Efficient ultraviolet crosslinking low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

A technology of polyolefin cable material and ultraviolet light, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor cross-linking efficiency affecting cable performance, etc., and achieves easy preparation methods, good stability, and cross-linking. The effect of high connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

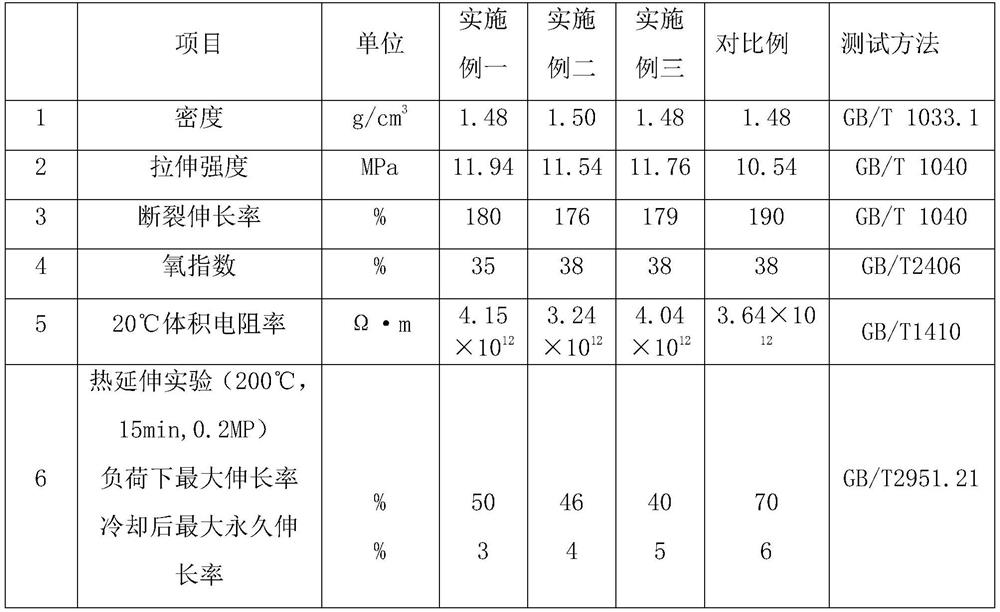

Embodiment 1

[0024] In parts by weight, 50 parts of polyethylene-vinyl acetate resin, 20 parts of ethylene-butylene copolymer, 20 parts of maleic anhydride grafted polyethylene resin, 5 parts of linear low-density polyethylene resin, 1 part of 4,4 '-thiobis(6-tert-butyl-3-methylphenol), 1 part polyethylene wax, 1 part benzophenone, 1 part 1-hydroxycyclohexyl phenyl ketone, and 5 parts trimethacrylic acid After the trimethylol propyl ester was stirred evenly in the mixer, it was added to the internal mixer, and then 150 parts of aluminum hydroxide was added to the internal mixer, and it was internally kneaded at 170° C. for 13 minutes. After banburying is completed, it is granulated by twin-screw and then single-screw to obtain highly efficient UV-crosslinked low-smoke, halogen-free, flame-retardant polyolefin cable compound.

Embodiment 2

[0026] In parts by weight, 45 parts of polyethylene-vinyl acetate resin, 22 parts of butadiene copolymer, 25 parts of polyethylene-vinyl acetate resin, 10 parts of low-density polyethylene resin, 1 part of 4,4'-sulfur Bis(6-tert-butyl-3-methylphenol), 1 part of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, 1.5 parts of polyethylene wax, 1 part of benzophenone , 2 parts of 2-hydroxyl-2-methyl-1-phenylacetone and 4 parts of ditrimethylolpropane tetraacrylate are stirred evenly in a mixer and then added to the internal mixer, and then 120 1 part of aluminum hydroxide and 60 parts of magnesium hydroxide, banburying at 170°C for 13 minutes. After banburying is completed, it is granulated by twin-screw and then single-screw to obtain highly efficient UV-crosslinked low-smoke, halogen-free, flame-retardant polyolefin cable compound.

Embodiment 3

[0028] In parts by weight, 30 parts of polyethylene-vinyl acetate resin, 30 parts of ethylene-butylene copolymer, 15 parts of maleic anhydride grafted polyethylene resin, 15 parts of high-density polyethylene resin, 2 parts of 4,4' - Thiobis(6-tert-butyl-3-methylphenol), 1 part polyethylene wax, 2 parts benzophenone, 2 parts 2-hydroxy-2-methyl-1-phenylacetone and 3 parts Stir trimethylolpropyl trimethacrylate evenly in a mixer and add it to the internal mixer, then add 160 parts of aluminum hydroxide and 20 parts of magnesium hydroxide to the internal mixer, and banbury at 170 ° C for 13 minutes . After banburying is completed, it is granulated by twin-screw and then single-screw to obtain highly efficient UV-crosslinked low-smoke, halogen-free, flame-retardant polyolefin cable compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com