Low-temperature flue gas efficient desulfurization, denitrification and white smoke removal integrated equipment

A technology for desulfurization, denitrification, and low-temperature flue gas, which is applied in gas treatment, lighting and heating equipment, and air quality improvement. , the effect of high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

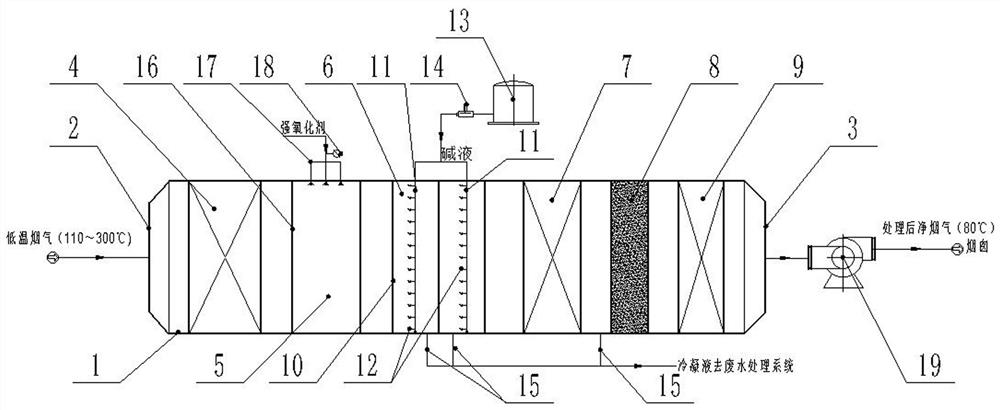

[0026] Furthermore, as a specific embodiment of the low-temperature flue gas high-efficiency desulfurization, denitrification and dewhitening integrated equipment described in the present invention, the high-pressure atomization spray device 6 includes a spray chamber 10, and the spray chamber 10 is provided with at least A set of spray pipeline assemblies 11 distributed along the height direction of the spray chamber 10. The spray pipeline assemblies 11 are connected with multi-layer staggered arrangement of atomizing nozzles 12. In a specific embodiment, the pressure of the atomizing nozzles 12 is 10MPa, the spray pipeline is connected to the alkali liquid storage tank 13 located outside the equipment housing 1 through a high-pressure atomizing pump 14, and the bottom of the spray chamber 10 is provided with a recovery pipeline 15 connected to an external wastewater treatment system. The spray pipeline assembly 11 is distributed along the height direction of the spray chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com