A method for improving low-temperature mechanical properties of cast al-si alloy

An al-si, alloy technology, applied in the field of aluminum alloy, can solve the problem of low plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

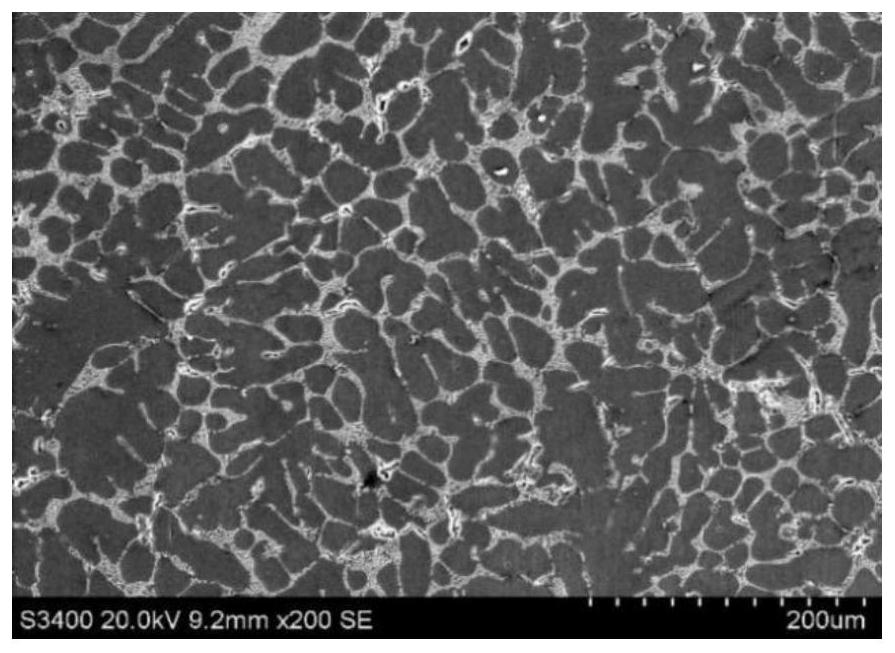

Image

Examples

Embodiment 1

[0038] Pure Al and Al-Si intermediate alloy was placed in a graphite crucible, and the graphite crucible was placed in the RGL-15-type well resistant furnace, and the temperature of the electric resistance furnace was set to 750 ° C, heat insulation to pure Al and Al The -si intermediate alloy is completely melted, and the pure Mg and Al-50FE intermediate alloy is pressed into the resulting melt system, and the incubation of 10 min, pure Mg and Al-50FE is completely melted to obtain the first melt, the first The melt components include: silicon 7.0% by weight, magnesium 0.30 wt%, iron 0.13 wt%, and margin is Al;

[0039] The first melt is lowered to 680 ° C, and the Al-SR intermediate alloy and the Al-10 RE intermediate alloy are added to the first melt, so that the SR is added to 0.3%, RE The addition amount is 0.2% of the first melt mass (the RE includes La and Ce, the molar ratio of the La and CE of 1: 2), plus insulation to Al-SR in the middle of Al-10RE The alloy is completel...

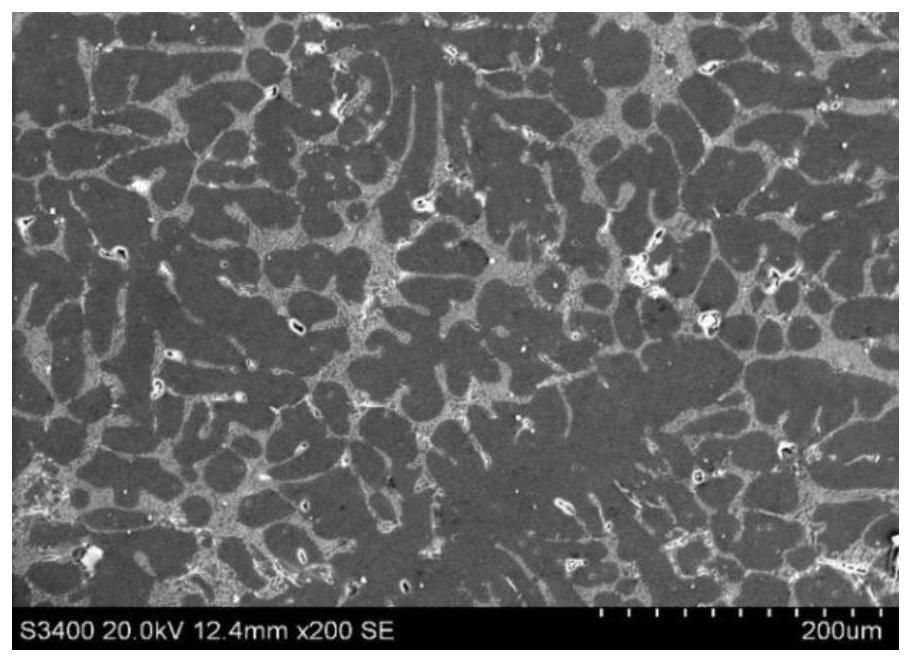

Embodiment 2

[0043] The Al-7Si-0.3 mg alloy was evolved in accordance with the method of Example 1, and the Al-7Si-0.3 mg alloy treatment treated was obtained, and the amount of RE added was 0.4% of the first melt mass.

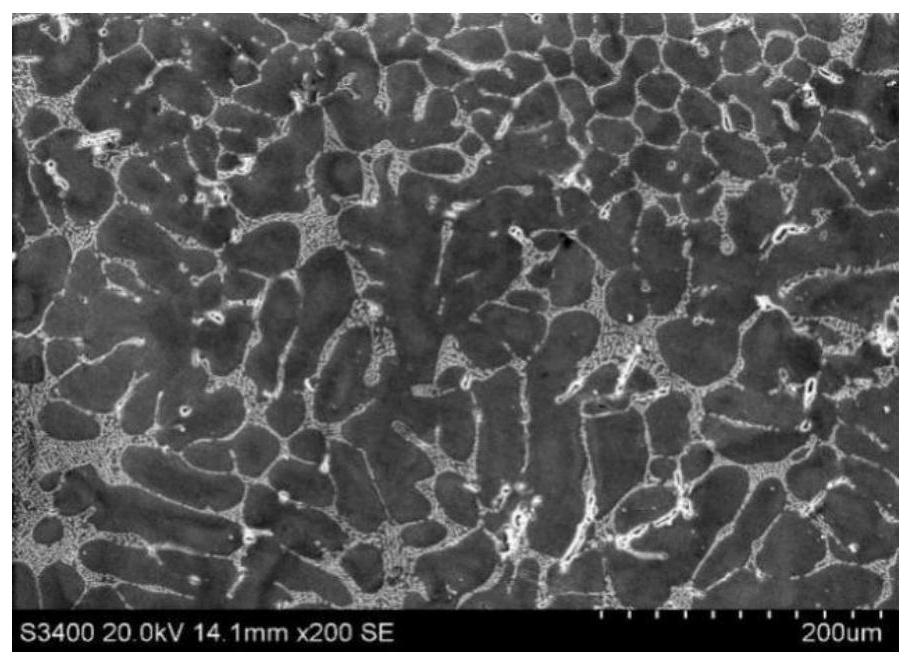

Embodiment 3

[0045] The Al-7Si-0.3 mg alloy was evolved in accordance with the method of Example 1 to obtain a deterioration of Al-7Si-0.3 mg alloys, and the amount of RE is 0.6% of the first melt mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com