Synthesis method of diglyceride

A synthesis method, the technology of diglyceride, which is applied in the field of synthesis of diglyceride, can solve the problems of reduced purity of diglyceride, excessive hydrolysis of diglyceride, narrow controllable range, etc., and achieves the convenience of industrial production and low production cost , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The inventors of the present invention discovered for the first time that, unlike conventional lipases, these two lipases (especially MAS1-H108A) have a greater tendency to hydrolyze triglycerides than diglycerides. Based on this discovery, the inventors of the present invention combined their own long-term experience and a large amount of scientific research to explore, and finally obtained a method for synthesizing diglyceride of the present invention, including the following steps:

[0039] (1) mixing grease, lipase and a solvent to carry out a hydrolysis reaction to obtain a hydrolyzate;

[0040] (2) Under the action of diglyceride lipase, the hydrolyzate obtained in step (1) is subjected to an esterification reaction with glycerin;

[0041] The lipase in step (1) is lipase MAS1 or MAS1-H108A.

[0042] The lipase MAS1 of the present invention is a wild type, derived from the actinomycete Streptomycetes sp. StrainW007, and the lipase MAS1-H108A is a mutant of the w...

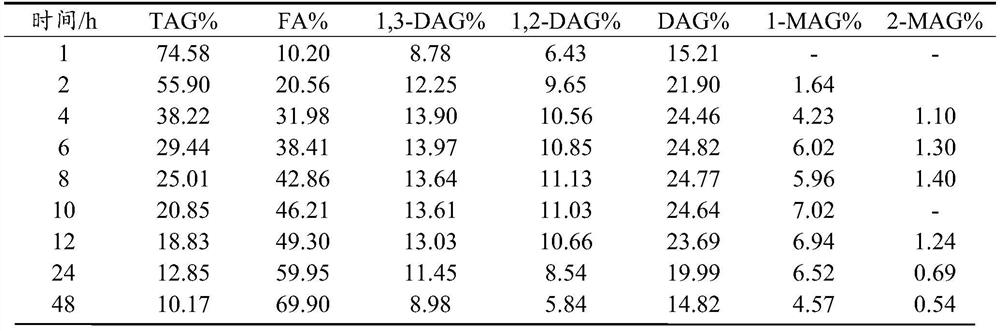

Embodiment 1

[0065] (1) Hydrolysis: Add soybean oil and a phosphate buffer solution with a pH of 7.5 in a stoppered Erlenmeyer flask, the mass ratio of which is 1:0.5, and place it on a constant temperature magnetic stirrer with a rotation speed of 500rpm to preheat at 40°C for 10min. Add 500U / g of triglyceride lipase Lipase MAS1-H108A (based on the total mass of oil) after the end of the heat, take a sample for detection at 8 hours, let stand for stratification, get the oil phase as the hydrolyzate and reclaim the water phase, the gained oil phase does not need Separation of fatty acids and glycerides. The fatty acid content in the obtained hydrolyzate is 60.2%, the diglyceride content is 20.5%, and the triglyceride content is 12.3%.

[0066] (2) Esterification: put the hydrolyzate and glycerin in a mass ratio (1:1), put them into a stoppered Erlenmeyer flask, and place them on a constant temperature magnetic stirrer with a rotation speed of 500rpm to preheat at 40°C for 10min, and then a...

Embodiment 2

[0068] (1) Hydrolysis: Add soybean oil and a phosphate buffer solution with a pH of 7.5 in a stoppered Erlenmeyer flask, the mass ratio of which is 1:0.5, and place it on a constant temperature magnetic stirrer with a rotation speed of 500rpm to preheat at 40°C for 10min. Add 500U / g of triglyceride lipase Lipase MAS1-H108A (based on the total mass of the oil) after the heat is over, take a sample for 12h for detection, let stand and separate, take the oil phase as the hydrolyzate and recover the water phase, and the obtained oil phase does not need to be separated fatty acids and glycerides. The fatty acid content in the obtained hydrolyzate is 70.1%, the diglyceride content is 15.6%, and the triglyceride content is 10.5%.

[0069] (2) Esterification: put the hydrolyzate and glycerin in a mass ratio (1:1), put them into a stoppered Erlenmeyer flask, and place them on a constant temperature magnetic stirrer with a rotation speed of 500rpm to preheat at 40°C for 10min, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com