Electroplating wastewater treatment tank

A technology for electroplating wastewater and treatment tank, which is applied in the fields of metallurgical wastewater treatment, water/sewage treatment, flotation water/sewage treatment, etc. Clean up troubles and other problems to achieve the effect of high cost performance, saving manpower and material resources, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

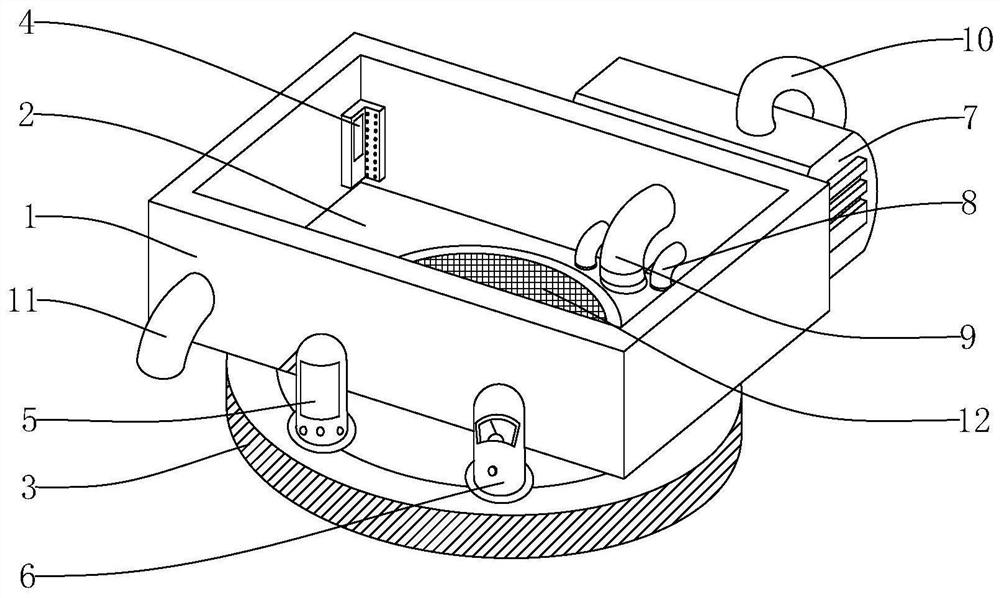

[0032] As a specific embodiment of the present invention, the air flotation machine 3 is vertically installed directly below the water storage tank 2, and there is a circular partition 12 between the air flotation machine 3 and the water storage tank 2;

[0033] Because the air flotation machine 3 is vertically installed directly below the reservoir 2, the air bubbles produced by the air flotation machine 3 can directly reach the reservoir 2, and there is a circular layer between the air flotation machine 3 and the reservoir 2. Partition net 12, has avoided impurity and can not damage air flotation machine 3.

[0034] As a specific embodiment of the present invention, the conversion machine 7 is installed horizontally at the rear end of the enclosure wall 1, and the drain port 8 and the water inlet 9 are fixed inside the conversion machine 7 and fixed to the reservoir 2 through the enclosure wall 1. surface;

[0035] Since the conversion machine 7 is horizontally installed at...

Embodiment approach

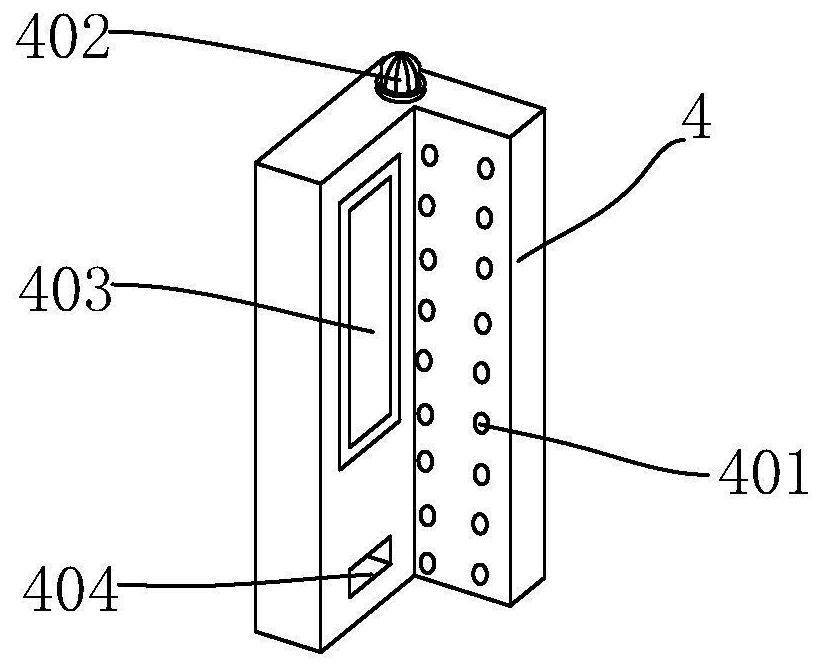

[0036] As a specific embodiment of the present invention, a total of 18 detection holes 401 are arranged on the right surface of the detector 4, and these detection holes 401 are vertically and equidistantly arranged;

[0037] Since a total of 18 detection holes 401 are arranged on the right surface of the detector 4, when the water overflows the detector 4, a plurality of detection holes 401 can quickly start detection and provide feedback, and these detection holes 401 are vertically equidistantly arranged, The detector 4 can detect the pollution of different water levels.

[0038] As a specific embodiment of the present invention, the warning light 402 is semicircular, and the warning light 402 is installed vertically on the upper end of the detector 4;

[0039] Because the warning light 402 is semicircular, it is easier for workers to observe the alarm, and the warning light 402 is vertically installed on the upper end of the detector 4, so that the workers can be notified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com