Automatic position-adjustment laminating machine

An automatic positioning and laminating machine technology, which is applied to lamination devices, lamination auxiliary operations, lamination, etc., can solve problems such as low lamination efficiency and alignment errors, and achieve convenient operation, improved stability, and improved The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

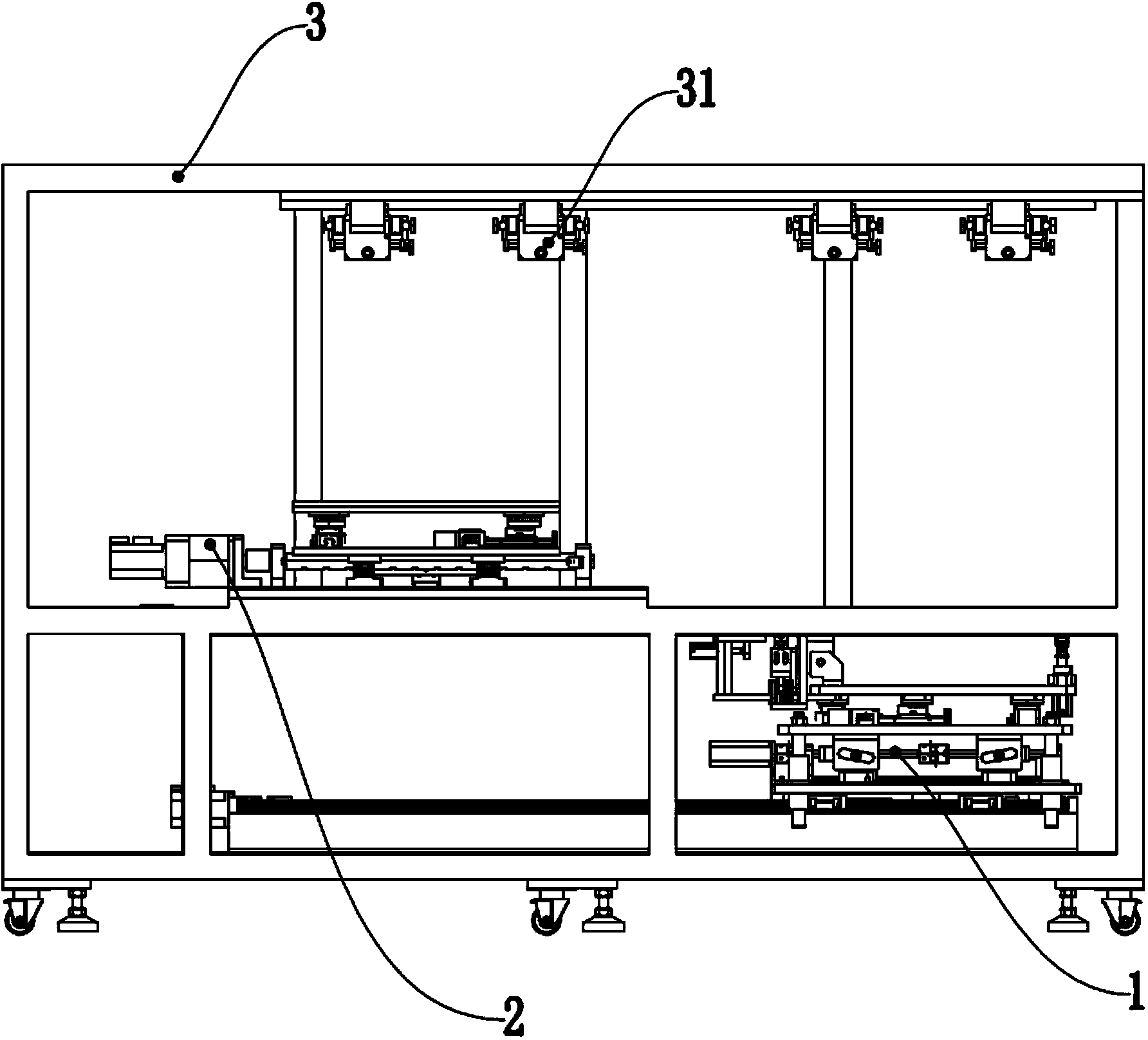

[0029] An automatic positioning and laminating machine, comprising a film stage mechanism 1, a pallet mechanism 2, a circuit board and a frame 3;

