A laser beam combining system based on a square fiber beam combiner

An optical fiber combiner and laser beam combining technology, applied in lasers, laser devices, laser parts and other directions, can solve problems such as poor stability, inconvenient thermal management, and difficult to solve heat dissipation problems, so as to improve stability and facilitate heat dissipation. Management, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

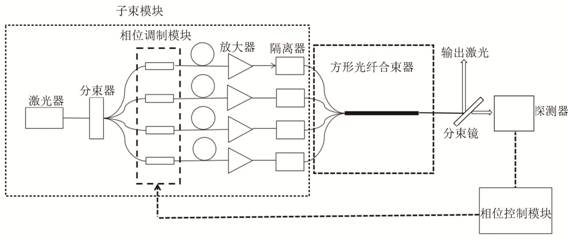

[0032] In this example, if figure 1 The coherent combining of 4 optical fibers is shown as an example. The 4 optical fibers are arranged into a 2*2 array in the beam combiner, the square optical fiber is divided into 4 square sub-areas, and the 4 optical fibers are combined with the corresponding areas in the square optical fiber. Make a vertical connection and ensure that the center of the fiber coincides with the center of the corresponding square sub-area. After the output beams of the 4 optical fibers are combined through the square fiber combiner of the present invention, the combined beam quality M 2 =1.16, the beam combining efficiency of the laser beam combining system is 99.3%, and according to figure 2 It can be seen that the beam synthesized in this embodiment has no beam side lobes.

Embodiment 2

[0034] In this embodiment, taking the coherent combination of 9 optical fibers as an example, arrange the 9 optical fibers into a 3*3 array, divide the square optical fiber into 9 square sub-areas, and divide the 9 optical fibers into the corresponding square sub-areas in the square optical fiber. The area is connected vertically, and the center of the optical fiber coincides with the center of the corresponding square sub-area. After the output lasers of the 9 optical fibers are combined through the square optical fiber combining module of the present invention, the combined beam quality M 2 If it is less than 1.3, the beam combining efficiency of the laser beam combining system is greater than 99%.

[0035] In summary, it can be seen that the laser beam combining system disclosed in the present invention can realize the laser beam combining technology based on the principle of optical waveguide self-imaging with a simple structure. The beam quality after beam combining is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com