Preparation method of coalescing agent, coalescing agent and coating containing coalescing agent

A film-forming aid and coating technology, applied in the coating field, can solve the problems of non-renewable resources, high volatility, environmental pollution, etc., and achieve the effects of shortened reaction time, less by-products, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of film-forming aid, comprising the following steps:

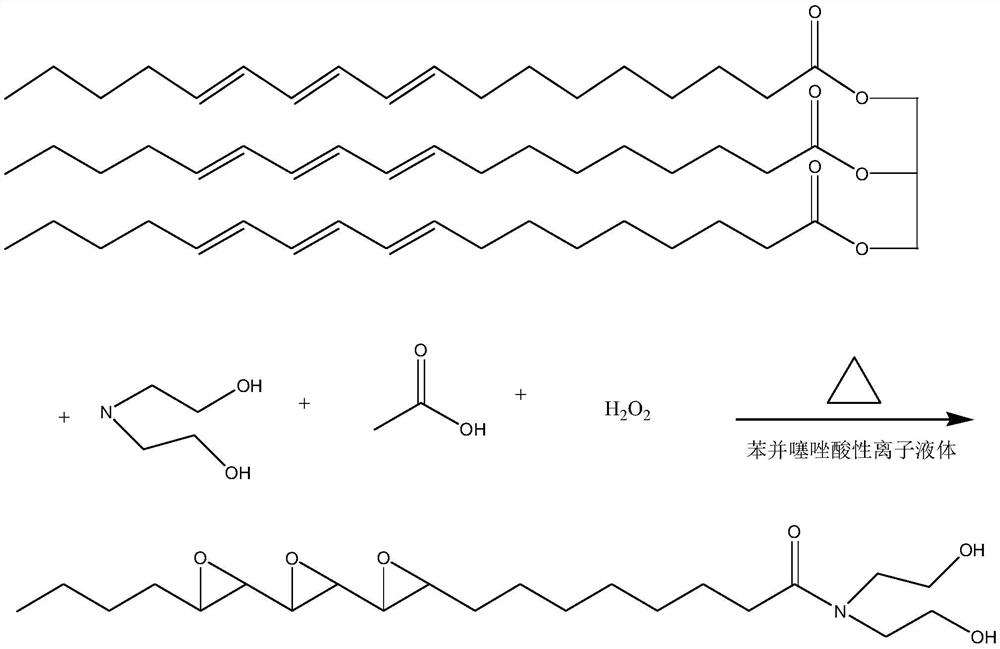

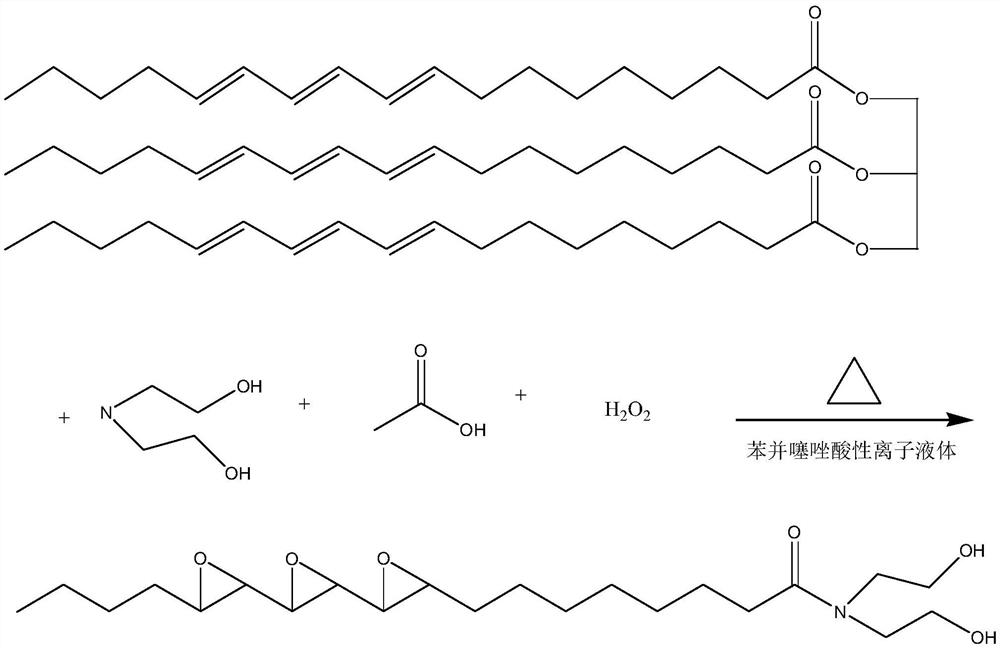

[0025] Add tung oil, diethanolamine, benzothiazole acidic ionic liquid catalyst, acetic acid and petroleum ether into the container, slowly heat up to 50-90°C to obtain a mixed solution, and drop hydrogen peroxide into the mixed solution within 1-5 hours solution, and then keep it warm for 1-15 hours. After the reaction, cool to room temperature and filter. The filter cake is an ionic liquid liquid. The lower water layer is removed, the oil layer is dried, and the solvent is removed to obtain epoxy ligoleoyl diethanolamine, which is the film-forming aid, and the reaction formula is as follows:

[0026]

[0027] The mol ratio of described tung oil, diethanolamine, acetic acid and hydrogen peroxide solution is: n (tung oil): n (diethanolamine): n (acetic acid): n (hydrogen peroxide solution): n (petroleum ether)=1: (3~6):(6~9):(6~12):(2~4).

[0028] The benzothiazole acidic ionic liquid catal...

Embodiment 1

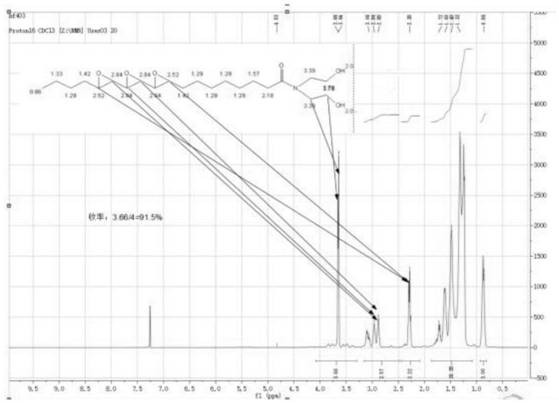

[0037] The preparation method of the film-forming aid of the present embodiment comprises the following steps: adding tung oil, diethanolamine, acetic acid and petroleum ether into a mixture equipped with electric stirring, a thermometer, and a dropping funnel according to a molar