Electric heating fluidized bed heat accumulator and heat supply system

A heating system and fluidized bed technology, used in heating systems and central heating, can solve the problems of complex heat exchange structure of solid particles, low service life of heat exchangers, uneven solid heat storage, etc., and improve energy utilization. Efficiency, saving electricity, solving the effect of uneven heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

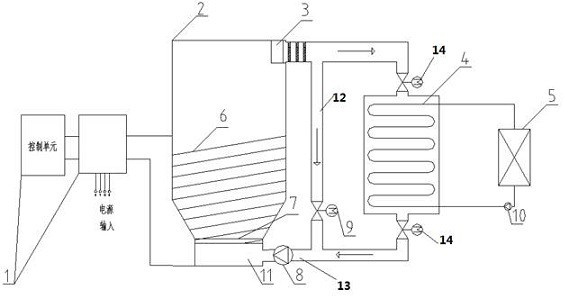

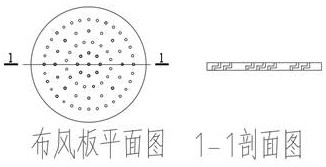

[0027] figure 1 An electrically heated fluidized bed solid heat storage and heat supply system is shown. like figure 1 As shown, an electrically heated fluidized bed solid heat storage and heat supply system includes a fluidized bed heat accumulator 2, a heat exchanger 4, a heat user 5, an electromagnetic heating coil 6, and a controller 1. Solid heat storage particles are set as the heat storage working medium, and the outside of the fluidized bed heat accumulator 2 is wound with an electromagnetic heating coil 6, which is used to release heat to the solid heat storage particles and heat the air passing through the solid particles. The heating coil 6 is connected to the controller 1, and the air inlet chamber 11 is arranged under the fluidized bed regenerator 2, and the air inlet chamber 11 is connected to a return air pipe, and a frequency conversion fan 8 is arranged on the return air pipe, and the fluidized bed heat storage The upper part of the device 2 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com