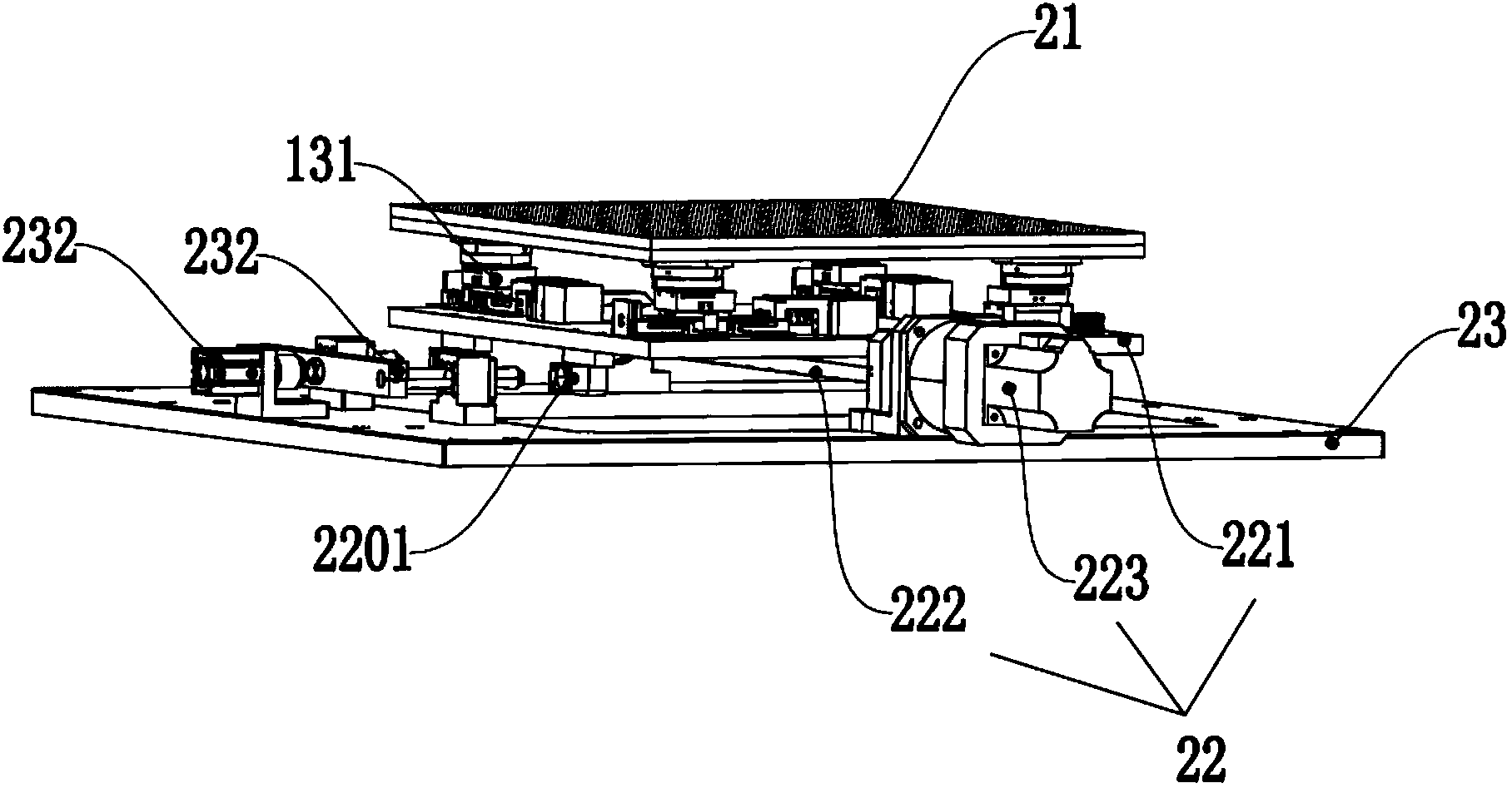

[0030] The pallet mechanism 2 includes a pallet 21 and a rotating assembly 22. The rotating assembly 22 includes a rotating plate 221, a rotating shaft 222 and a rotating motor 223. The pallet 21 is arranged just above the rotating plate 221. The rotating shaft 222 is fixedly mounted on the bottom surface of the rotating plate 221 , and the rotating shaft 222 is controlled by the rotating motor 223 ;

