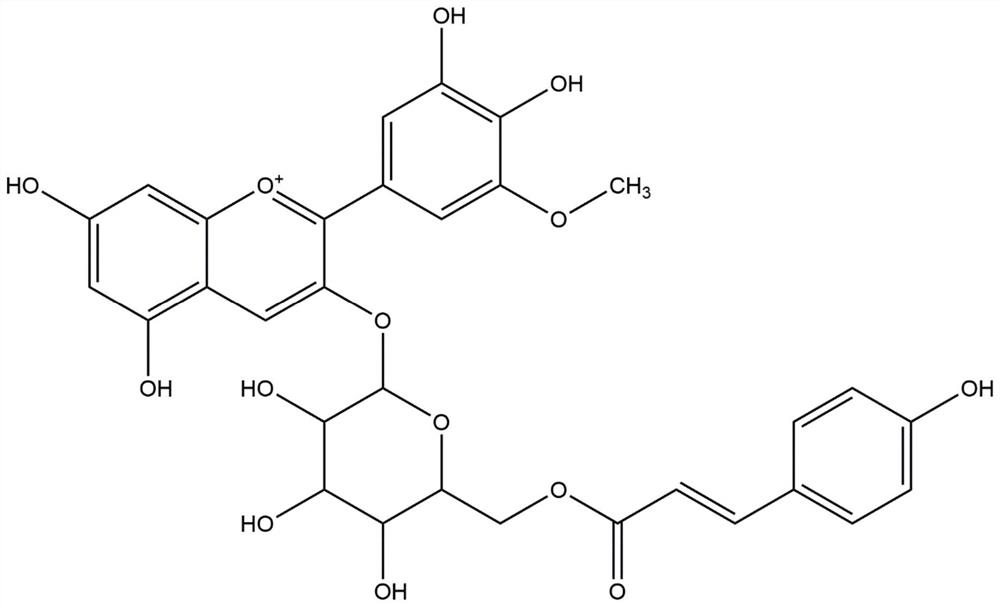

Method for separating and preparing petunidin-3-O-(6-O-p-coumaroyl) glucoside

A technology for petunienin and glucoside, which is applied in the field of separation and preparation of petunienin-3-O-glucoside, which can solve the problem of no acylated anthocyanin, difficulty in separation and purification of acylated anthocyanin, and difficulty in obtaining target anthocyanin and other problems, to achieve the effect of large processing volume and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

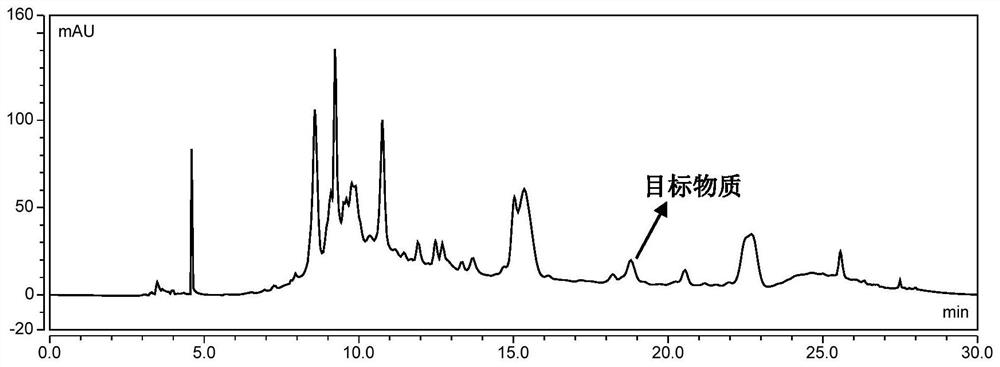

[0048] Wash and peel the grapes to obtain 1 kg of grape skins, add 70% ethanol solution containing 0.5% (v / v) hydrochloric acid according to the ratio of solid to liquid 1g: 6mL, mix well, and extract by ultrasonic for 60min, (control the temperature below 50°C , protected from light), filtered through gauze, the filtrate was centrifuged at 4000rpm for 10min, and the supernatant was taken. The filter residue was extracted once more in the same way. The filtrates were combined and filtered one more time using a Buchner funnel. The filtrate was evaporated under reduced pressure at 45°C to remove ethanol and concentrated to obtain a crude grape skin anthocyanin extract. The high performance liquid chromatogram of grape skin anthocyanin crude extract is as follows figure 2 shown.

