Anti-pulverization production technology of synthetic slag lotion

A production process and technology of slag lotion, which is applied in the anti-powdering production process field of synthetic slag lotion, can solve problems such as the reduction of effective components of CaO, the loss of active components of products, and the impact on desulfurization effect of products, so as to achieve less residual material and avoid Sphere volume expansion phenomenon, the effect of improving the operating environment of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

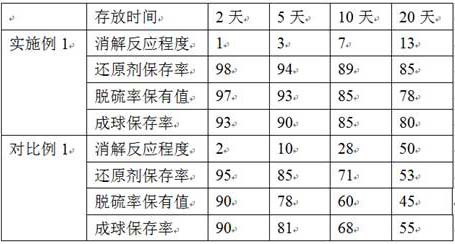

Embodiment 1

[0047] Taking the synthetic slag washing material of a steel factory in Handan as an example, the chemical composition of the synthetic slag washing agent is calculated in parts by weight: 20-50 parts of activated lime, 20-40 parts of high-alumina bauxite clinker, 10-30 parts Part of AD powder, 5~15 parts of fluorite; Among them, the content of CaO in activated lime is ≥85%, the particle size is 0~3mm≥80%; the particle size of high alumina clinker is 0~3mm≥80%; CaF in stone 2 The content is ≥65%, and the particle size is 0~3mm≥80%.

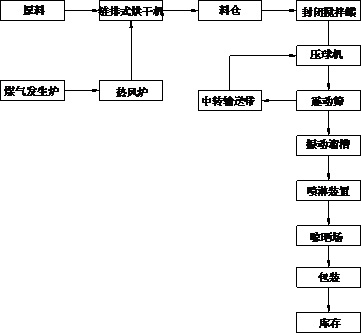

[0048] refer to figure 1 , a kind of anti-powdering production process of synthetic slag lotion, comprises the following steps successively:

[0049] A. Raw material preparation: According to the granularity requirements of the raw materials in the product formula, sieve the activated lime, high alumina bauxite clinker and fluorite to the corresponding particle size, measure and screen the components of each raw material to ensure the CaO conten...

Embodiment 2

[0061] In the anti-powdering production process of the synthetic slag lotion described in this embodiment, the chemical composition of the synthetic slag lotion is the same as in Example 1, except that:

[0062] B. Drying: During the drying process, according to the original moisture content of each raw material, the feeding speed of the chain row dryer is controlled at 3 m / min, and the induced air temperature is controlled at 150°C, so that the moisture in each raw material after drying Mass percentage content <0.2%;

[0063] D. Stirring: According to the proportion of the above raw materials, according to the production tonnage of 1 ton each time, the computer batching system calculates the quality of each raw material, automatically controls the feeding and transports it to the closed mixing tank; each production is required Quality error <±5kg; according to product quality requirements, control the stirring time at 15 minutes;

[0064] F. Ball briquetting: When the materi...

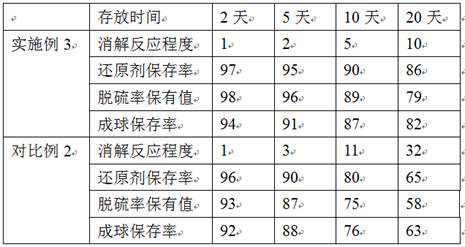

Embodiment 3

[0086] Taking the composite slag washing material of a steel factory in Tangshan as an example, the chemical composition of the synthetic slag washing agent is calculated in parts by weight: 30-60 parts of sintering and refining slag, 10-20 parts of silicon-calcium alloy waste slag, 10-30 parts bauxite, 5~15 parts of industrial soda; the particle size of the above materials is 0~3mm≥90%; among them, the content of CaO in the premelted refining slag is ≥45%, Al 2 o 3 The content of [Ca] in silicon-calcium alloy waste residue is ≥ 38%, the content of [Si] is ≥ 20%, and the content of [Si] in bauxite is ≥ 20%. 2 o 3 content ≥ 65%.

[0087] refer to figure 1 , the anti-powdering production process of a synthetic slag lotion in this embodiment, the basic steps are the same as in Example 1, the difference is:

[0088] B. Drying: During the drying process, according to the original moisture content of each raw material, the feeding speed of the chain row dryer is controlled at 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com