Preparation method of compound-modified glass micron pore channel and method for separating alkali metal ions by using same

An alkali metal ion and compound technology, which is applied in glass manufacturing equipment, glass molding, glass re-molding, etc., can solve the problems of high energy consumption of glass micro-channels, inconvenient use, low promotion value, etc., and achieve repeatability. Detect the effect of use, high effectiveness, and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

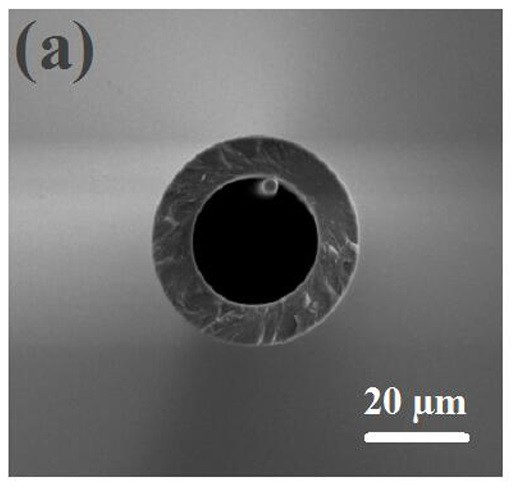

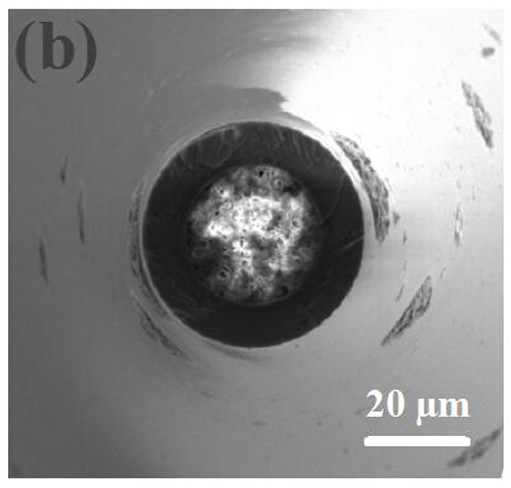

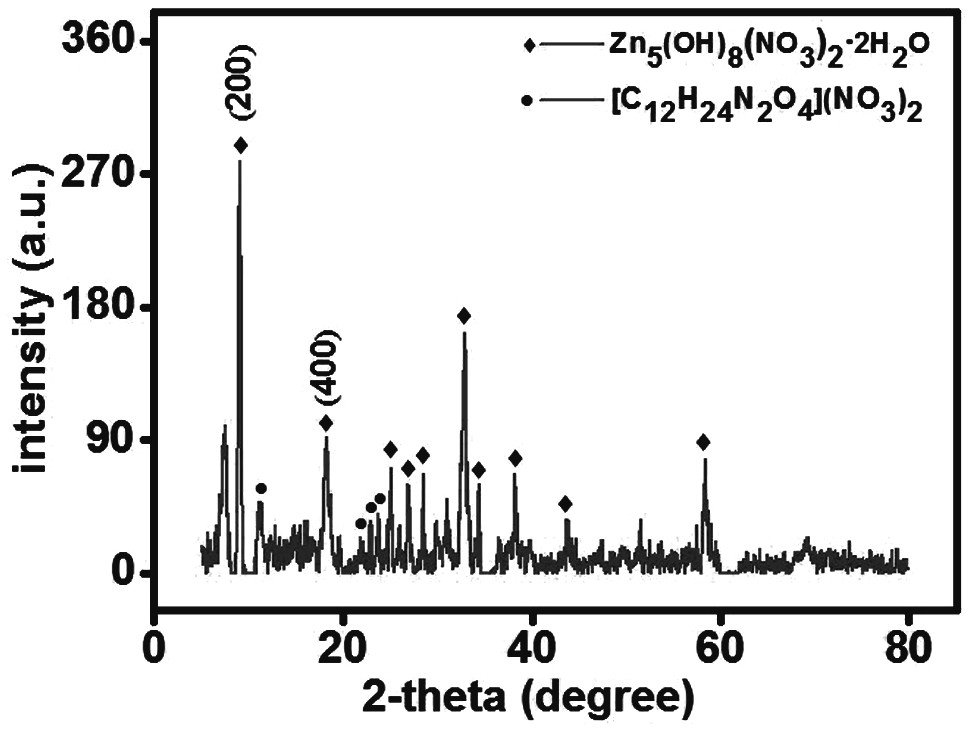

[0054] Such as Figure 1a , 1b Shown, specifically: Z 5 HN@DAC 12 N 4 o 10 A method for preparing composite-modified glass micro-pores and a method for separating alkali metal ions using the same, comprising the following steps:

[0055] Step 1: preparing glass micrometer channels;

[0056] Step 2: Prepared to be able to react to generate Z 5 HN@DAC 12 N 4 o 10 The A and B solutions of the complex, wherein the A solution is a solution of 4,13-diaza-18-crown-6, and the B solution is a solution of zinc nitrate hexahydrate,

[0057] Step 3: Prepare Z 5 HN@DAC 12 N 4 o 10 Composite-modified glass micro-pores;

[0058] Use the injection needle to inject a certain volume of A solution into the tail of the glass microtube prepared in step 1, then insert the glass microtube injected with A solution into the B solution, draw a certain amount of B solution, and let the A and B solutions in the glass The tip of the microtube reacts to form Z 5 HN@DAC 12 N 4 o 10 composi...

Embodiment

[0065] see Figure 4 shown, based on Z 5 HN@DAC 12 N 4 o 10 Preparation method of composite-modified glass micro-pores:

[0066] Step 1: Prepare glass micron channels by P-97 glass drawing instrument;

[0067] Among them, the glass micro-channel drawing condition parameters are shown in Table 1 below, and the nano-pore diameter obtained through SEM characterization is about 23±3 μm.

[0068] Table 1 Drawing Condition Parameter Diagram of Glass Micro-channel

[0069]

[0070]

[0071] Step 2: Prepare a functional Z that can react to form 5 HN@DAC 12 N 4 o 10 Complex, the operation method is as follows: first weigh 104.9mg of 4,13-diaza-18-crown-6 dissolved in 5mL of dichloromethane and 5mL of methanol solution marked as solution A, followed by 185.8mg of Zn (NO 3 ) 2 ·6H 2 O was dispersed in 10 mL methanol solution as B solution. Then shake the A and B solutions evenly under an ultrasonic instrument, and seal them with a sealing film before placing them in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com