Process for recycling wastes in sewage treatment

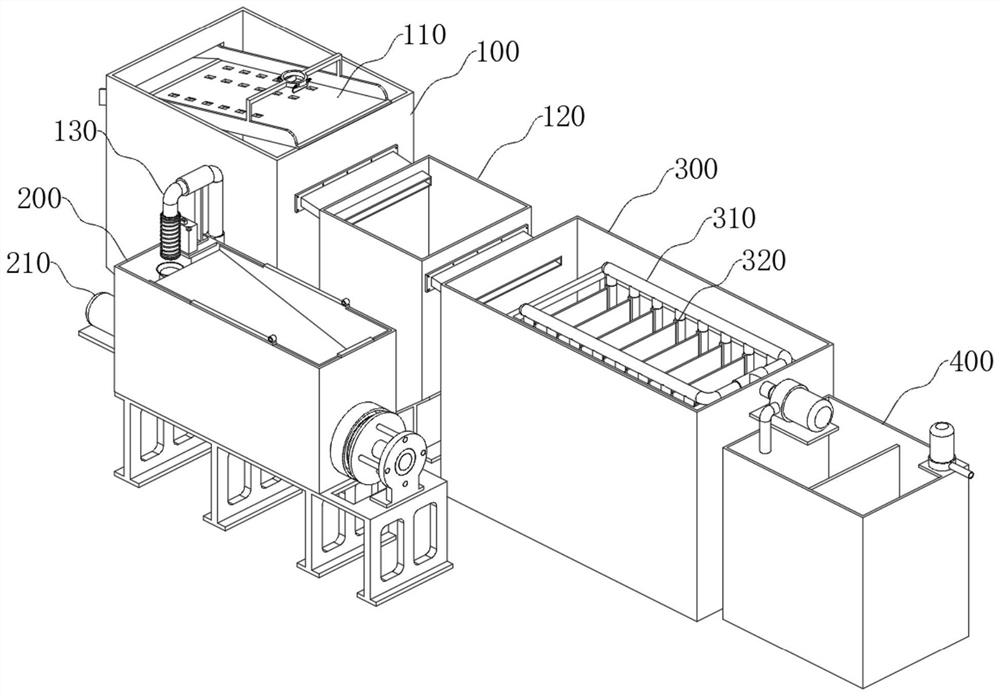

A sewage treatment and waste recycling technology, applied in the field of water pollution treatment, can solve the problems of inability to realize waste reuse and low waste utilization rate, and achieve the effect of ingenious structure, automatic structure and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The invention provides a process for recycling waste in sewage treatment, comprising the following steps:

[0069] 1. Waste and wastewater separation stage:

