Side spiral electromagnetic stirring device

A technology of helical electromagnetic stirring and power supply device is applied in the field of continuous casting technology and semi-continuous casting. Small footprint, low cost, and improved solidification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

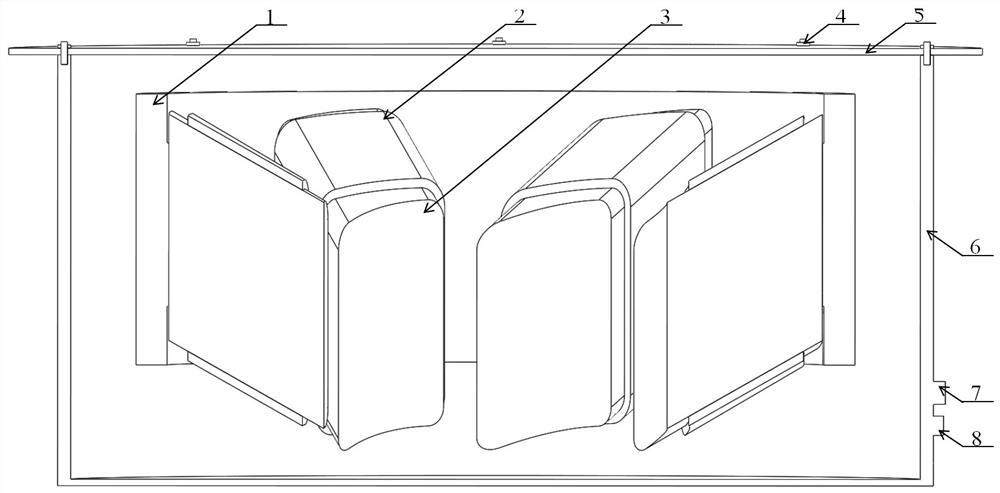

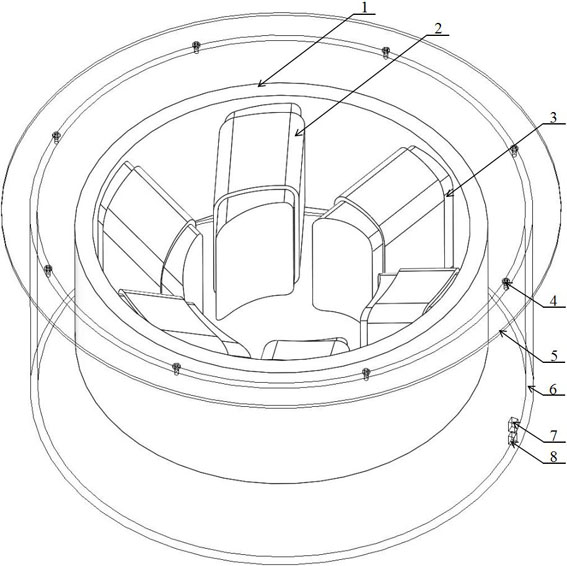

[0023] In this embodiment, the side screw electromagnetic stirring device is produced according to the following steps:

[0024] A. Production of P91 steel grade, round billet with a section diameter of 800mm, casting speed of the continuous casting machine is 0.23m / min, molten steel is injected into the water-cooled crystallizer through the submerged nozzle; at the beginning of continuous casting, the secondary cooling system, side spiral electromagnetic stirring The device and the nip roller device start automatically and synchronously.

[0025] B. The average specific water volume of the secondary cooling system is 0.19L / kg. The yoke 3 of the side spiral electromagnetic stirring device selects a longitudinal inclination angle of 30°, a lateral inclination angle of 10°, and the horizontal width of the yoke 3 is 300mm; the current of the coil 2 is 850A, the frequency is 6Hz; the height of the yoke fixing plate 1 is 600mm; the side spiral electromagnetic stirring device is ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com