Ball-billet demolding device and powder forming machine

A technology of demoulding device and ball socket, which is applied in the direction of ceramic molding machine, unloading device, mold, etc., can solve the problems of ball blank breaking, ball blank is not easy to come out from the ball socket, etc., and achieve the reduction of scrap rate, simple structure, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

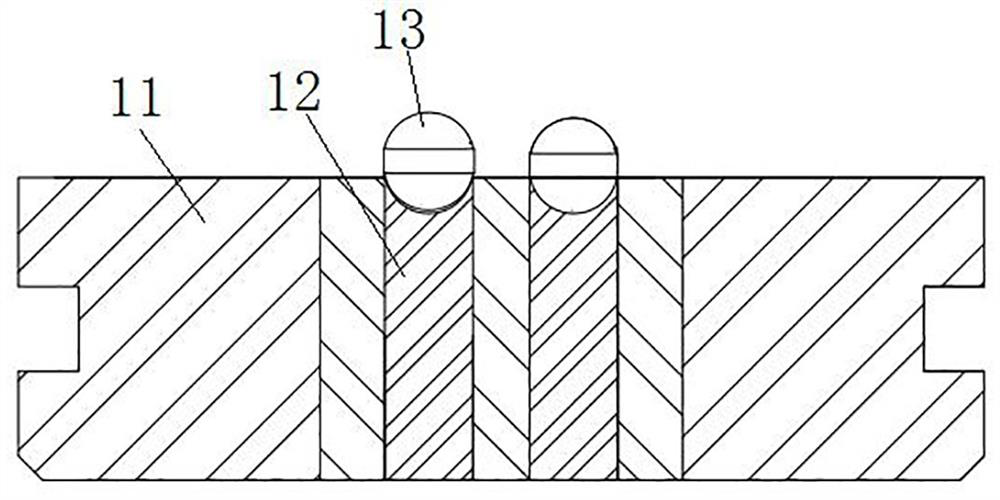

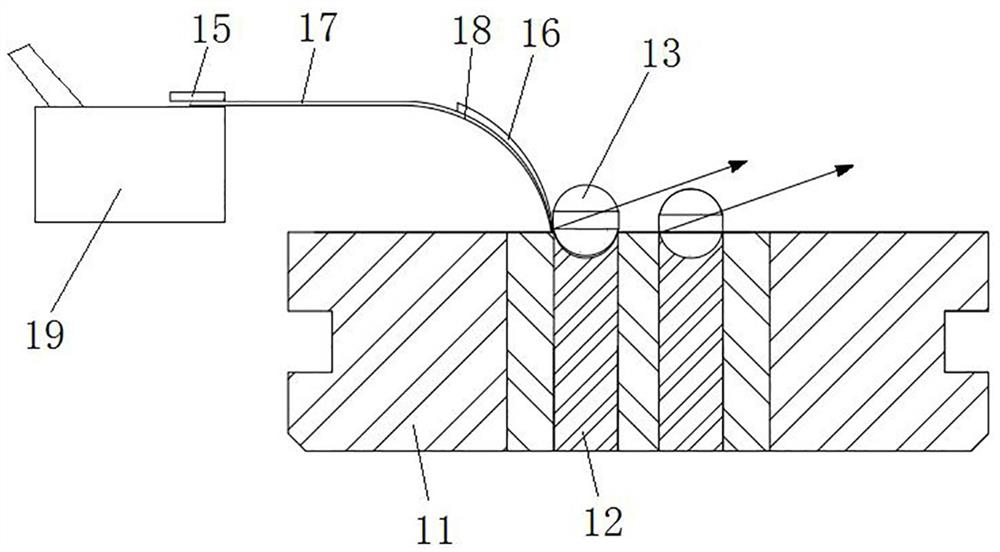

[0053] Such as figure 2As shown, the powder molding machine includes a molding die 11, a lower punch 12 and an upper punch (not shown), and the opposite ends of the upper punch and the lower punch 12 are provided with ball sockets, and the upper punch and the lower punch 12 During the relative movement in the up and down direction, the powdery material in the mold cavity of the forming die 11 is squeezed to form the billet 13, and then the upper punch moves upward, and the lower punch 12 moves upward relative to the forming die 11 to demoulding. Location.

[0054] In this embodiment, a material shoe 19 is provided on the side of the forming mold 11, and the material shoe 19 reciprocates along the horizontal direction to send the powdery material into the mold cavity of the forming mold 11, wherein the material shoe 19 is an existing mature product , which will not be repeated here.

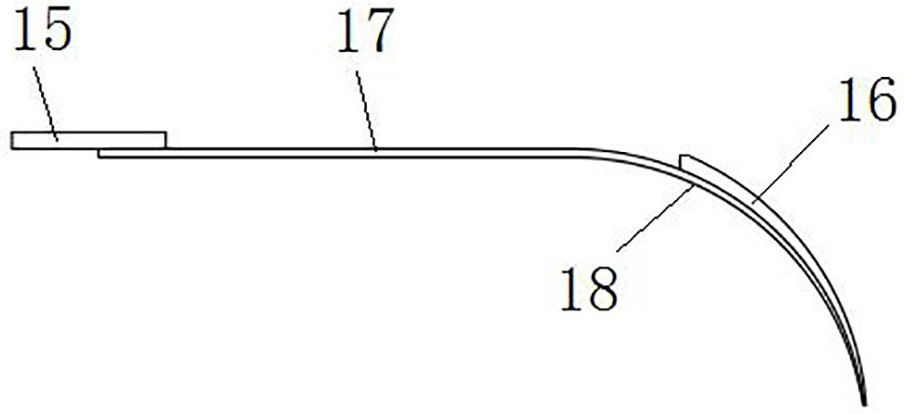

[0055] In this embodiment, a ball blank demoulding device is provided on the material shoe ...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the horizontal section 17 is bonded and fixed on the upper surface of the shoe 19 through the foam 15, so that the horizontal section 17 has a certain movable margin in the up and down direction. In this embodiment, the horizontal section is glued and fixed on the upper surface of the material shoe through a rubber pad, so that the horizontal section has a certain movable margin in the up and down direction, wherein the lower side of the rubber pad is coated with glue.

Embodiment 3

[0068] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the horizontal section 17 is fixed on the upper surface of the material shoe 19 by bonding the foam 15 . In this embodiment, a slot is provided on the side of the material shoe facing the billet, and the horizontal section is inserted into the slot to achieve fixation, wherein the width of the slot in the up and down direction is slightly larger than the thickness of the horizontal section, so that the horizontal section The segment has a certain margin of activity in the up and down direction, so that the plectrum has a certain margin in the up and down direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com