Puncture-resistant high-wear-resistant woven curtain and preparation method thereof

A technology with high wear resistance and puncture resistance, applied in the field of curtains, can solve the problems of heavy weight, thick thickness, lack of flexibility and comfort, etc., and achieve the effect of good restoration of original shape, strong puncture resistance and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

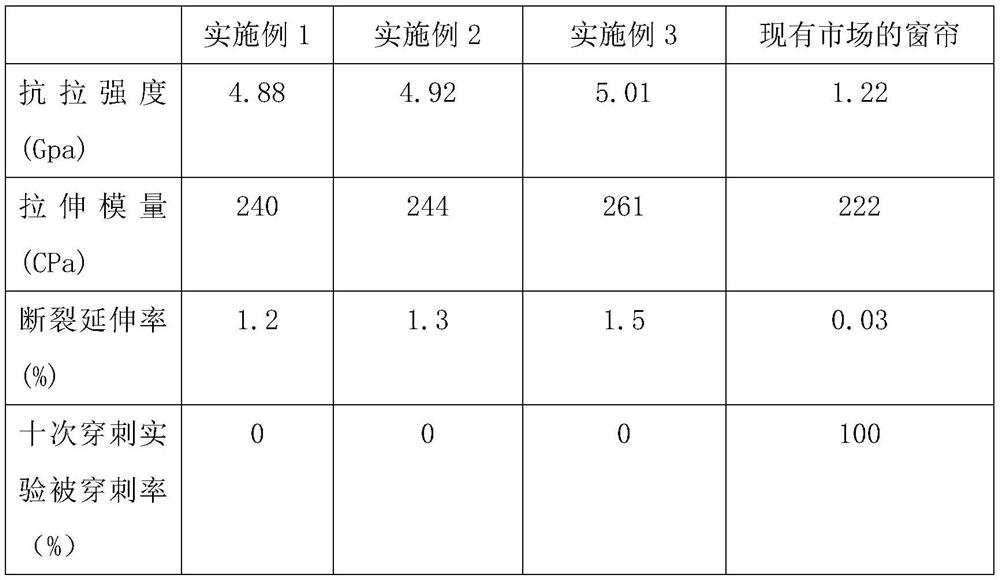

Examples

Embodiment 1

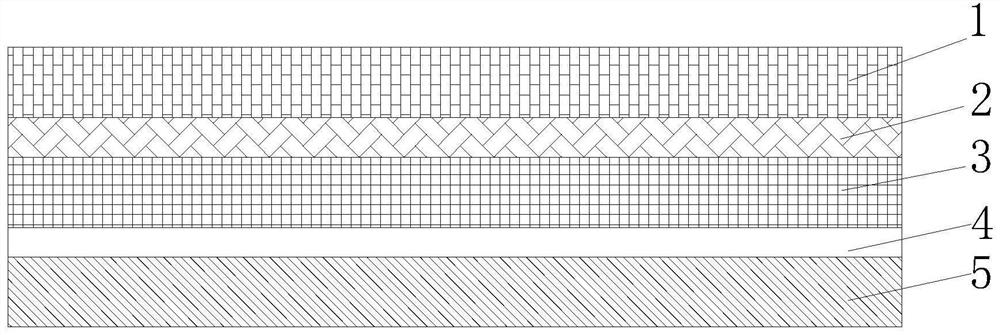

[0041] S1. Preparation of the outer sheath 1: Opening, mixing and carding the highly wear-resistant TPU sheath-core monofilament yarn in sequence, adding ultra-high-strength polyethylene fibers in the TPU sheath-core monofilament yarn, and then Laying and pre-needling treatment, thermal bonding and reinforcement processing at 180°C, the hot pressing speed is 0.5m / min;

[0042] S2. Preparation of the puncture-resistant layer 3: firstly, the polyester fiber and the PBO fiber are sequentially opened, mixed, carded, and woven into threads, and are woven and connected into a puncture-resistant woven fabric through the "joint bonding method";

[0043] S3, the preparation of the connecting layer 2 thread: the stainless steel spun yarn is spun by spinning technology, and the stainless steel spun yarn is coated with aluminum foil to make a stainless steel twisted yarn;

[0044] S4. Preparation of polyurethane adhesive: Utilize the following weight-to-component ratio: 100 parts of toluene...

Embodiment 2

[0048] S1. Preparation of the outer sheath 1: Opening, mixing and carding the highly wear-resistant TPU sheath-core monofilament yarn in sequence, adding ultra-high-strength polyethylene fibers in the TPU sheath-core monofilament yarn, and then Laying and pre-needling treatment, thermal bonding and reinforcement processing at 180°C, the hot pressing speed is 0.5m / min;

[0049] S2. Preparation of the puncture-resistant layer 3: firstly, the polyester fiber and the PBO fiber are sequentially opened, mixed, carded, and woven into threads, and are woven and connected into a puncture-resistant woven fabric through the "joint bonding method";

[0050] S3, the preparation of the connecting layer 2 thread: the stainless steel spun yarn is spun by spinning technology, and the stainless steel spun yarn is coated with aluminum foil to make a stainless steel twisted yarn;

[0051] S4. Preparation of polyurethane adhesive: Utilize the following weight-to-component ratio: 100 parts of tolue...

Embodiment 3

[0055] S1. Preparation of the outer sheath 1: Opening, mixing and carding the highly wear-resistant TPU sheath-core monofilament yarn in sequence, adding ultra-high-strength polyethylene fibers in the TPU sheath-core monofilament yarn, and then Laying and pre-needling treatment, thermal bonding and reinforcement processing at 170°C, the hot pressing speed is 0.5m / min;

[0056] S2. Preparation of the puncture-resistant layer 3: firstly, the polyester fiber and the PBO fiber are sequentially opened, mixed, carded, and woven into threads, and are woven and connected into a puncture-resistant woven fabric through the "joint bonding method";

[0057] S3, the preparation of the connecting layer 2 thread: the stainless steel spun yarn is spun by spinning technology, and the stainless steel spun yarn is coated with aluminum foil to make a stainless steel twisted yarn;

[0058] S4. Preparation of polyurethane adhesive: Utilize the following weight-to-component ratio: 100 parts of tolue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com