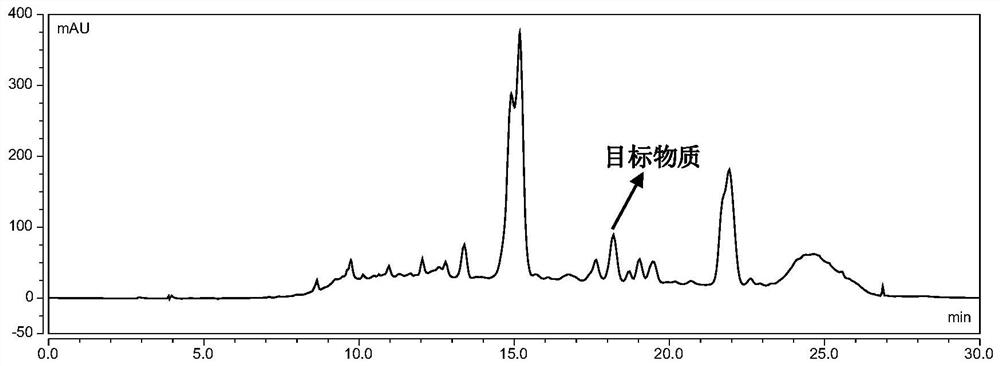

[0049] Put the AB-8 macroporous resin into the chromatographic column, and use ethanol, 0.5mol / L hydrochloric acid solution, 0.5mol / L sodium hydroxide solution, and water to wash in sequence, and th...

Embodiment 2

[0054] Wash and peel the grapes to obtain 4kg of grape skins, add 70% ethanol solution containing 0.5% (v / v) hydrochloric acid according to the ratio of solid to liquid 1g: 6mL, mix well, and ultrasonically extract for 90min, (control the temperature below 50°C , protected from light), filtered through gauze, the filtrate was centrifuged at 4000rpm for 10min, and the supernatant was taken. The filter residue was extracted once more in the same way. The filtrates were combined and filtered one more time using a Buchner funnel. The filtrate was evaporated under reduced pressure at 45°C to remove ethanol and concentrated to obtain a crude grape skin anthocyanin extract.

[0055] Put the AB-8 macroporous resin into the chromatographic column, and use ethanol, 0.5mol / L hydrochloric acid solution, 0.5mol / L sodium hydroxide solution, and water to wash in sequence, and then wash the crude anthocyanin extract at 0.2BV / The flow rate of h is injected into the chromatography column. A...

Embodiment 3

[0059] Wash and peel the grapes to obtain 10kg of grape skins, add 70% ethanol solution containing 0.5% (v / v) hydrochloric acid according to the ratio of solid to liquid 1g: 6mL, fully mix, ultrasonically extract for 60min, (control the temperature below 50°C , protected from light), filtered through gauze, the filtrate was centrifuged at 4000rpm for 10min, and the supernatant was taken. The filter residue was extracted once more in the same way. The filtrates were combined and filtered one more time using a Buchner funnel. The filtrate was evaporated under reduced pressure at 45°C to remove ethanol and concentrated to obtain a crude grape skin anthocyanin extract.

[0060] Put the AB-8 macroporous resin into the chromatographic column, and use ethanol, 0.5mol / L hydrochloric acid solution, 0.5mol / L sodium hydroxide solution, and water to wash in sequence, and then wash the crude anthocyanin extract at 0.2BV / The flow rate of h is injected into the chromatography column. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com