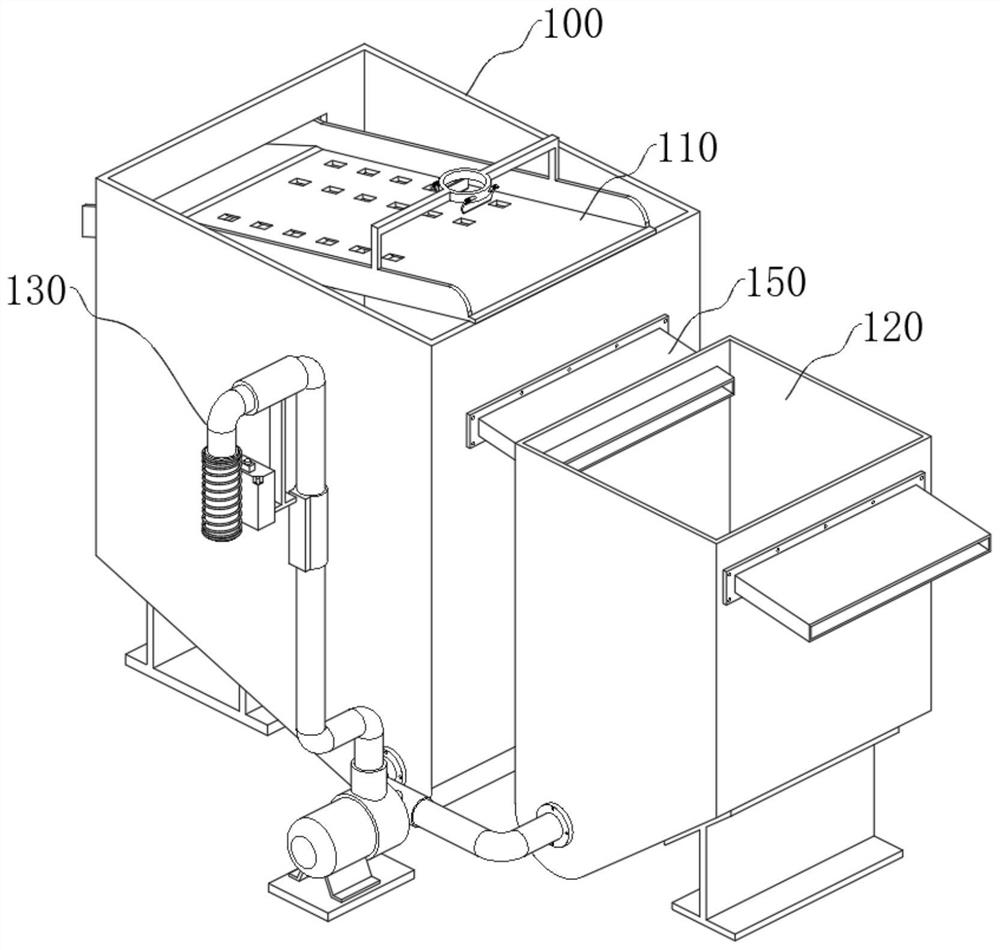

[0070] S1. First put the waste and wastewater delivery pipe into the pipe sleeve 113 and be clamped by a pair of clamping plates 114, then start the water pump at the other end of the delivery pipe to suck the waste and wastewater mixture out of the delivery pipe and fall into the screening on the screen plate 110 at the top of the pool 100;

[0071] S2. Then the mixed liquid of waste and wastewater flows along the top surface of the screening plate 110, the waste water falls into the screening tank 100 from the seepage hole 111 and precipitates, and the waste slides to the outside of the screening tank 100 and falls to be collected;

[0072] Wherein the sedimentation water in the screening tank 100 accumulates and rises and overflows into the sedimentation tank 120 for secondary sedimentation;

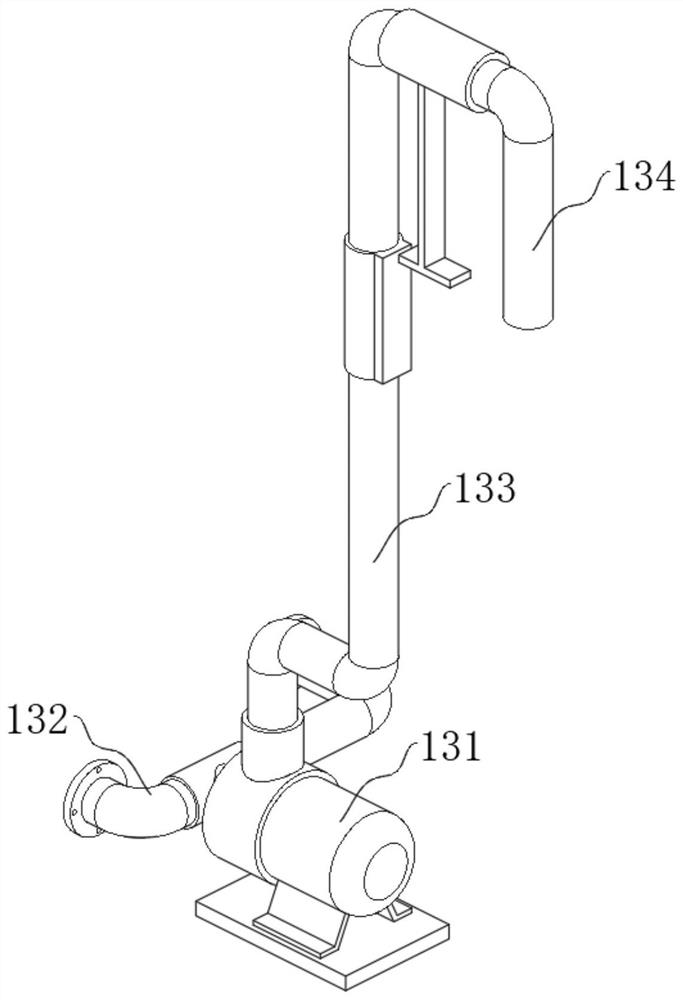

[0073] 2. Mud t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com