Low-alarm-rate high-purity turnout steel rail and preparation method thereof

A technology with high alarm rate and purity, applied in the field of low alarm rate and high purity turnout rail and its preparation, can solve the problems of low alarm rate and high purity, achieve low alarm rate, increase dispersion degree, and excellent contact fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

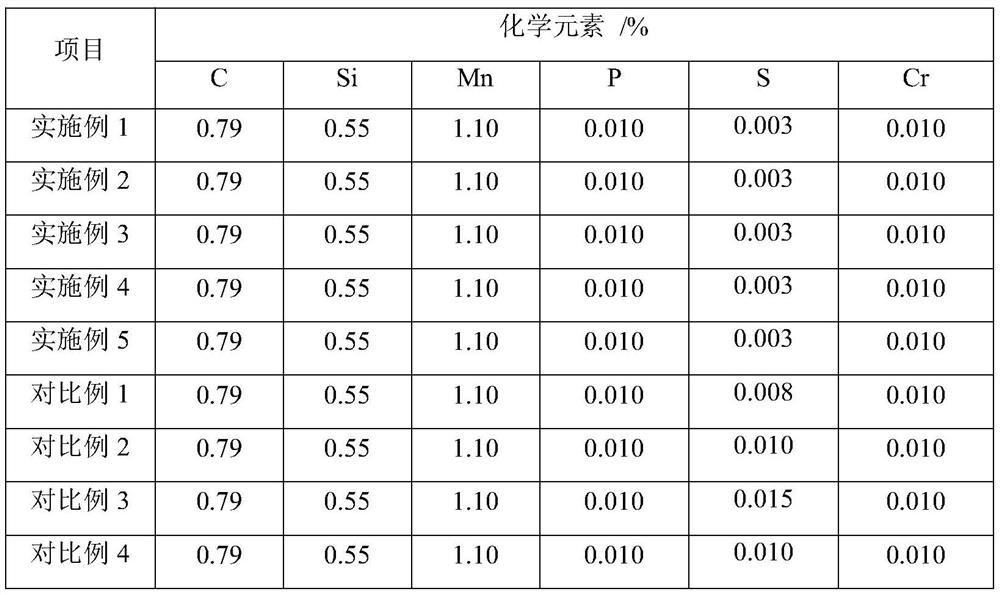

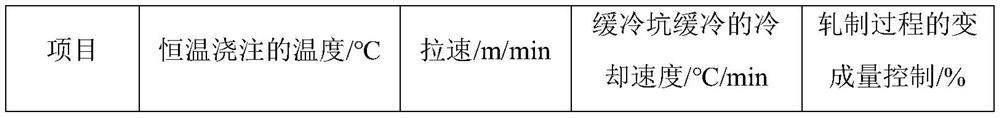

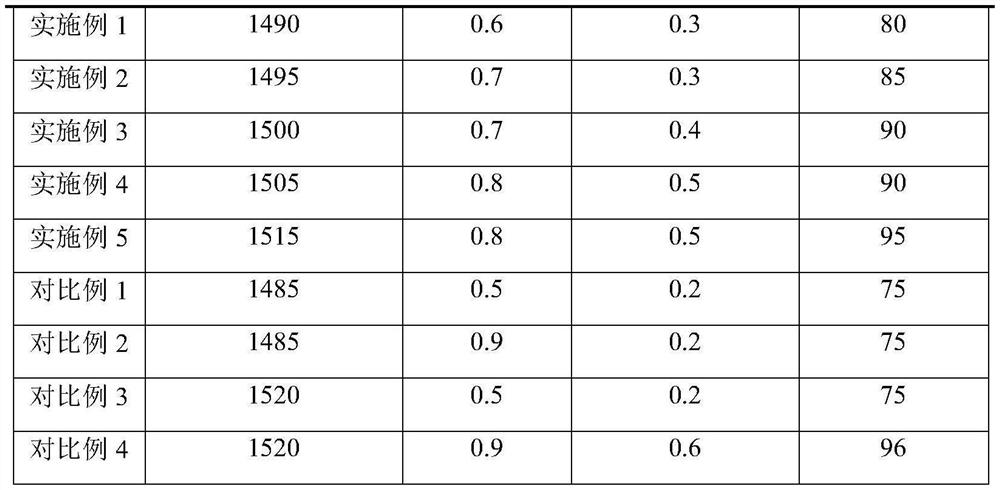

[0020] Specifically, the invention provides a method for preparing turnout rails with low alarm rate and high purity. The method comprises the following steps: using molten iron with an S content of 0.008-0.012% for converter smelting, and feeding calcium-sulfur ratio during the smelting process is 8.0×10 6 ~10.0×10 6 (length m / S% content) of the calcium wire, control the ratio of hydrogen content to sulfur content H (ppm) / S (wt%) <400, through a small platform, LF refining, RH vacuum treatment, the whole process of protection cast steel billet, The casting temperature is 1490-1515°C, and the casting speed is 0.6-0.8m / min. The cast billet enters the slow cooling pit for slow cooling, and the cooling speed is 0.3-0.5°C / min. The cooled billet is homogenized with austenite , the homogenization temperature is 1000℃~1300℃, and the time is 200~500min, fully complete the diffusion process of organization and texture, homogenize the organization, and fully diffuse the inclusions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com