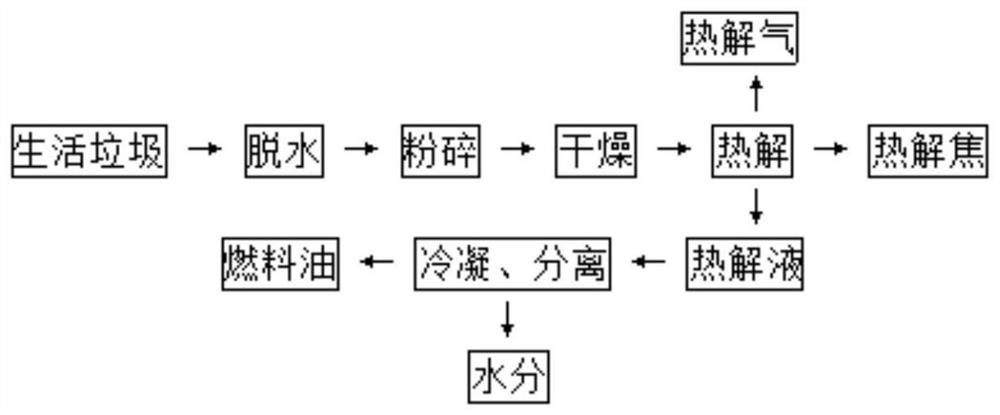

Household garbage pyrolysis gasification method

A technology of pyrolysis gasification and domestic waste, which is applied in the direction of gasification process, chemical modification of combustible gas, and heating treatment of combustible gas, which can solve the problems of uneven distribution of pyrolyzers and large energy consumption, and achieve energy saving effect Obvious, low energy consumption, the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

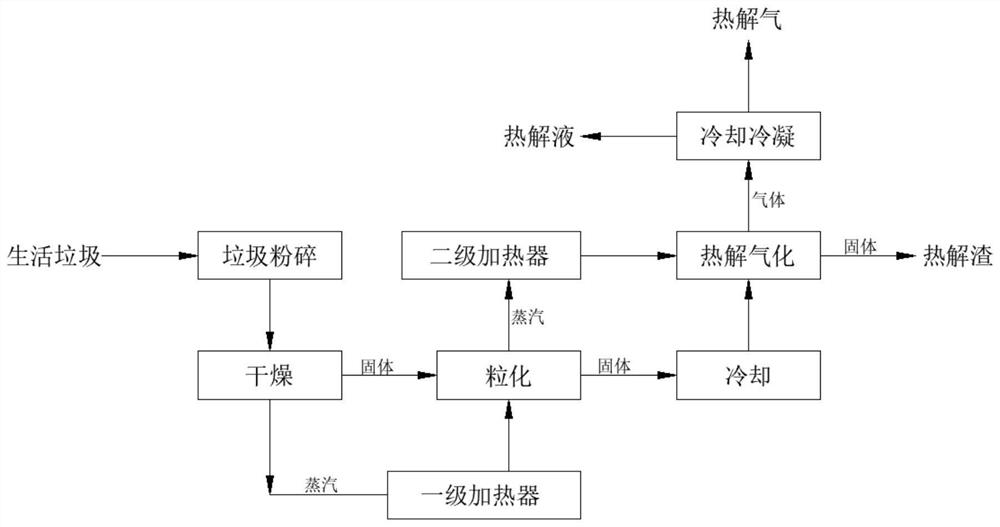

[0037] A method for pyrolysis and gasification of domestic waste, comprising the steps of:

[0038]Step 1. After the garbage is crushed, add it to the dryer for drying. The particle size of the garbage after crushing is 10-200mm. The temperature of the dryer is 80°C. The moisture content of the dried garbage is 15%. The steam of the dryer is sent to the first stage In the heater, the dried garbage is obtained for use;

[0039] Step 2. Transfer the dried garbage to the granulator, and transport the superheated steam in the primary heater to the granulator. The superheated steam will heat the dried garbage to 150°C and keep it for 60 minutes. The steam is sent to the secondary heater, and after cooling, the granular waste is obtained for use;

[0040] Step 3. Transfer the granular waste to the pyrolysis gasifier, and transport the steam in the secondary heater to the pyrolysis gasifier. The steam will pyrolyze the granular waste at 500°C for 60 minutes to generate heat Decompo...

Embodiment 2

[0043] A method for pyrolysis and gasification of domestic waste, comprising the steps of:

[0044] Step 1. After crushing the garbage, add it to the dryer for drying. The particle size of the garbage after crushing is 10-100mm. The temperature of the dryer is 100°C. The water content of the dried garbage is 12%. The steam of the dryer is sent to the first stage In the heater, the dried garbage is obtained for use;

[0045] Step 2. Transfer the dried garbage to the granulator, and transport the superheated steam in the primary heater to the granulator. The superheated steam will heat the dried garbage to 250°C and keep it for 35 minutes. The steam is sent to the secondary heater, and after cooling, the granular waste is obtained for use;

[0046] Step 3. Transfer the granular waste to the pyrolysis gasifier, and transport the steam in the secondary heater to the pyrolysis gasifier. The steam will pyrolyze the granular waste at 700°C for 40 minutes to generate heat Decomposin...

Embodiment 3

[0049] A method for pyrolysis and gasification of domestic waste, comprising the steps of:

[0050] Step 1. After crushing the garbage, add it to the dryer for drying. The particle size of the garbage after crushing is 10-100mm. The temperature of the dryer is 95°C. The water content of the dried garbage is 14%. The steam of the dryer is sent to the first stage In the heater, the dried garbage is obtained for use;

[0051] Step 2. Transfer the dried garbage to the granulator, and transport the superheated steam in the primary heater to the granulator. The superheated steam will heat the dried garbage to 250°C and keep it for 50 minutes. The steam is sent to the secondary heater, and after cooling, the granular waste is obtained for use;

[0052] Step 3. Transfer the granular waste to the pyrolysis gasifier, and transport the steam in the secondary heater to the pyrolysis gasifier. The steam will pyrolyze the granular waste at 700°C for 50 minutes to generate heat Decomposing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com