Arc groove rolling shaft friction support for underground subway station supporting column

A technology for subway stations and supporting columns, applied in the direction of underwater structures, artificial islands, building components, etc., can solve inconsistencies. For box-shaped subway stations, changes in the axial pressure ratio of the central column and the collapse of the roof underground structure system Destruction, weakening of shear deformation resistance and other problems, to achieve the effect of excellent work performance, strong vertical bearing capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

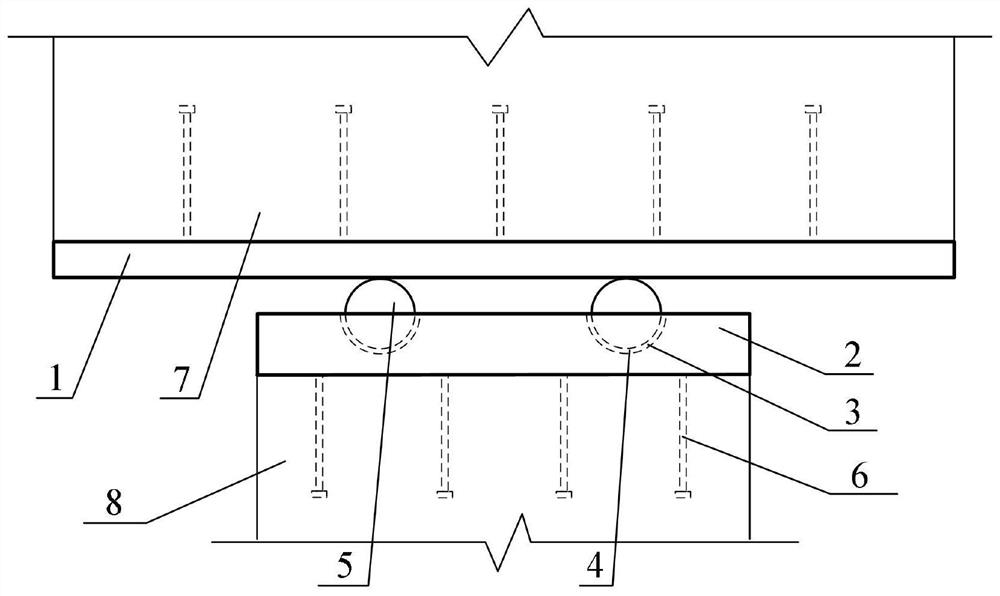

[0021] like figure 1 As shown in the figure, an arc groove roller friction bearing for supporting columns of an underground subway station is characterized in that the arc groove roller friction bearing is mainly composed of an upper seat plate (1) and a lower seat plate (2). ), a polytetrafluoroethylene arc plate (4) and a steel roller (5).

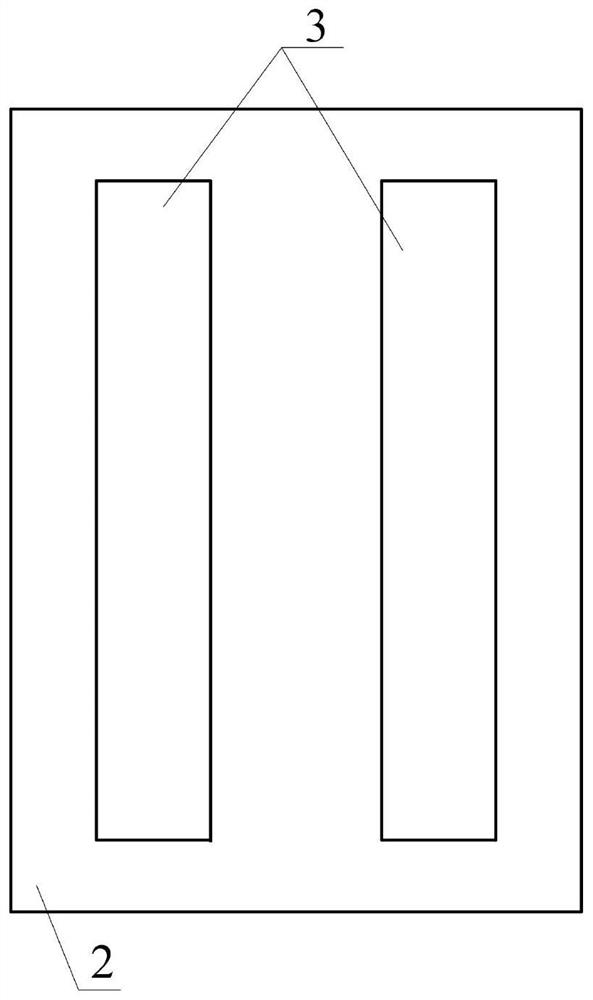

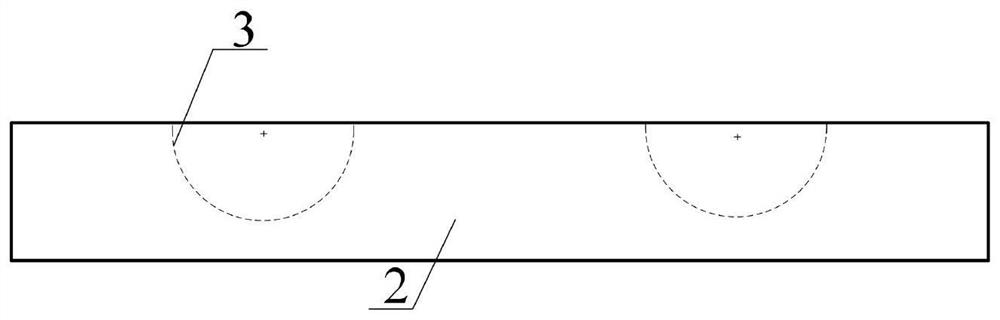

[0022] The anchor bars (6) are welded on the lower surface of the lower seat plate (2), and fixed on the top of the structural support column (8) by concrete casting, and the upper surface of the lower seat plate (2) is provided with a long strip circle An arc groove (3), the polytetrafluoroethylene arc plate (4) is fixedly installed in the elongated arc groove (3), and the steel roller (5) is placed in the polytetrafluoroethylene arc Inside the plate (4), sliding and rolling contact are formed with the PTFE arc plate (4) and the upper seat plate (1) respectively, and the anchor ribs (6) are welded on the upper surface of the upper seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com