Cigarette case production system and process with efficient printing performance

A production system and cigarette case technology, applied in the field of cigarette case production system and its process, can solve the problems of waste of resources, influence of spraying effect, time-consuming and laborious internal precision components, etc., and achieve the effect of facilitating cutting and collection and reducing resource consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

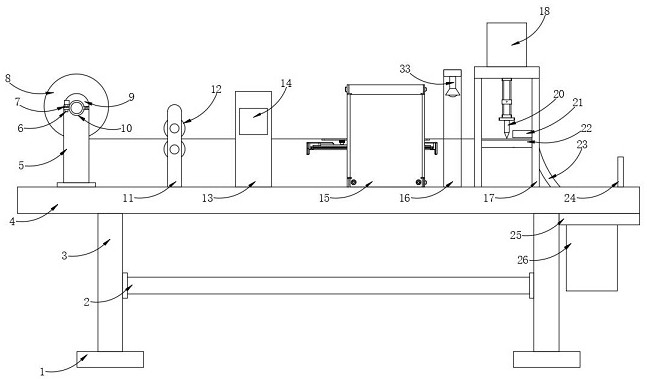

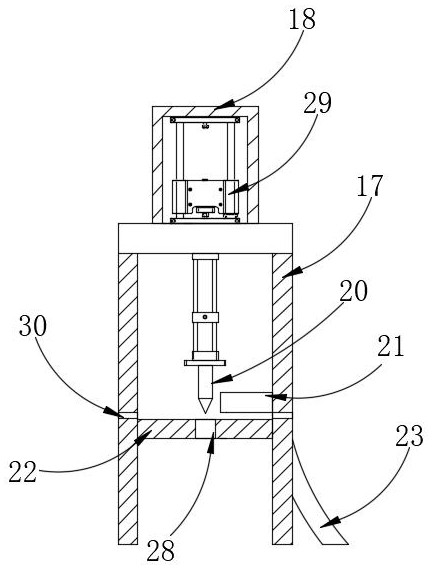

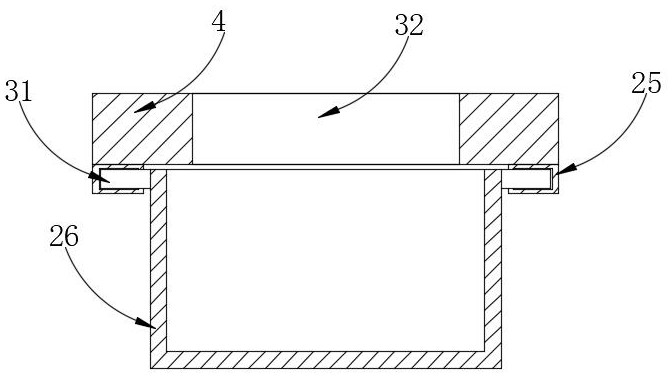

[0041] see Figure 1~4, a cigarette box production system with high-efficiency printing performance and its technology related to the present invention, comprising a plate body a-4, two shells a-5 are symmetrically welded on the upper surface of the plate body a-4, and the two shells The upper surfaces of a-5 are hinged with housing b-9 through pin shafts, and the repelling sides of the two housings a-5 and the repelling sides of the two housings b-9 are welded with fixed blocks 7, four The inner sidewalls of the fixed block 7 are all threaded with bolts 6, and the tops of the two housings a-5 and the bottoms of the two housings b-9 are provided with grooves 10, and the inner sidewalls of the grooves 10 are connected by rotating shafts. Paper roll 8, plate c-13 is symmetrically welded on the upper surface of plate body a-4, and the adjacent sides of two plate bodies c-13 are symmetrically connected with two rotating rollers b-27 through bearing rotation, one plate body One si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com