Polyurethane resin for medium-soft organic silicon modified high-physical-property surface layer and preparation method of polyurethane resin

A polyurethane resin and organosilicon technology is applied in the field of polyurethane resin for modified high-physical property surface layer of medium-soft organosilicon and its preparation field. It can ensure the flexural resistance, eliminate the existence of free small molecular silicone oil, and achieve the effect of soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

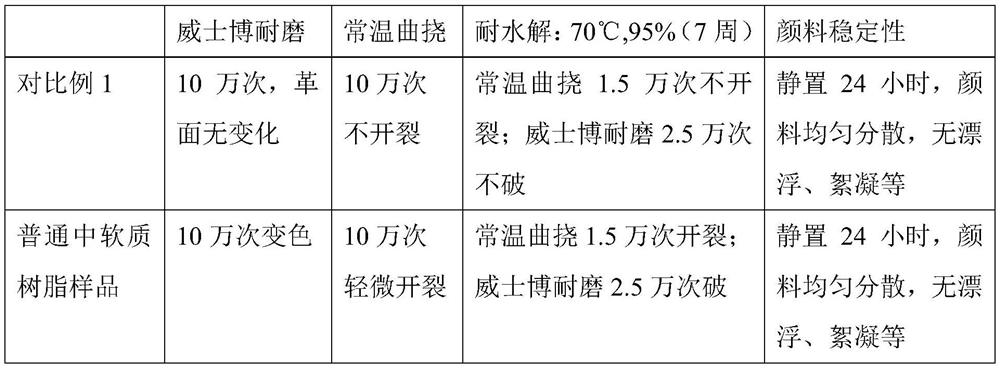

Embodiment 1

[0057] Add 72 parts of polycarbonate polyol (molecular weight 2000) and 28 parts of polyether polyol (molecular weight 2000) into the reaction kettle, heat the reaction kettle to 100°C, vacuum dehydrate for about 1 hour, and cool down to 50°C; Add 150 parts of dimethylformamide, 1.1 parts of 1,4-butanediol, 6.8 parts of ethylene glycol, and 35 parts of diphenylmethane diisocyanate, stir evenly, raise the temperature to 70°C, and react for about 50 minutes; then add 6 Parts of diaminopolysiloxane, reacted at 70°C for 50 minutes; then, added 4 parts of diphenylmethane diisocyanate at 70°C, reacted for 20 minutes, added 0.02 parts of organic bismuth catalyst, and continued to react for 30 minutes; Add the remaining 4.3 parts of diphenylmethane diisocyanate in batches to the reaction kettle for chain extension reaction. The feeding interval of each step is 40-60 minutes, and the reaction temperature is 70°C. Dilution is performed in three steps, viscosification and dilution are ca...

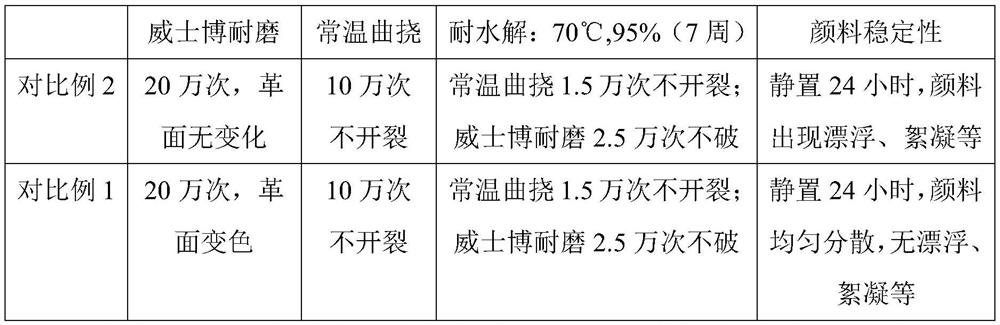

Embodiment 2

[0064] Add 72 parts of polycarbonate polyol (molecular weight 2000) and 28 parts of polyether polyol (molecular weight 2000) into the reaction kettle, heat the reaction kettle to 100°C, vacuum dehydrate for about 1 hour, and cool down to 50°C; Add 150 parts of dimethylformamide, 1.1 parts of 1,4-butanediol, 6.8 parts of ethylene glycol, and 35 parts of diphenylmethane diisocyanate, stir evenly, raise the temperature to 70°C, and react for about 50 minutes; then add 3 Parts of diaminopolysiloxane, reacted at 70°C for 50 minutes; then, added 4 parts of diphenylmethane diisocyanate at 70°C, reacted for 20 minutes, added 0.02 parts of organic bismuth catalyst, and continued to react for 30 minutes; Add the remaining 4.2 parts of diphenylmethane diisocyanate in batches to the reaction kettle for chain extension reaction. The feeding interval of each step is 40-60 minutes, and the reaction temperature is 70°C. Dilution is performed in three steps, viscosification and dilution are ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com