Thermoelectric power generation module for fluid waste heat recovery, and structure optimization method thereof

A thermoelectric power generation module and waste heat recovery technology, which can be used in thermoelectric devices, thermoelectric device parts, generators/motors, etc., to solve problems such as power loss, and achieve the effect of improving output performance and improving thermoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0027] If the thermoelectric power generation module is used to recover waste heat generated by automobile exhaust, a complete thermoelectric generator consists of a heat exchanger, a thermoelectric power generation module and a cooler, and the thermoelectric power generation module is placed between the heat exchanger and the cooler.

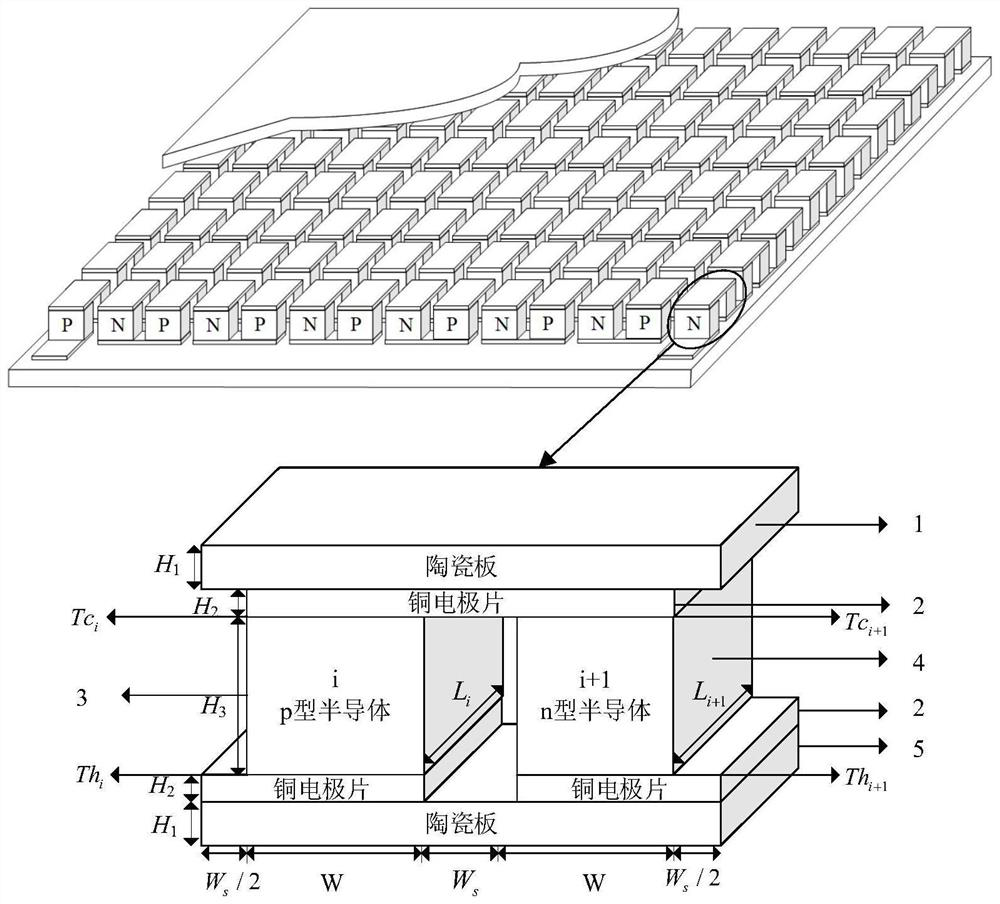

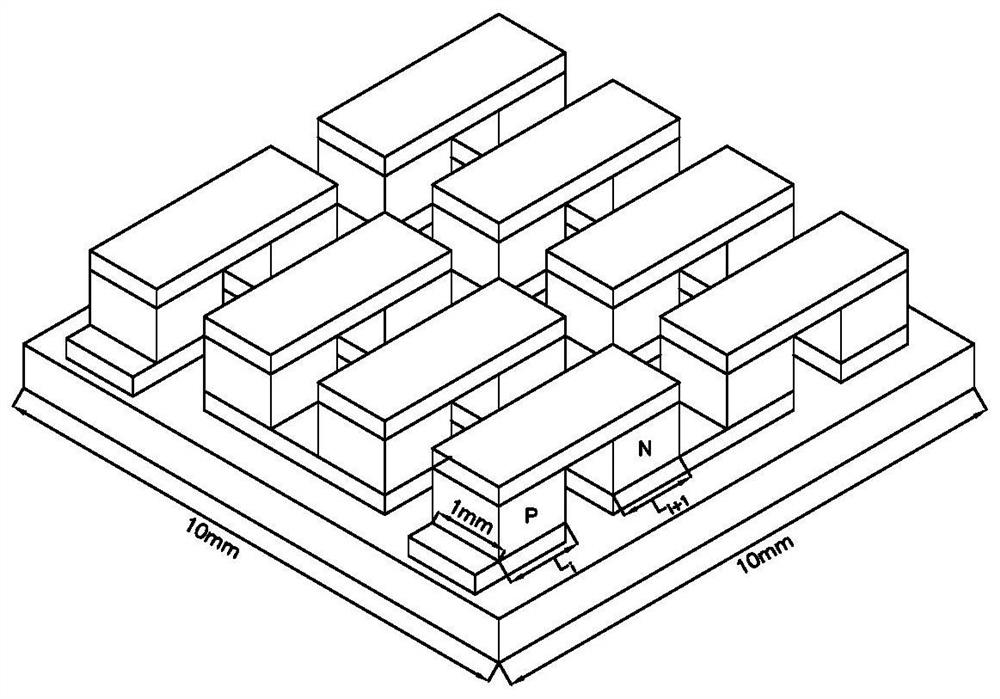

[0028] Such as figure 1 As shown, a thermoelectric power generation module for fluid waste heat recovery includes an upper alumina ceramic plate 1, a copper electrode sheet 2, a thermoelectric semiconductor and a lower alumina ceramic plate 5; wherein, the thermoelectric semiconductor includes a p-type thermoelectric semiconductor 3 and an n type thermoelectric semiconductor 4, and the p-type thermoelectric semiconductor 3 and n-type therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com