Multi-physical field enhanced high-electrolyte wastewater treatment method and multi-physical field enhanced high-electrolyte wastewater treatment device

A wastewater treatment, multi-physics technology, applied in natural water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low desalination efficiency, incomplete desalination, secondary pollution, etc., and achieve simple operation. , The conditions are simple, and the effect of preventing waste water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

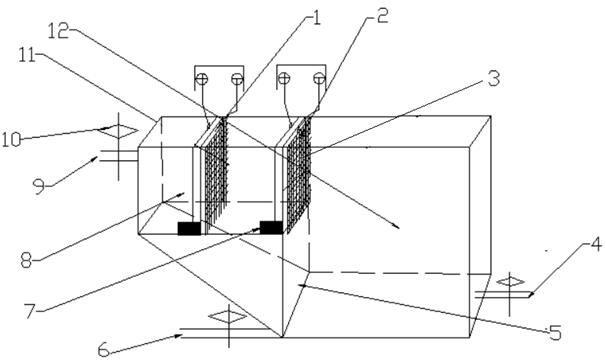

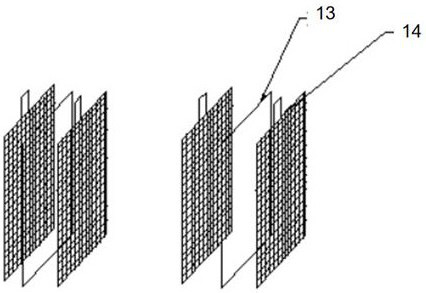

[0035]Example 1: The salt content of a synthetic pharmaceutical wastewater is 35% of TDS content.figure 1 The shown multi-physical field enhanced high electrolyte wastewater treatment device completes the purification treatment of the synthetic pharmaceutical wastewater. The device includes an anion filter assembly 1, a cation filter assembly 2, a water outlet Ⅱ 3, a water outlet Ⅰ 4, a partition 5, and a salt discharge port 6. , Ultrasonic generator 7, inlet pool 8, water inlet 9, shell 11, outlet pool 12, the anion filter assembly is composed of two conductive screens sandwiching an anion selective permeation membrane, the anion filter assembly is on the water inlet side The conductive screen is connected to the positive pole of the power supply, and the conductive screen on the outlet side is connected to the negative pole of the power supply; the cation filter assembly is composed of two conductive screens 14 sandwiching a cation selective permeation membrane 13, and the conduct...

Embodiment 2

[0041]Example 2: The salt content of a high-salinity wastewater is 45% TDS.figure 1 The shown multi-physics enhanced high-electrolyte wastewater treatment device completes the purification treatment of high-salinity wastewater. The structure of the device is the same as that of Example 1, except that it is equipped with 2 anion filter components, 2 cation filter components, anion filter components and cations The filter components are arranged alternately at intervals, with an interval of 5 cm, and the mesh size of the conductive mesh screen is 300 mesh; the cation selective permeation membrane is a CMX membrane, and the anion membrane is an ACM membrane.

[0042]The specific method of salt separation in the above-mentioned synthetic pharmaceutical wastewater is as follows:

[0043](1) Install the filter module and check whether the combination of the filter module and the reactor side wall is airtight;

[0044](2) Pour the high-electrolyte wastewater into the pool at a flow rate of 1.2m / s, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com