Dual anti-seepage and anti-corrosion structure of wastewater lifting device

A dual, waste water technology, applied in lamination devices, anti-corrosion coatings, solid waste management, etc., can solve the problems of poor anti-seepage and anti-corrosion durability, high cost, poor anti-seepage effect, etc., to increase compatibility and reactivity, Good integrity, quicker drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation process of the high-strength glass fiber comprises:

[0042] A, prepare the first component glass paste and the second component glass paste respectively;

[0043] The first component glass paste includes the following raw materials in parts by weight: 55-57 parts of quartz stone, 10-17 parts of pyrophyllite, 12-25 parts of limestone, 5-8 parts of MgO, 15-20 parts of soda ash, tallow amine polyoxyethylene 1-3 parts of ether hydrochloride, 40-60 parts of ethanol, 25-40 parts of deionized water; the second component glass slurry includes the following raw materials in parts by weight: 55-57 parts of quartz stone, 10-17 parts of pyrophyllite 12-25 parts of limestone, 5-8 parts of MgO, 15-20 parts of soda ash, 0.5-1.5 parts of 2-ethylhexyl sodium phosphate diester, 0.5-1.5 parts of binder, 40-60 parts of ethanol, 25-40 parts of ionized water. The binder is composed of glycidyl ester, sodium lignosulfonate and isocyanate in a mass ratio of 0.8-1.2:1:1-1.5; ...

Embodiment 1

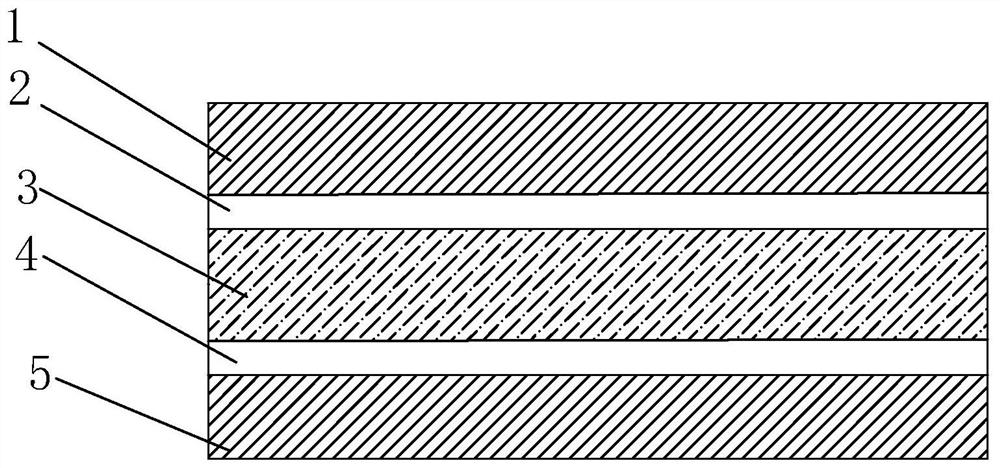

[0049] A double anti-seepage and anti-corrosion structure of a wastewater lifting device, comprising an inner high-strength glass fiber layer 1, a first middle layer 2, an inner structural layer 3, a second middle layer 4, and an outer high-strength glass fiber layer 5 arranged in sequence.

[0050] The double anti-seepage and anti-corrosion structure of the wastewater lifting device includes the following preparation steps:

[0051] 1) Inner structural layer: use concrete to prepare the inner structural layer according to the shape of the device as the base structure, and cure at room temperature for 25 hours;

[0052] 2) Middle layer: Coat resin mastic on the basis of the inner structural layer, finish and smooth, and cure at room temperature for 23 hours;

[0053] 3) High-strength glass fiber layer: first coat rubber on the surface of the above-mentioned first intermediate layer and second intermediate layer, then spread the high-strength glass fiber layer, then coat the ru...

Embodiment 2

[0062] A double anti-seepage and anti-corrosion structure of a wastewater lifting device, comprising an inner high-strength glass fiber layer 1, a first middle layer 2, an inner structural layer 3, a second middle layer 4, and an outer high-strength glass fiber layer 5 arranged in sequence.

[0063] The double anti-seepage and anti-corrosion structure of the wastewater lifting device includes the following preparation steps:

[0064] 1) Inner structural layer: use concrete to prepare the inner structural layer according to the shape of the device as the base structure, and cure at room temperature for 24 hours;

[0065] 2) Middle layer: Coat resin mastic material on the basis of the inner structural layer, finish and smooth, and cure at room temperature for 22 hours;

[0066] 3) High-strength glass fiber layer: first coat rubber on the surface of the above-mentioned first intermediate layer and second intermediate layer, then spread the high-strength glass fiber layer, then co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com