Preparation method, application and use method of capsaicin molecularly imprinted magnetic beads

A technology of molecular imprinting and capsaicin, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of poor selectivity and low extraction efficiency of capsaicin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

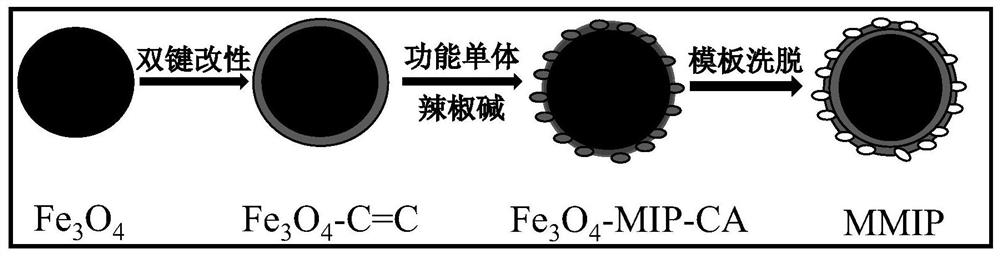

[0027] 1. Double bond modification:

[0028] Add 0.1g of ferric oxide and 2mL of NH to 100mL of absolute ethanol solution 3 ·H 2 O and 1mL of γ-methacryloxypropyltrimethoxysilane (MPS), after ultrasonic mixing, heated to reflux for 5h, after the reaction was complete, washed with ethanol, set to 50mL.

[0029] 2. Molecular imprinting polymerization of capsaicin:

[0030] Add 50mL of double-bond-modified ferric oxide, 50mL of ethanol, 0.05g of dihydrocapsaicin, 90mL of toluene, and 50μL of methacrylic acid (MAA) into a three-necked flask, oscillate ultrasonically for 15min, and keep away from light for 12h to form a template-monomer Prepolymer, then add 1.2mL cross-linking agent ethylene glycol dimethacrylate (EGDMA) and 0.2g initiator 2,2 azobisisobutyronitrile (AIBN) successively, and ultrasonically vibrate for 15min at room temperature. Mechanically stir the reaction in a water bath at 65°C for 10 hours. After cooling, remove unreacted functional monomers and template mol...

Embodiment 2

[0039] 1. Double bond modification:

[0040] Add 0.1g of ferric oxide and 2mL of NH to 100mL of absolute ethanol solution 3 ·H 2 O and 1mL oleic acid, after ultrasonic mixing, heated to reflux for 5h, after the reaction was complete, washed with ethanol until no free oleic acid, toluene to 50mL.

[0041] 2. Molecular imprinting polymerization of capsaicin:

[0042] Add 50mL of double-bond modified ferric oxide, 0.1g of natural capsaicin, 90mL of toluene, and 200μL of methacrylic acid (MAA) into the three-necked flask, oscillate ultrasonically for 15min, and keep away from light for 12h to form a template-monomer prepolymer. Then add 1.2mL of cross-linking agent ethylene glycol dimethacrylate (EGDMA) and 0.2g of initiator 2,2-azobisisobutyronitrile (AIBN) successively, ultrasonically shake for 15min at room temperature, and place in a water bath at 65°C Mechanically stirred and reacted for 12 hours, and after cooling, unreacted functional monomers and template molecules were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com