Production process of antibacterial regenerated polyester staple fibers

A technology of recycled polyester and production process, which is applied in fiber processing, filament forming processing, filament/thread forming, etc., can solve the problems of weak strength performance, limited market promotion, and difficulty in meeting the raw material strength from renewable resources, and achieves strength improvement. , Guarantee the efficiency, the effect of inhibiting the production of white powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

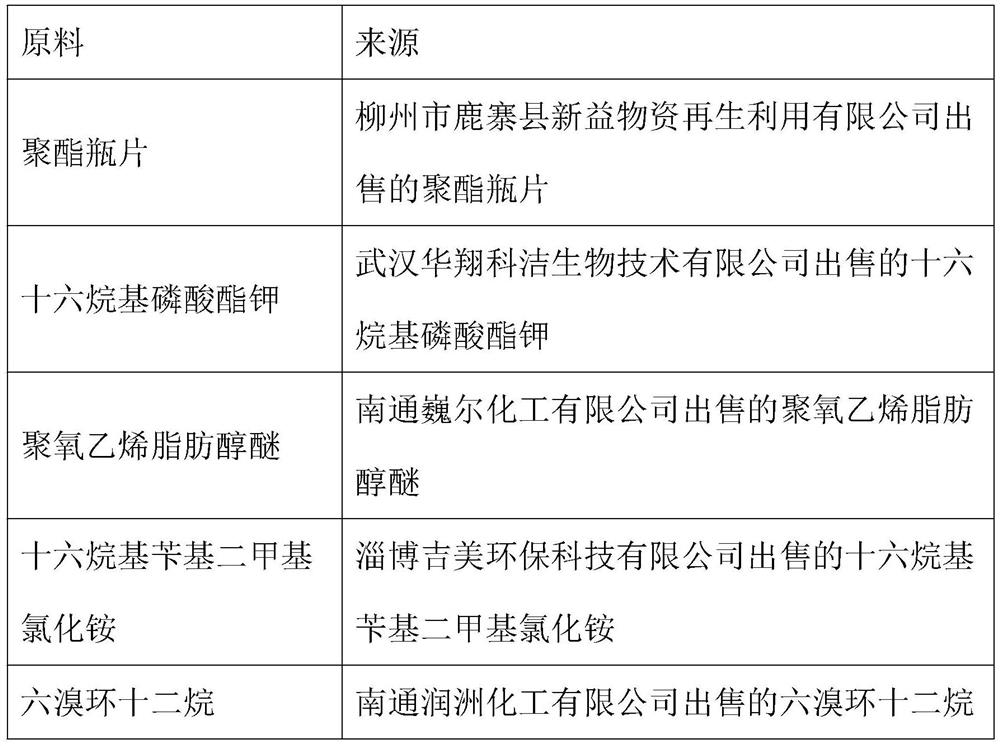

[0055] Embodiment 1-3: This embodiment discloses an oil agent, which specifically includes the following components:

[0056] Polyoxyethylene fatty alcohol ether, potassium cetyl phosphate, cetyl benzyl dimethyl ammonium chloride, water.

[0057] In embodiment 1-3, the input amount (unit Kg) of each component sees table 2 for details

[0058] Table 2

[0059]

[0060] The preparation method of the oil agent is as follows: add polyoxyethylene fatty alcohol ether, potassium cetyl phosphate, and cetyl benzyl dimethyl ammonium chloride into a stirring tank equipped with water, stir while adding, and Under the condition of power of 900W and transmission frequency of 25kHz, the water bath ultrasonically oscillates for 2h.

Embodiment 4-6

[0061] Embodiment 4-6: This embodiment discloses a kind of oil agent, also adds following component:

[0062] Hexabromocyclododecane.

[0063] In embodiment 4-6, the input amount (unit Kg) of each component sees table 3 for details

[0064] table 3

[0065]

[0066] Add hexabromocyclododecane, polyoxyethylene fatty alcohol ether, potassium cetyl phosphate, and cetyl benzyl dimethyl ammonium chloride into a stirring tank filled with water.

Embodiment 7-9

[0067] Embodiment 7-9: This embodiment discloses a kind of oil preparation, also adds following component:

[0068] Hexabromocyclododecane, tricresyl phosphate.

[0069] In embodiment 7-9, the input amount (unit Kg) of each component sees table 4 for details

[0070] Table 4

[0071]

[0072]

[0073] Add hexabromocyclododecane, tricresyl phosphate, polyoxyethylene fatty alcohol ether, potassium cetyl phosphate, and cetyl benzyl dimethyl ammonium chloride into a stirring tank filled with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com