Preparation method of fish feed with high bioavailability

A technology of availability and fish feed, applied in the molding or processing of animal feed, animal feed, application, etc., can solve the problems of low digestion and absorption rate, nutrient loss, low feed utilization rate, etc., and achieve high bioavailability, The effect of reducing losses and eliminating waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

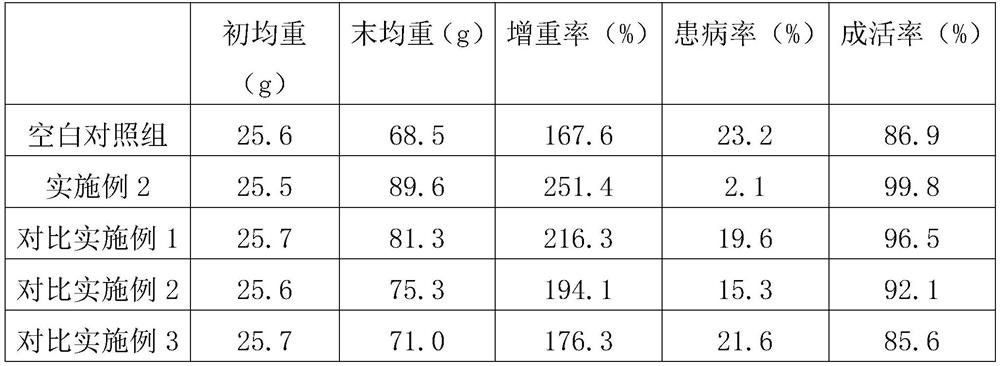

Examples

Embodiment 1

[0035] A method for preparing fish feed with high bioavailability, comprising the steps of:

[0036] (1) Weighing of raw materials:

[0037] Weigh 45 parts of corn, 23 parts of wheat, 6 parts of soybean, 10 parts of rapeseed cake, 5 parts of fishmeal, 2 parts of purslane, 8 parts of bran, 6 parts of additives, and 30 parts of pure water in corresponding parts by weight;

[0038] (2) Flame treatment:

[0039] The corn, wheat, soybean, rapeseed cake, fishmeal, purslane, bran, and pure water weighed in step (1) are mixed and placed on the flame for processing, and the mixture is obtained after processing for 20 minutes for subsequent use;

[0040] (3) Microjet high-pressure homogenization treatment:

[0041] The mixture obtained in step (2) is placed in a micro-jet high-pressure homogenizer for high-pressure homogenization treatment, and a homogeneous product is obtained after completion for subsequent use;

[0042] (4) Crushing treatment:

[0043] The homogeneous product obt...

Embodiment 2

[0062] A method for preparing fish feed with high bioavailability, comprising the steps of:

[0063] (1) Weighing of raw materials:

[0064] Weigh 50 parts of corn, 26 parts of wheat, 7 parts of soybean, 12 parts of rapeseed cake, 7 parts of fishmeal, 2.5 parts of purslane, 10 parts of bran, 7 parts of additives, and 40 parts of pure water in corresponding parts by weight;

[0065] (2) Flame treatment:

[0066] The corn, wheat, soybean, rapeseed cake, fishmeal, purslane, bran, and pure water weighed in the step (1) are mixed and placed on the flame for processing, and the mixture is obtained after processing for 25 minutes for subsequent use;

[0067] (3) Microjet high-pressure homogenization treatment:

[0068] The mixture obtained in step (2) is placed in a micro-jet high-pressure homogenizer for high-pressure homogenization treatment, and a homogeneous product is obtained after completion for subsequent use;

[0069] (4) Crushing treatment:

[0070] The homogeneous prod...

Embodiment 3

[0089] A method for preparing fish feed with high bioavailability, comprising the steps of:

[0090] (1) Weighing of raw materials:

[0091] Weigh 55 parts of corn, 29 parts of wheat, 8 parts of soybeans, 14 parts of rapeseed cake, 9 parts of fishmeal, 3 parts of purslane, 12 parts of bran, 8 parts of additives, and 50 parts of pure water in corresponding parts by weight;

[0092] (2) Flame treatment:

[0093] The corn, wheat, soybean, rapeseed cake, fishmeal, purslane, bran, and pure water weighed in the step (1) are mixed and placed on the flame for processing, and the mixture is obtained after processing for 30 minutes for subsequent use;

[0094] (3) Microjet high-pressure homogenization treatment:

[0095] The mixture obtained in step (2) is placed in a micro-jet high-pressure homogenizer for high-pressure homogenization treatment, and a homogeneous product is obtained after completion for subsequent use;

[0096] (4) Crushing treatment:

[0097] The homogeneous produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com