Environment-friendly efficient heavy oil viscosity reducer

A heavy oil viscosity reducer, an environmentally friendly technology, applied in the field of heavy oil viscosity reducer, can solve the problems of environmental protection, high energy consumption, environmental pollution, etc., and achieve excellent hydrophilic and lipophilic performance, excellent viscosity reducing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An environment-friendly high-efficiency heavy oil viscosity reducer, including the first polymer and compound additives;

[0033] The environment-friendly high-efficiency heavy oil viscosity reducer is made by the following method:

[0034] The first polymer and compounding additive are uniformly mixed according to the weight ratio of 0.1:3 to prepare the environment-friendly high-efficiency heavy oil viscosity reducer.

[0035] The first polymer is made by the following method:

[0036] Step S1, adding octadecyl methacrylate to 10% sodium hydroxide aqueous solution by mass fraction and washing until colorless, then washing with deionized water until neutral, filtering, and drying at 60°C for 20 hours to obtain refined octadecyl methacrylate Esters; heat 95% ethanol in a water bath until boiling, then add azobisisobutyronitrile and stir at a constant speed until dissolved, suction filter, cool and crystallize to obtain refined azobisisobutyronitrile;

[0037] Step S2, a...

Embodiment 2

[0043] An environment-friendly high-efficiency heavy oil viscosity reducer, including the first polymer and compound additives;

[0044] The environment-friendly high-efficiency heavy oil viscosity reducer is made by the following method:

[0045] The first polymer and compounding additive are uniformly mixed according to the weight ratio of 0.2:3 to prepare the environment-friendly high-efficiency heavy oil viscosity reducer.

[0046] The first polymer is made by the following method:

[0047] Step S1, adding octadecyl methacrylate to 8% sodium hydroxide aqueous solution by mass fraction and washing until colorless, then washing with deionized water until neutral, filtering, and drying at 60°C for 20 hours to obtain refined octadecyl methacrylate Esters; heat 95% ethanol in a water bath until boiling, then add azobisisobutyronitrile and stir at a constant speed until dissolved, suction filter, cool and crystallize to obtain refined azobisisobutyronitrile;

[0048] Step S2, ...

Embodiment 3

[0054] An environment-friendly high-efficiency heavy oil viscosity reducer, including the first polymer and compound additives;

[0055] The environment-friendly high-efficiency heavy oil viscosity reducer is made by the following method:

[0056] The first polymer and compounding additive are uniformly mixed according to the weight ratio of 0.4:3 to prepare the environment-friendly high-efficiency heavy oil viscosity reducer.

[0057] The first polymer is made by the following method:

[0058] Step S1, adding octadecyl methacrylate to 10% sodium hydroxide aqueous solution by mass fraction and washing until colorless, then washing with deionized water until neutral, filtering, and drying at 60°C for 20 hours to obtain refined octadecyl methacrylate Esters; heat 95% ethanol in a water bath until boiling, then add azobisisobutyronitrile and stir at a constant speed until dissolved, suction filter, cool and crystallize to obtain refined azobisisobutyronitrile;

[0059] Step S2,...

PUM

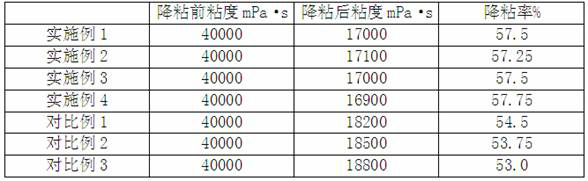

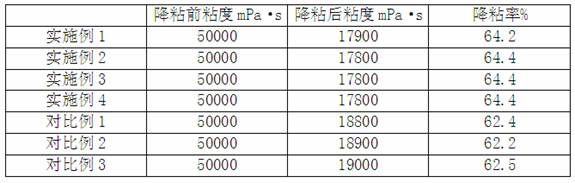

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com