ratio of 1:3.6:6.6:3. and the four-necked reaction flask of the condensing pipe, then add the benzothiazole phosphate liquid catalyst, the weight of the benzothiazole phosphate liquid catalyst is 0.5% of the weight of tung oil, put the reaction flask in a constant temperature water bath, stir at room temperature, slowly Heat up to 65°C to obtain a mixed solution, then add dropwise a hydrogen peroxide solution with a mass fraction of 30% to the mixed solution while stirring, wherein the molar ratio of the hydrogen peroxide solution to tung oil is 10.2:1, and then keep warm 10h, after the reaction is over, cool to room temperature, at this time, benzothiazole phosphate condenses into a solid, filter to ...

Embodiment 2

[0040]The preparation method of the film-forming aid of the present embodiment comprises the following steps: adding tung oil, diethanolamine, acetic acid and petroleum ether into a mixture equipped with electric stirring, a thermometer and a dropping funnel according to the molar ratio of 1:4.0:6.6:3. and the four-necked reaction flask of the condensing tube, then add the benzothiazole phosphate catalyst, the weight of the benzothiazole phosphate is 0.3% of the weight of tung oil, put the reaction flask in a constant temperature water bath, and after stirring at room temperature, slowly heat up to to 90°C to obtain a mixed solution, and then dropwise add a hydrogen peroxide solution with a mass fraction of 30% to the mixed solution while stirring, wherein the molar ratio of the hydrogen peroxide solution to tung oil is 8:1, and then keep warm for 12h, and react After finishing, cool to room temperature, at this moment, benzothiazole phosphate condenses into solid, remove benzo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com