball milling at 500r / min for 12 hours to obtain spherical nano-silica powder, silicon powder particles The size is 100nm.

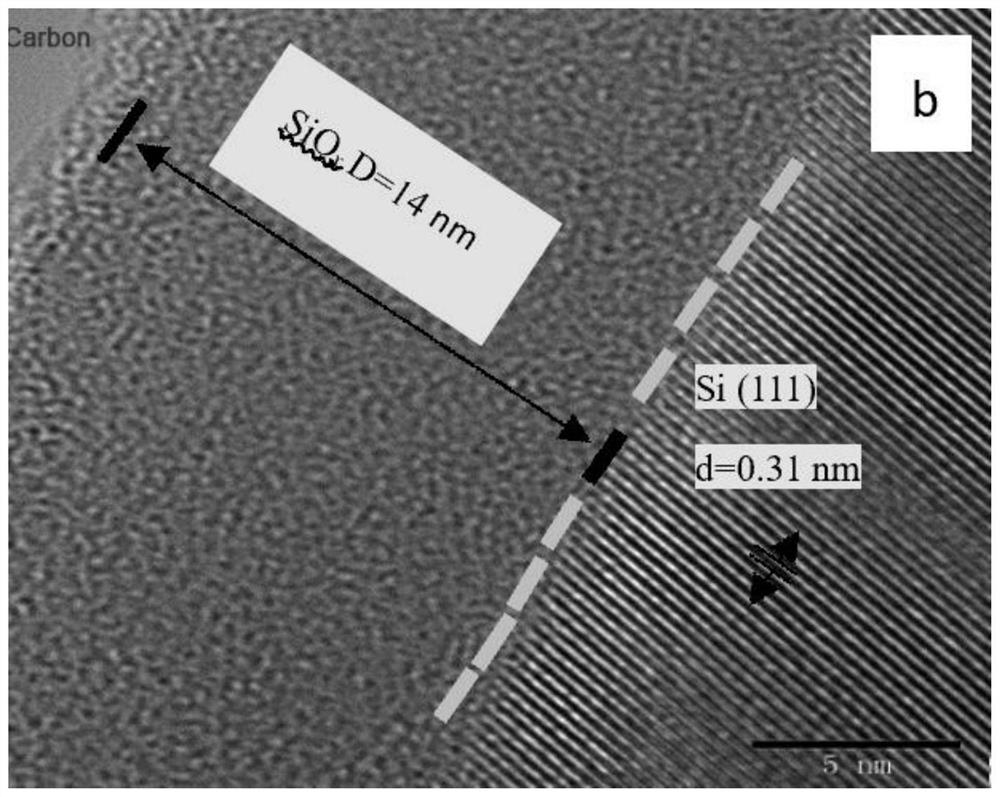

[0073] S2. Nano Si@SiO x Preparation of core-shell structure materials

[0074] Treat the above-prepared nano-silicon powder in an oxygen atmosphere at 500 °C for 3 h to prepare Si@SiO with a silicon oxide inner layer thickness of 14 nm x Core-shell structural materials.

[0075] S3. Purification treatment

[0076] Si@SiO prepared above x The core-shell structure material was acidified with 1 mol / L hydrochloric acid for 1 h to remove soluble metal ions, and then washed with pure water for 3 times.

[0077] S4. Mixing and dispersing

[0078] The purified Si@SiO x The core-shell structure material and sucrose are ultrasonically pre-disper...

Embodiment 2

[0090] S1. Preparation of nano-silicon particles

[0091] Using QM-3SP04 planetary ball mill, using zirconia balls as the ball milling medium, micron-sized silicon powder as the raw material, the ratio of ball to material is 20:1, and the solution of ethanol and water (volume ratio 50:50) at 300r / min The slurry of nano-silicon powder was prepared by ball milling for 24 hours, and the particle size of the silicon was 300 nm.

[0092] S2. Nano Si@SiO x Preparation of core-shell structure materials

[0093] Treat the prepared nano-silicon powder with 0.5mol / L potassium permanganate solution for 0.5h to prepare Si@SiO with a thickness of 2nm x Core-shell structural materials.

[0094] S3. Purification treatment

[0095] Si@SiO prepared above x The core-shell structure material was treated with 2mol / L acetic acid solution to remove soluble metal ions, and then washed with pure water for 4 times.

[0096] S4. Mixing and dispersing

[0097] The purified Si@SiO x The core-shel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com