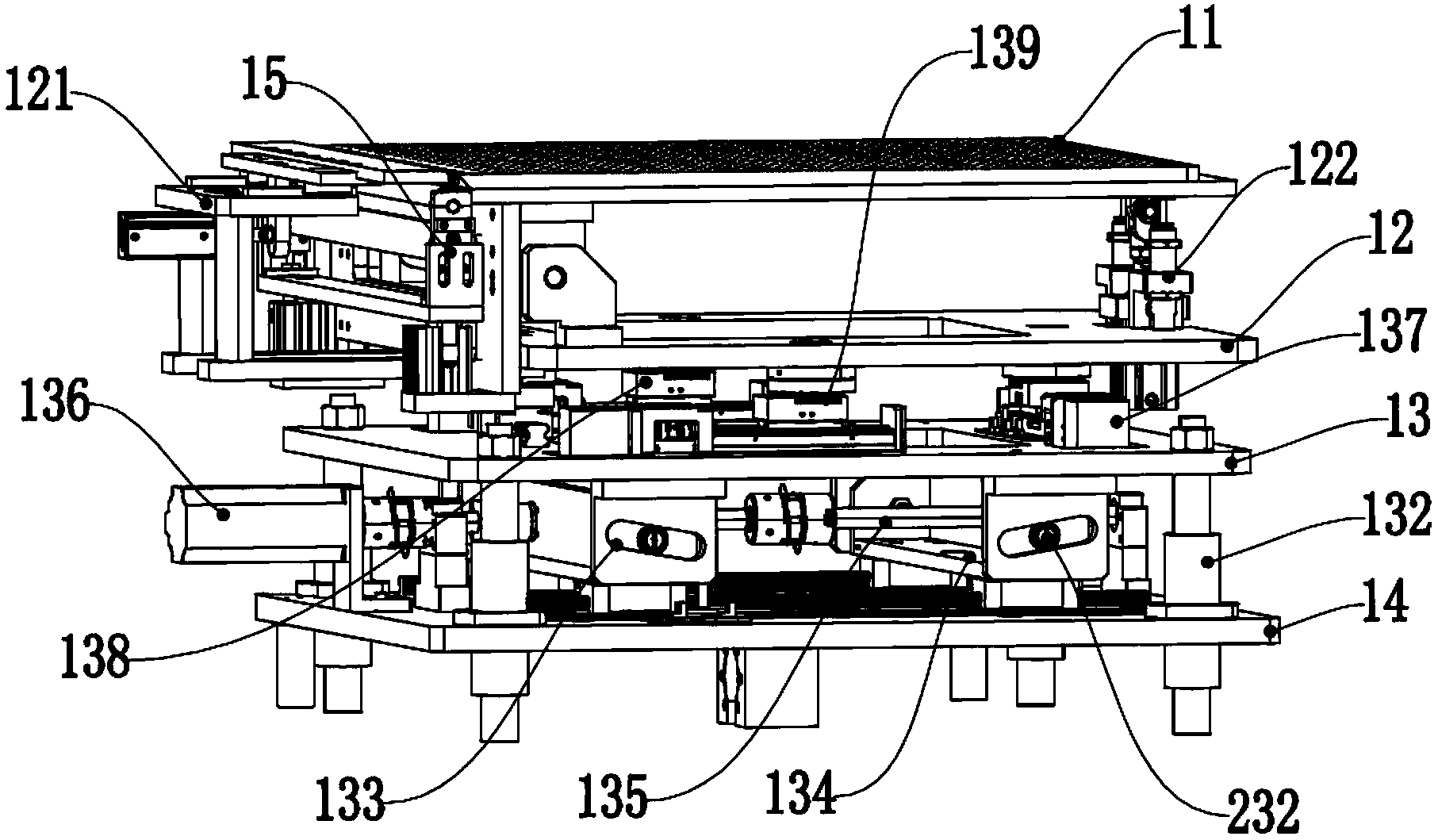

[0031] The film stage mechanism 1 includes a film stage 11 , an upper frame 12 , a middle frame 13 and a bottom frame 14 , the film stage 11 is arranged directly above the upper frame 12 , and the bottom surface of the upper frame 12 passes through a horizontal adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com