Bulk polymer and preparation method and application thereof

A polymer, comb polymer technology, applied in the polymer field, can solve the problems of high viscosity, high cost, difficult mass and heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

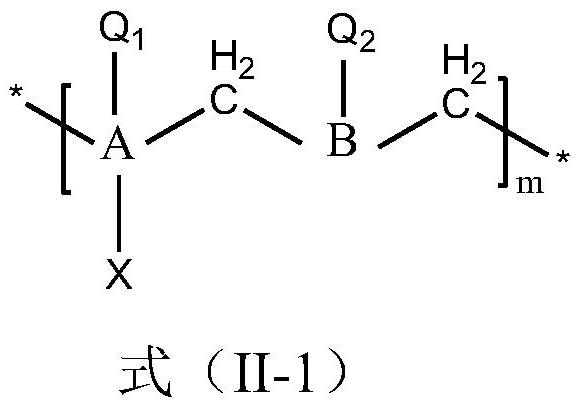

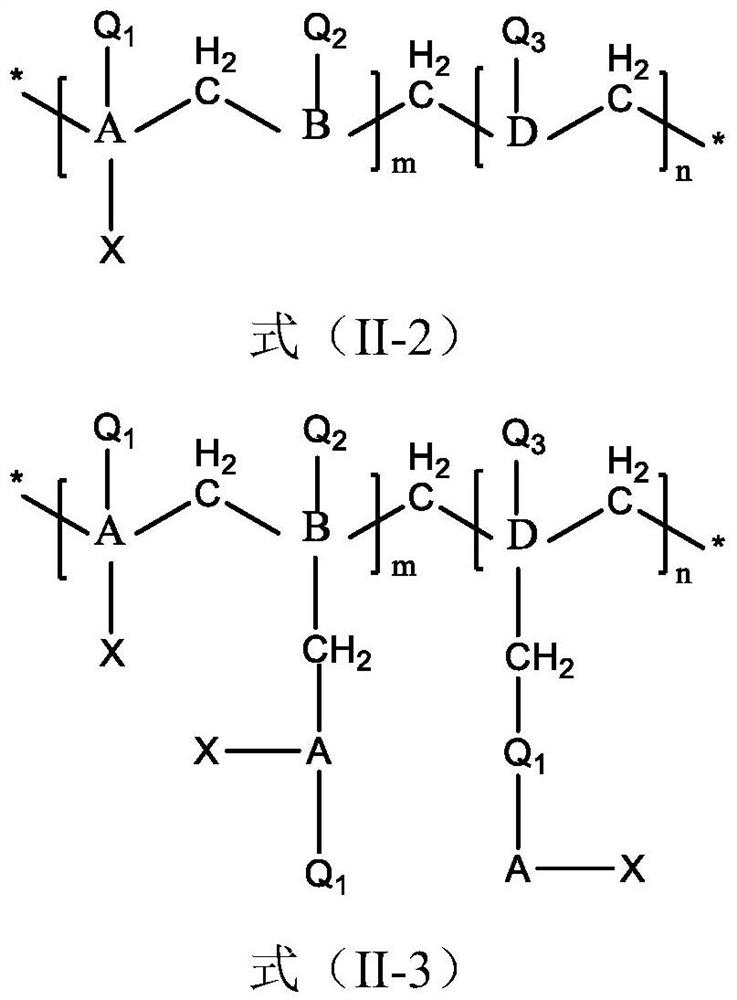

Method used

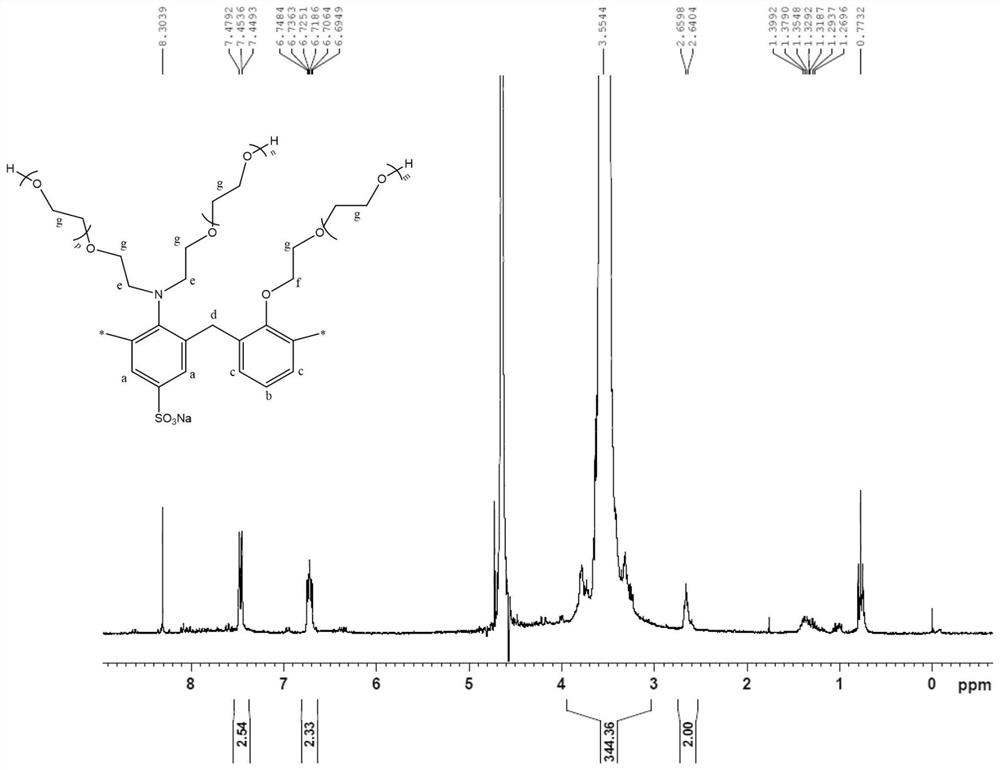

Image

Examples

Embodiment 1

[0091] Preparation of step 1-initiator (sulfamic acid acetal water-soluble resin):

[0092] In this example, p-aminobenzenesulfonic acid with an initial mass fraction of 10-40% and 2-25% phenol are used to prepare an aqueous solution with a mass content of 25-50% by adding water, heated to 50-100°C, and adding sulfuric acid to adjust the pH of the system In the range of 3<pH<5, formaldehyde solution with a mass fraction of 8-45% is slowly added dropwise to the system for polycondensation reaction, and the dropping time is controlled within 1-3 hours. After the dropwise addition is completed, add sodium hydroxide to the system, adjust the pH value of the system to 8-9, continue to maintain the temperature at 50-100°C, and add urea aqueous solution with a mass fraction of 1-5% to the system for alkaline condensation. Condensation time 2 ~ 7h. After the alkaline condensation is completed, add sodium hydroxide to the system to adjust the pH value to 10-12, and control the tempera...

Embodiment 2

[0104] Step 1—Preparation of initiator (sulfamic acid acetal water-soluble resin): the initiator prepared in Example 1 was used.

[0105] Step 2 - Purification and alkoxylation of starter

[0106] Purify and separate the starter obtained in step 1, and keep the weight average molecular weight: 1000-2000g / mol, 2000-3000g / mol, 3000-5000g / mol, 5000-7000g / mol.

[0107] Weigh the initiators in different molecular weight ranges, add potassium hydroxide whose mass fraction is 0.01% to 0.3% of the initiator mass, dehydrate and dry, control the moisture content of the initiators to be less than 500ppm, and remove impurities, purify and separate the initiators The initiator and the solvent dimethyl sulfoxide are put into the alkoxylation reaction kettle according to the mass ratio of 90:10. After nitrogen replacement and deoxygenation, the solution is heated to 120-170°C, and then ethylene oxide is passed through Addition reaction is carried out according to the molar ratio of starter:...

Embodiment 3

[0113] Step 1—Preparation of initiator (sulfamic acid acetal water-soluble resin): the initiator prepared in Example 1 was used.

[0114] Step 2 - Purification and alkoxylation of starter

[0115] Purify and separate the starter obtained in step 1, and keep the weight average molecular weight: 1000-2000g / mol, 2000-3000g / mol, 3000-5000g / mol, 5000-7000g / mol.

[0116] Weigh the initiators in different molecular weight ranges, add potassium hydroxide whose mass fraction is 0.01% to 0.3% of the initiator mass, dehydrate and dry, control the moisture content of the initiators to be less than 500ppm, and remove impurities, purify and separate the initiators The initiator and the solvent dimethyl sulfoxide are put into the alkoxylation reaction kettle according to the mass ratio of 90:10. After nitrogen replacement and deoxygenation, the solution is heated to 120-170°C, and then ethylene oxide is passed through Addition reaction is carried out according to the molar ratio of starter:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com